Time: 2026-01-05 08:00:50 Source: Henan Province Jianyun Cable Co., Ltd.

Choosing between copper and aluminum for electrical cables is a key decision in residential, commercial, and industrial projects. Both materials are widely used in electrical cables, but they differ significantly in conductivity, cost, weight, and durability. This comprehensive 2026 comparison helps you understand the strengths and weaknesses of copper vs aluminum electrical cables to make an informed choice.

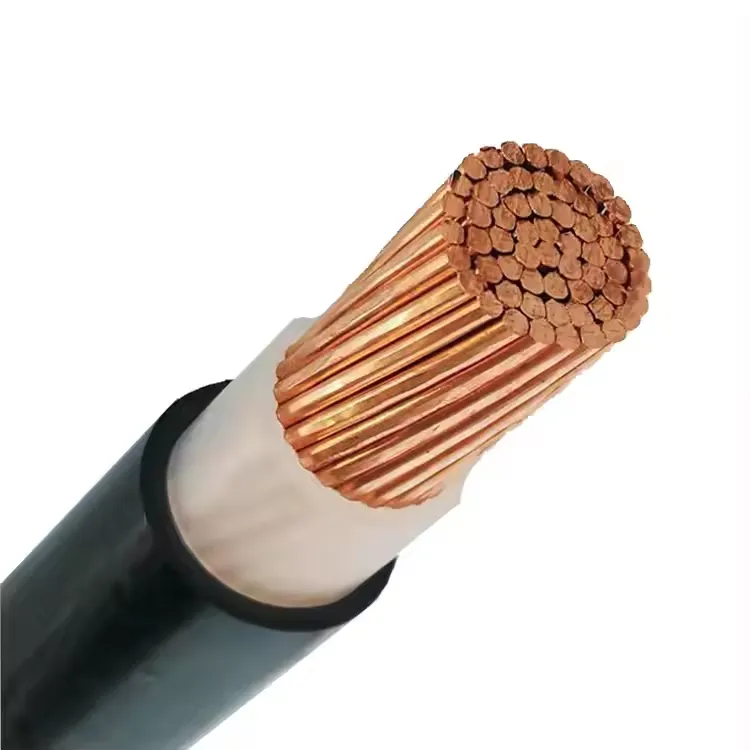

Copper has long been the standard for electrical cables due to superior conductivity, while aluminum offers a lightweight, cost-effective alternative. Modern aluminum alloys (e.g., AA-8000 series) have improved reliability, making aluminum electrical cables viable for many applications beyond large feeders.

Copper conducts electricity about 61% better than aluminum (IACS standard). This means copper electrical cables can carry more current in the same size or use smaller conductors for equivalent ampacity. Aluminum requires roughly 50% larger cross-section to match copper performance, but modern designs optimize this gap.

Aluminum electrical cables are typically 30–50% cheaper per meter than copper, with even greater savings in large projects due to lower material costs. However, total installed cost may vary with terminations and supports needed for aluminum.

Aluminum is about one-third the weight of copper, making aluminum electrical cables easier to handle, especially in long runs or overhead lines. This reduces labor and support structure costs but requires careful termination to prevent creep.

Copper resists corrosion better, particularly in moist environments. Aluminum forms an oxide layer that protects it but can cause connection issues if not properly terminated. Modern anti-oxidant compounds and compatible lugs have largely resolved these concerns for aluminum electrical cables.

Historical issues with aluminum wiring (1960s–70s) led to fires from poor connections, but today's approved aluminum alloys and CO/ALR devices make them safe when installed correctly. Copper electrical cables have a proven track record with fewer connection problems.

| Factor | Copper Electrical Cables | Aluminum Electrical Cables |

|---|---|---|

| Conductivity | Excellent (100% IACS) | Good (61% IACS) |

| Cost | Higher | 30–50% lower |

| Weight |

CE Certification 450/750v H07VVF Flexible Copper PVC Insulated Ac Cable 3*2.5 Mm

low voltage copper conductor PVC insulation underground BV BVR cable for industr

PVC electric wires are one of the most widely used electrical conductors in resi

H07V-U wire is a flexible, low voltage electrical wire commonly used in industri