Time: 2026-02-02 12:21:23 Source: Henan Province Jianyun Cable Co., Ltd.

By Jianyun Cable – Professional Manufacturer of Quality Electrical Cables

Underground and direct burial power cables supply electricity to homes, commercial buildings, industrial sites, solar farms, wind parks, and street lighting — often in environments that are wet, corrosive, and mechanically demanding. Choosing the right cable is critical for long-term reliability, safety, and cost-effectiveness. This guide explains what to look for when selecting power cables for underground and direct burial use in 2025.

Buried cables face unique threats:

Only cables specifically engineered for these conditions can deliver 30–50 years of safe service.

Common cable constructions suitable for underground/direct burial:

| Cable Type | Construction | Best For | Direct Burial Without Extra Protection? | Typical Voltage Range |

|---|---|---|---|---|

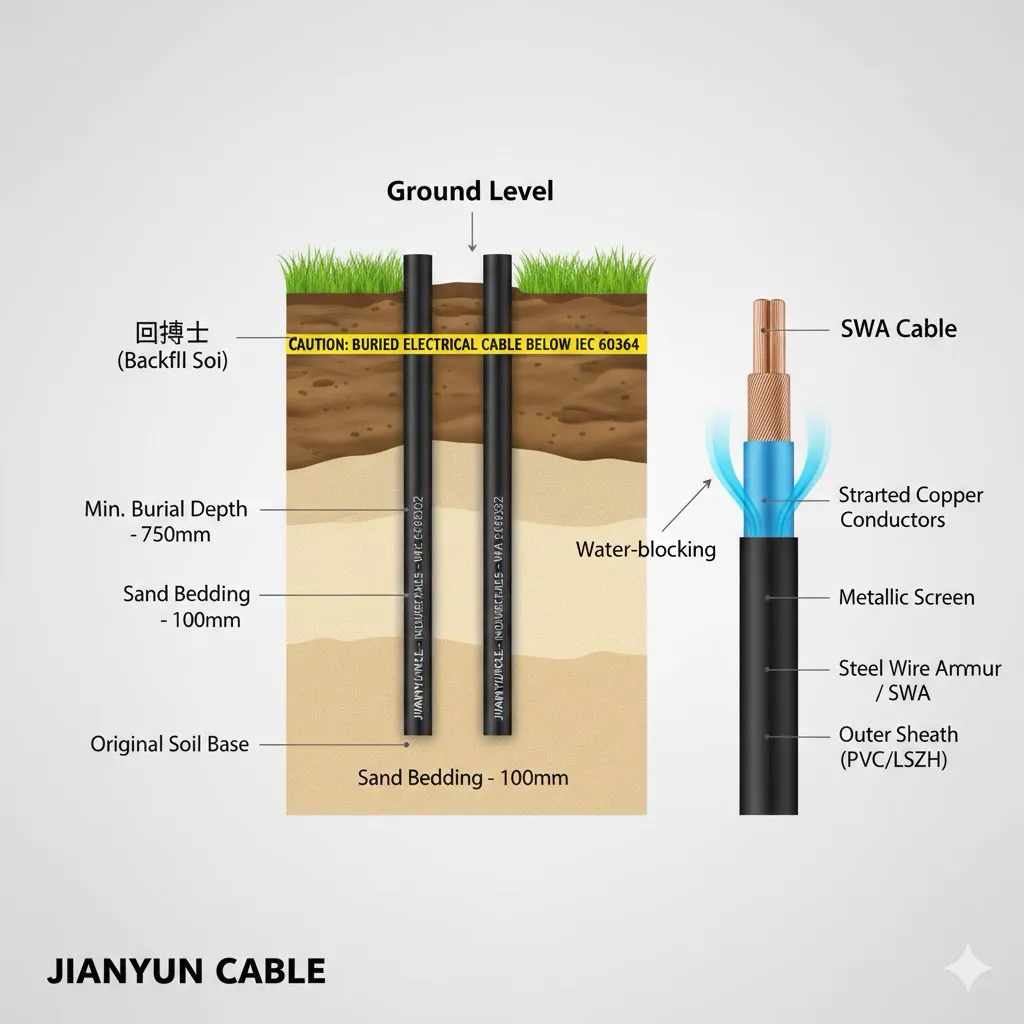

| SWA (Steel Wire Armoured) | XLPE insulation + copper/aluminum conductors + steel wire armour + PVC/LSOH sheath | Most direct burial power distribution | Yes – most common choice | 0.6/1 kV – 35 kV |

| AWA (Aluminum Wire Armoured) | Similar to SWA but with aluminum armour | Single-core cables (to avoid magnetic losses) | Yes | 0.6/1 kV – 35 kV |

| STA (Steel Tape Armoured) | Steel tape armour (often double layer) | Cost-sensitive projects, less mechanical stress | Yes in many regions | 0.6/1 kV – 18/30 kV |

| Unarmoured + HDPE Sheath | XLPE insulation + thick, tough HDPE outer sheath | Ducts or sand-bedded trenches | No – requires duct or sand bedding | 0.6/1 kV – 35 kV |

| Water-Blocked Unarmoured | Strong water-blocking layers + HDPE or LSOH sheath | Duct installations with high groundwater | No – duct or conduit required | 0.6/1 kV – 66 kV |

Water is the #1 long-term enemy of buried cables. Effective water-blocking prevents longitudinal migration along the core, limiting damage even if the outer sheath is compromised.

Most modern direct-burial power cables combine both armour and water-blocking for maximum protection.

Choosing the right power cable for underground and direct burial installations is about balancing mechanical protection, moisture resistance, and long-term reliability. Armoured cables with water-blocking features (especially SWA with swellable layers) remain the most trusted and widely accepted solution for direct burial worldwide. Investing in the correct cable type and following proper installation practices significantly reduces the risk of costly failures and ensures decades of safe, uninterrupted power delivery.

Need reliable underground and direct burial power cables manufactured to the highest standards? Contact Henan Province Jianyun Cable Co., Ltd. — your professional partner for SWA, AWA, water-blocked, and custom buried cable solutions.

CE Certification 450/750v H07VVF Flexible Copper PVC Insulated Ac Cable 3*2.5 Mm

low voltage copper conductor PVC insulation underground BV BVR cable for industr

PVC electric wires are one of the most widely used electrical conductors in resi

H07V-U wire is a flexible, low voltage electrical wire commonly used in industri