Time: 2026-01-30 05:34:05 Source: Henan Province Jianyun Cable Co., Ltd.

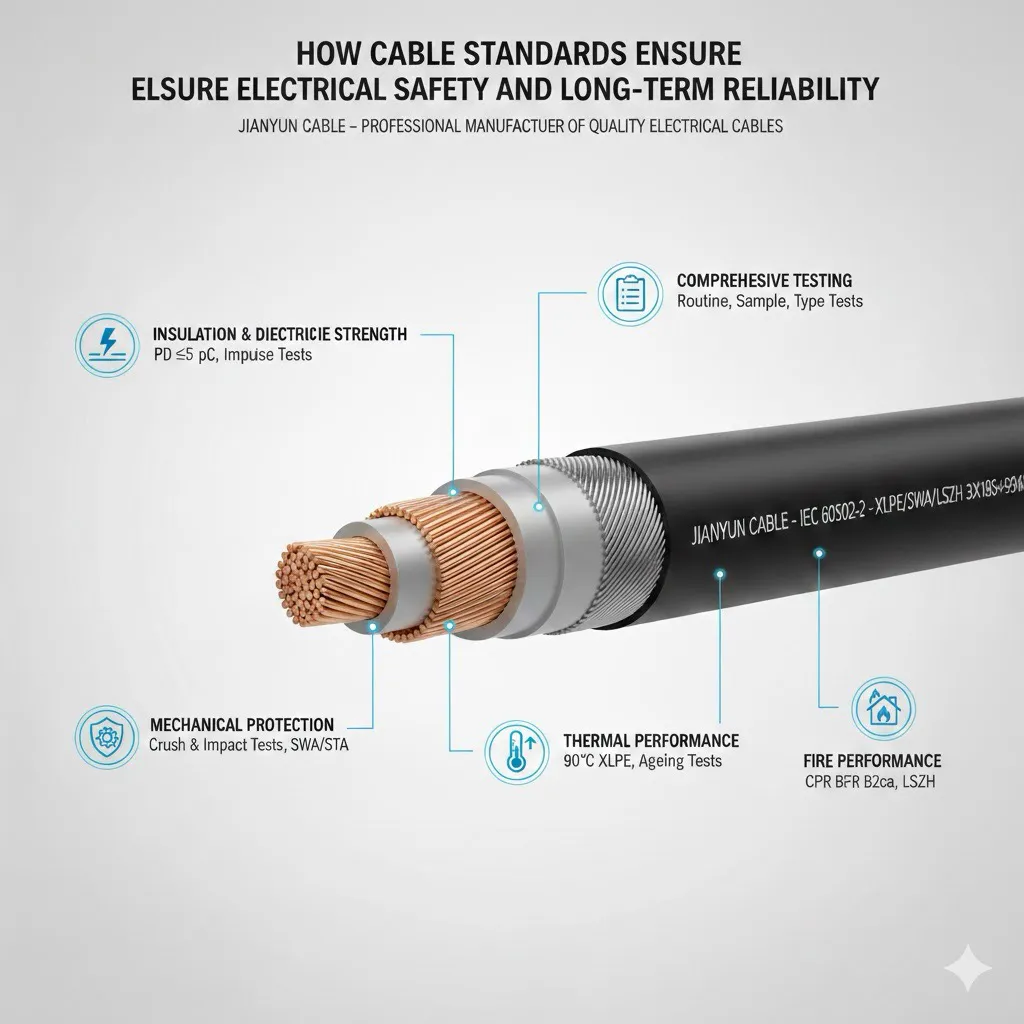

Electrical cables are critical infrastructure components that carry power through buildings, factories, cities, and across continents. A single cable failure can cause fires, blackouts, equipment damage, environmental harm, or loss of life. International and national cable standards (IEC, NEC, UL, BS, AS/NZS, GOST, etc.) exist precisely to eliminate preventable risks and ensure cables perform safely for 30–50 years under real-world conditions. This technical article explains — in depth — how modern cable standards systematically guarantee electrical safety and long-term reliability through material selection, design rules, rigorous testing, and performance verification.

Standards build safety through layered defenses:

Insulation breakdown is the #1 cause of electrical faults.

How Standards Prevent It:

Physical damage during installation or service life causes many failures.

Standards Enforce:

Overheating and material degradation shorten cable life dramatically.

Standards Require:

Fire propagation along cable trays can turn small incidents into disasters.

Standards Mandate:

Standards enforce three-tier testing:

| Safety / Reliability Aspect | IEC 60502 / 60840 | NEC (US) | CPR / EN 50575 (EU) | Key Benefit |

|---|---|---|---|---|

| Insulation Breakdown Prevention | PD ≤5 pC, impulse withstand | Ampacity & insulation tables | N/A (fire focus) | Reduces dielectric faults |

| Mechanical Protection | Crush, impact, armor tests | Article 300.5 burial & protection | N/A | Prevents physical damage |

| Thermal Endurance | 90°C XLPE, ageing tests | Derating tables 310.15 | N/A | Extends service life |

| Fire Safety | IEC 60332 & 60331 | Article 334 & 336 | B2ca–Cca mandatory | Limits fire spread |

| Long-Term Reliability | Type tests + pre-qualification | Listing & marking | Durability classification | 30–50 year design life |

Cable standards are not bureaucratic paperwork — they are battle-tested engineering safeguards that prevent electrical shock, fires, blackouts, and premature failures. By enforcing material purity, insulation strength, mechanical robustness, thermal limits, fire resistance, and exhaustive testing, standards transform ordinary cables into reliable, life-saving infrastructure components. Choosing cables certified to the latest IEC, NEC, UL, BS, or regional standards is the single most effective way to ensure both immediate electrical safety and decades of dependable performance.

Need power cables fully compliant with the latest international safety and reliability standards? Contact Henan Province Jianyun Cable Co., Ltd. – we manufacture certified cables engineered for maximum safety and long-term performance in every application.

CE Certification 450/750v H07VVF Flexible Copper PVC Insulated Ac Cable 3*2.5 Mm

low voltage copper conductor PVC insulation underground BV BVR cable for industr

PVC electric wires are one of the most widely used electrical conductors in resi

H07V-U wire is a flexible, low voltage electrical wire commonly used in industri