Time: 2026-02-03 15:31:10 Source: Henan Province Jianyun Cable Co., Ltd.

By Jianyun Cable – Professional Manufacturer of Quality Electrical Cables

Correct cable laying is one of the most important factors determining whether a power cable will achieve its expected service life of 30–50 years. Poor installation techniques cause more premature cable failures than manufacturing defects. This 2025 guide explains the main cable laying methods used in power distribution and industrial projects, together with best practices to minimize damage and maximize reliability.

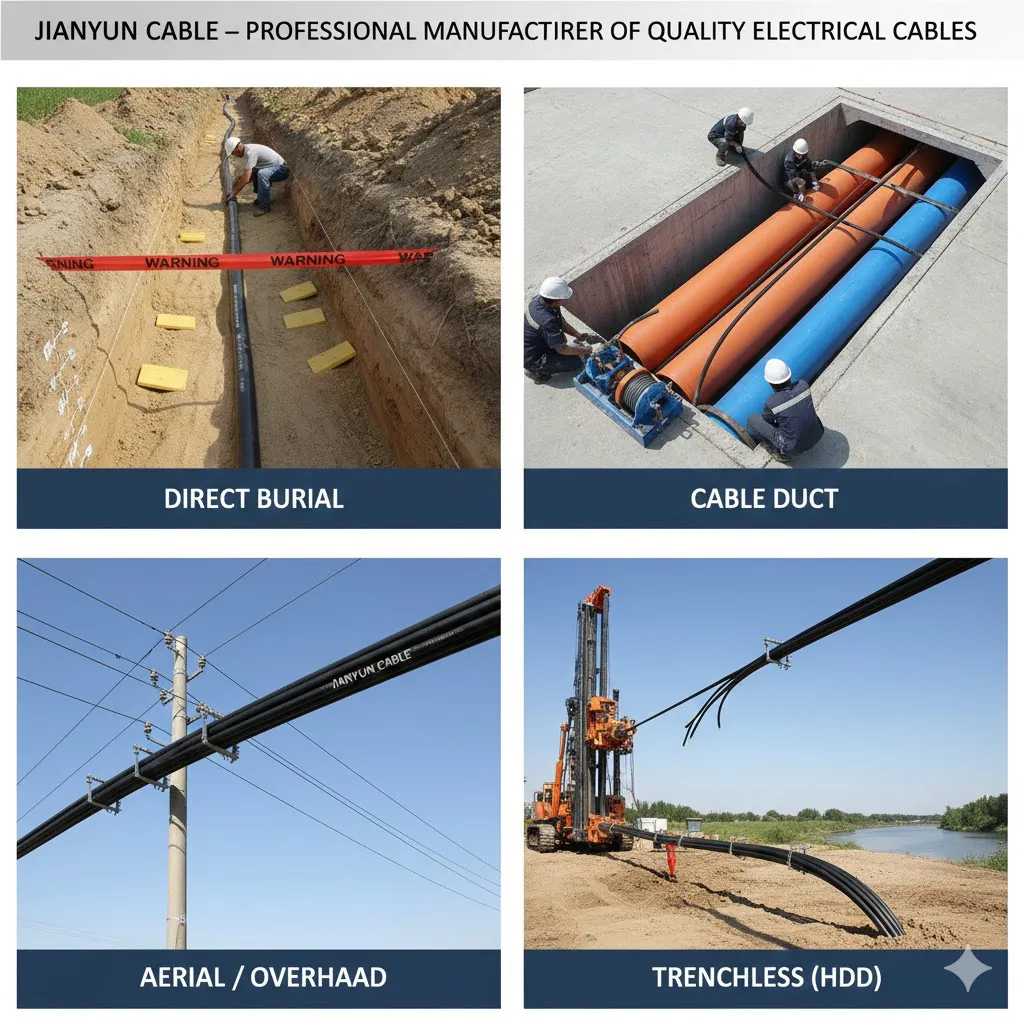

Power cables are installed using one of four primary methods, each suited to different environments and project requirements:

| Method | Typical Application | Mechanical Protection Level | Cost Level | Most Suitable Cable Type |

|---|---|---|---|---|

| Direct Burial | Rural, urban distribution, industrial sites | High (armoured cables) | Medium | SWA / AWA / STA armoured |

| Cable Duct / Pipe | Urban networks, crossings, future-proofing | Very High | High | Unarmoured or light-armoured |

| Aerial / Overhead | Rural lines, temporary installations | Low–Medium | Low–Medium | ABC (Aerial Bundled Conductor), covered conductor |

| Trenchless (HDD, Pipe Jacking) | River / road crossings, urban areas | High (in duct) | Very High | HDPE duct + unarmoured cable |

Most common method for armoured power cables.

Best practices:

Used when future upgrades or high mechanical protection is required.

Best practices:

Mainly for low- and medium-voltage distribution.

Best practices:

Key points:

Most cable damage occurs during pulling.

| Parameter | Low Voltage (≤1 kV) | Medium Voltage (6–35 kV) | High Voltage (>35 kV) |

|---|---|---|---|

| Minimum Bending Radius (during installation) | 8–10 × Ø | 12–15 × Ø | 15–20 × Ø |

| Minimum Bending Radius (final position) | 6–8 × Ø | 10–12 × Ø | 12–15 × Ø |

| Typical Direct Burial Depth | 0.6–0.8 m | 0.9–1.2 m | 1.2–1.8 m |

| Max Pulling Tension (example) | 30–50 N/mm² conductor area | 50–70 N/mm² | 50–80 N/mm² |

Proper cable laying is as important as cable quality itself. Mistakes during installation are irreversible and often cause the majority of early cable failures. By selecting the right laying method, respecting mechanical limits, using correct bedding and protection, and performing thorough testing, you can ensure power cables deliver reliable performance for decades.

Quick Cable Laying Checklist:

Need high-quality power cables and professional advice for your next cable laying project? Contact Henan Province Jianyun Cable Co., Ltd. — your trusted partner for reliable cables and installation support.

CE Certification 450/750v H07VVF Flexible Copper PVC Insulated Ac Cable 3*2.5 Mm

low voltage copper conductor PVC insulation underground BV BVR cable for industr

PVC electric wires are one of the most widely used electrical conductors in resi

H07V-U wire is a flexible, low voltage electrical wire commonly used in industri