Time: 2026-02-03 15:00:37 Source: Henan Province Jianyun Cable Co., Ltd.

By Jianyun Cable – Professional Manufacturer of Quality Electrical Cables

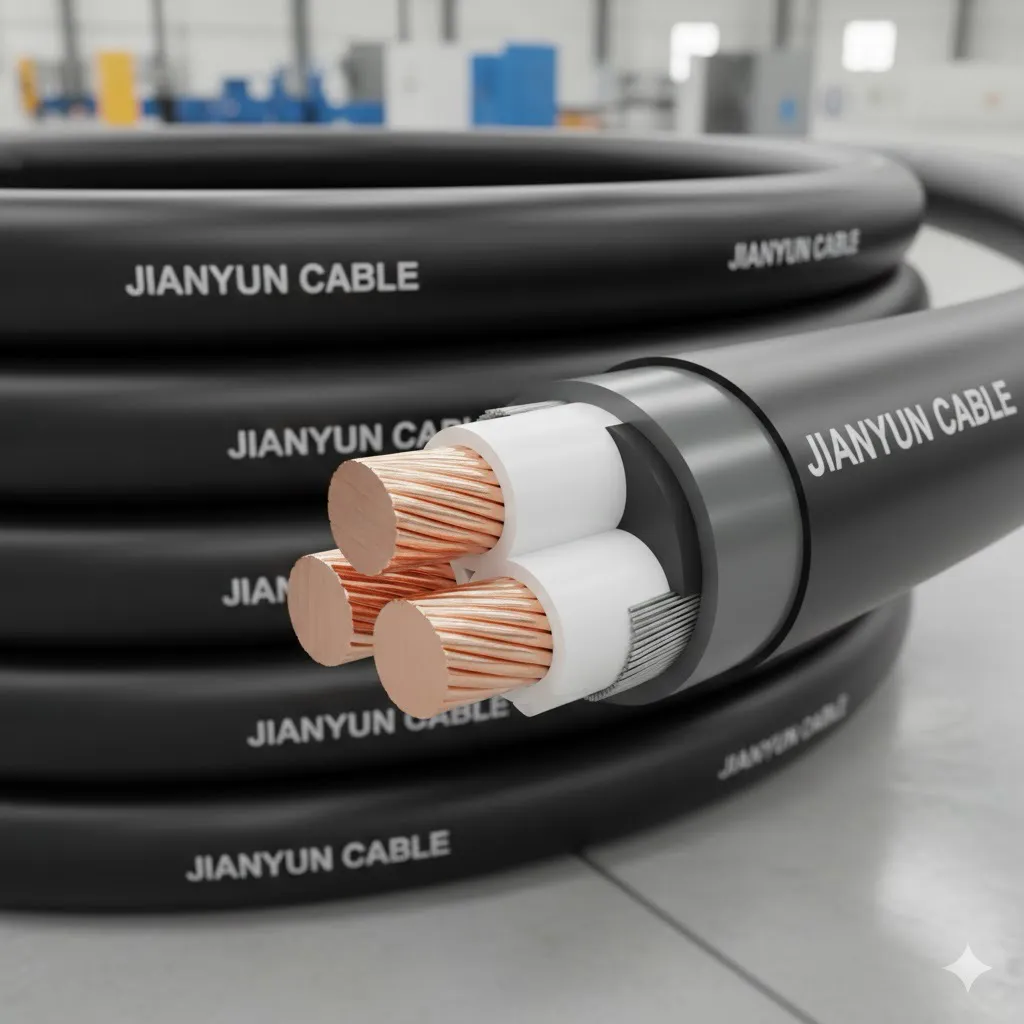

Industrial power cables are expected to operate reliably for 30–50 years or more, yet many fail much earlier due to avoidable mistakes in selection, installation, or maintenance. Downtime, repair costs, safety risks, and production losses make cable longevity a top priority in factories, power plants, mining operations, oil & gas facilities, and heavy manufacturing. This guide shares proven methods to significantly extend the service life of power cables in demanding industrial systems.

Premature cable failure can cause:

Extending cable life by even 10–15 years delivers massive ROI through reduced downtime and maintenance costs.

Understanding failure modes is the first step to prevention:

| Failure Cause | Typical Percentage | Main Impact |

|---|---|---|

| Moisture & Water Ingress | 35–45% | Insulation degradation, corrosion |

| Overheating / Thermal Ageing | 20–30% | Insulation cracking, reduced dielectric strength |

| Mechanical Damage (during install or operation) | 15–25% | Sheath rupture, conductor breakage |

| Overvoltage / Transients | 10–15% | Partial discharge, insulation puncture |

| Chemical / Oil Exposure | 5–15% | Sheath softening, cracking |

Start with the right cable for the application:

Proper installation can add decades to cable life:

Regular maintenance prevents most premature failures:

| Maintenance Task | Recommended Frequency | Purpose |

|---|---|---|

| Visual & thermal inspection | Every 6–12 months | Detect hot spots, damage, leaks |

| Insulation resistance test | Every 1–3 years | Monitor insulation degradation |

| Partial discharge measurement | Every 1–2 years (MV/HV) | Detect early insulation defects |

| Sheath integrity test | Every 2–3 years | Verify outer sheath protection |

| Infrared thermography | Annually | Identify overheating joints/terminations |

Extending the service life of industrial power cables is a combination of smart selection, careful installation, proactive maintenance, and environmental protection. When done correctly, many systems achieve 40–60 years of reliable operation with minimal intervention.

Quick Checklist to Maximize Cable Life:

Need high-quality industrial power cables designed for maximum service life? Contact Henan Province Jianyun Cable Co., Ltd. — your reliable partner for long-lasting, industrial-grade cable solutions.

CE Certification 450/750v H07VVF Flexible Copper PVC Insulated Ac Cable 3*2.5 Mm

low voltage copper conductor PVC insulation underground BV BVR cable for industr

PVC electric wires are one of the most widely used electrical conductors in resi

H07V-U wire is a flexible, low voltage electrical wire commonly used in industri