Time: 2026-02-05 11:45:36 Source: Henan Province Jianyun Cable Co., Ltd.

By Jianyun Cable – Professional Manufacturer of Quality Electrical Cables

Choosing the correct low voltage power cable (typically 0.6/1 kV or below) is critical for safety, performance, longevity, and cost-effectiveness. A wrong selection can cause overheating, voltage drop, premature failure, safety hazards, or unnecessary expense. This practical 2025 guide walks you through the key decision steps and factors to select the right LV cable for residential, commercial, industrial, or infrastructure projects.

Most low voltage projects fall into these categories:

Always select cables with a rated voltage ≥ system voltage (e.g., 0.6/1 kV cable for 400 V systems).

Determine:

Use this to select conductor cross-section later (after derating).

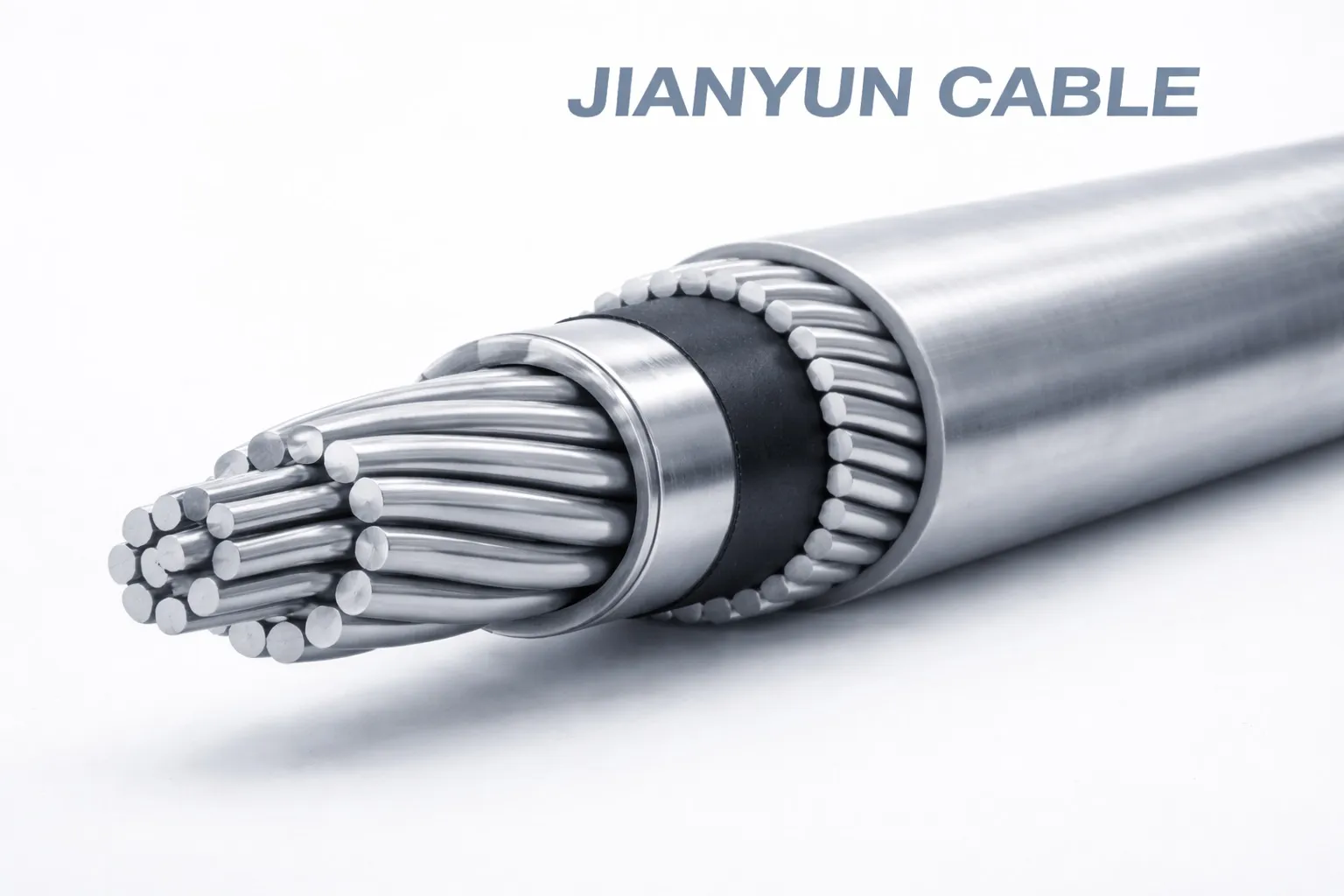

| Parameter | Copper Conductor | Aluminum Conductor |

|---|---|---|

| Conductivity | Higher (100% IACS) | Lower (~61% IACS) |

| Cross-section needed for same current | Smaller | ≈1.6× larger |

| Weight | Heavier | Much lighter |

| Cost (2025 material prices) | Higher per kg | Lower per kg – often cheaper overall for large sizes |

| Corrosion resistance | Good | Good with proper termination |

| Typical use | Indoor, short runs, critical circuits | Long feeders, underground, large cross-sections |

Key questions:

Match cable construction to actual conditions (e.g., LSOH in tunnels, water-blocked underground, UV-resistant aerial).

Use current-carrying capacity tables from standards (IEC 60364-5-52, NEC Table 310.16, AS/NZS 3008, etc.) and apply derating:

Also check voltage drop (typically max 3–5%).

Common low voltage standards:

Look for third-party certification marks (e.g., BASEC, VDE, UL, SAA, CCC).

| Application | Recommended Conductor | Insulation | Armouring | Sheath |

|---|---|---|---|---|

| Indoor fixed wiring (offices, shops) | Copper | PVC or XLPE | None | PVC |

| Underground / direct burial | Copper or Aluminum | XLPE | SWA / STA | PVC / PE |

| Industrial – oil / chemical exposure | Copper | XLPE / EPR | SWA | CSP / CPE |

| Public buildings / tunnels | Copper | XLPE | SWA or none | LSZH / LSOH |

| Solar PV DC cables | Copper (tinned) | XLPE / special | None | UV-resistant XLPE |

Selecting the right low voltage power cable is a systematic process that balances electrical performance, mechanical protection, environmental resistance, safety, and cost. Always start with load current and installation conditions, then work through conductor material, insulation type, armouring, and standards compliance. When in doubt, consult manufacturer datasheets, local codes, and a qualified electrical engineer. The correct choice ensures safe, efficient, and long-lasting performance — often for 30–50 years or more.

Need help selecting the perfect low voltage cable for your next project? Contact Henan Province Jianyun Cable Co., Ltd. — your trusted partner for high-quality LV power cables manufactured to international standards.

CE Certification 450/750v H07VVF Flexible Copper PVC Insulated Ac Cable 3*2.5 Mm

low voltage copper conductor PVC insulation underground BV BVR cable for industr

PVC electric wires are one of the most widely used electrical conductors in resi

H07V-U wire is a flexible, low voltage electrical wire commonly used in industri