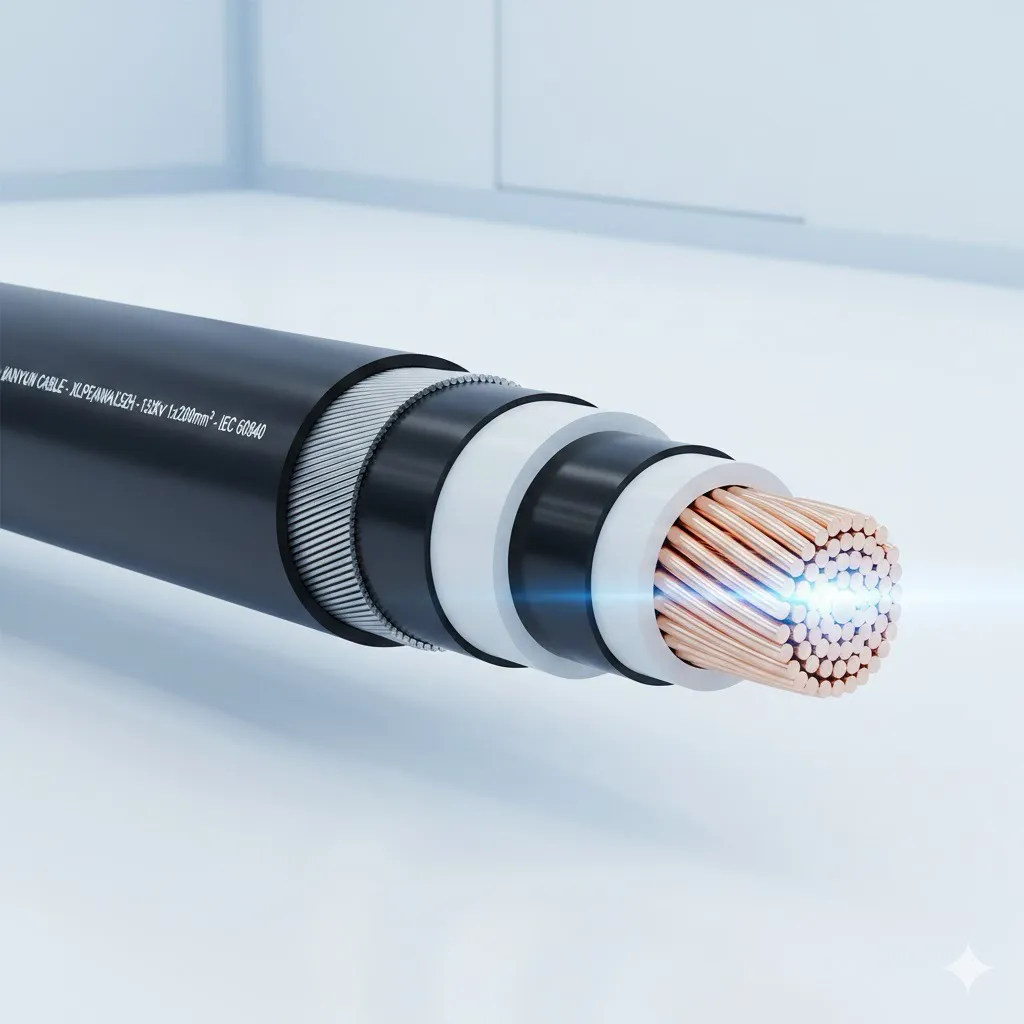

Time: 2026-01-29 11:52:18 Source: Henan Province Jianyun Cable Co., Ltd.

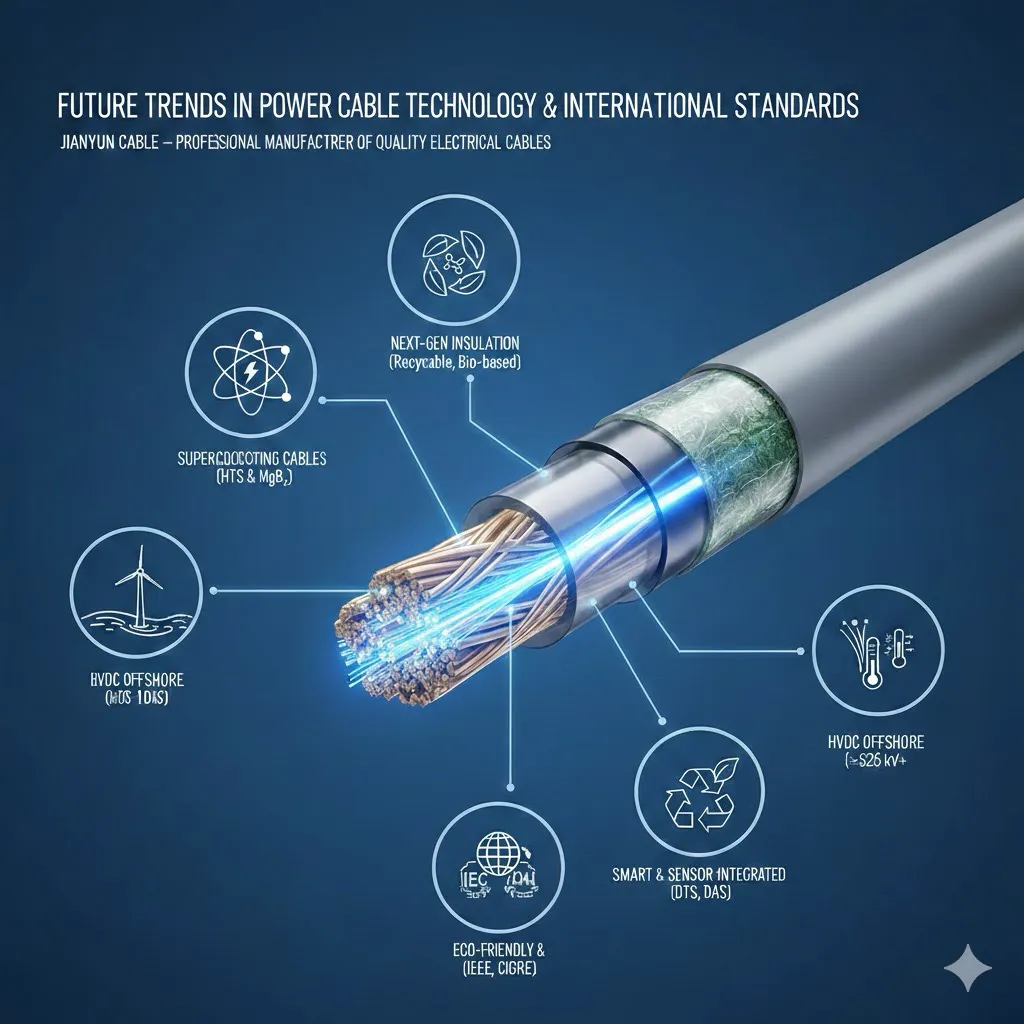

The global energy transition — driven by net-zero targets, massive renewable integration, electrification of transport and industry, and increasing demand for resilient grids — is pushing power cable technology into a new era. Between 2025 and 2035 we will see breakthroughs in superconducting materials, ultra-high-voltage insulation, bio-based polymers, real-time monitoring, and next-generation HVDC systems. At the same time, international standards (IEC, IEEE, CIGRE) are evolving rapidly to qualify these innovations, ensure interoperability, and raise safety & environmental benchmarks. This technical article examines the most promising future trends in power cable technology and how standards are shaping their safe, reliable deployment.

Superconducting cables offer near-zero resistive losses, enabling very high current densities and compact designs.

High-Temperature Superconductors (HTS) (REBCO tapes, 77 K liquid nitrogen cooling):

MgB₂ Superconductors (20–30 K helium or cryocooler):

Standardization Progress: IEC TC 20 WG 19 & CIGRE SC B1 developing qualification guidelines; first test methods expected 2027–2028.

XLPE remains dominant, but innovation focuses on higher temperature, lower losses, and sustainability.

Standardization: IEC TC 20 & CIGRE B1.65 working on test protocols for new insulation classes (2026–2029).

Offshore wind and interconnector projects drive massive demand for ±320 kV to ±525 kV HVDC cables.

Key Trends:

Standardization: IEC 62895 (HVDC extruded cables) & CIGRE TB 852 – new qualification tests for dynamic & long-length cables.

Pressure from EU Green Deal, REACH, and corporate ESG targets accelerates change.

Standardization: IEC TC 20 & EN 50575 updates (2025–2027) expanding circular economy criteria; ISO 14067 carbon footprint labeling for cables.

Digitalization enables real-time condition monitoring.

Standardization: IEC TC 20 & IEEE 1844 – emerging guidelines for integrated sensing; CIGRE B1.89 on smart cable qualification (2026–2028).

Standards bodies are adapting to new technologies:

| Technology | Current State (2025) | Future Outlook (2030–2035) | Key Benefit | Standardization Status |

|---|---|---|---|---|

| HTS Superconducting | Pilots 66–150 kV | Commercial urban & offshore | >95% loss reduction | IEC WG 19 active (2027–2028) |

| 525 kV HVDC XLPE | Commercial offshore wind | ±640 kV & longer lengths | Higher capacity per circuit | IEC 62895 extension ongoing |

| Recyclable TPE Insulation | Early commercial | Mass adoption LV/MV | Circular economy | IEC TC 20 new WG 2026 |

| Smart Cables (DTS/DAS) | Widely used in HV | Standard in MV & dynamic cables | Predictive maintenance | IEEE 1844 & CIGRE B1.89 |

| Bio-based Polymers | Pilot sheaths | Insulation & sheath mainstream | Lower carbon footprint | ISO 14067 & IEC carbon labeling |

The next decade will transform power cable technology from incremental improvements to revolutionary changes: near-zero-loss superconductors, fully recyclable insulation, real-time health monitoring, and ultra-high-capacity HVDC links. International standards bodies (IEC, IEEE, CIGRE) are already laying the groundwork to qualify these innovations safely and ensure global interoperability. Manufacturers and utilities that embrace these trends early will lead the transition to a resilient, sustainable, and highly electrified energy future.

Want to stay ahead with next-generation power cables that align with emerging standards? Contact Henan Province Jianyun Cable Co., Ltd. – we actively participate in standardization and deliver forward-looking solutions for tomorrow’s grids.

CE Certification 450/750v H07VVF Flexible Copper PVC Insulated Ac Cable 3*2.5 Mm

low voltage copper conductor PVC insulation underground BV BVR cable for industr

PVC electric wires are one of the most widely used electrical conductors in resi

H07V-U wire is a flexible, low voltage electrical wire commonly used in industri