Time: 2026-01-29 11:37:28 Source: Henan Province Jianyun Cable Co., Ltd.

By Jianyun Cable – Professional Manufacturer of Quality Electrical Cables

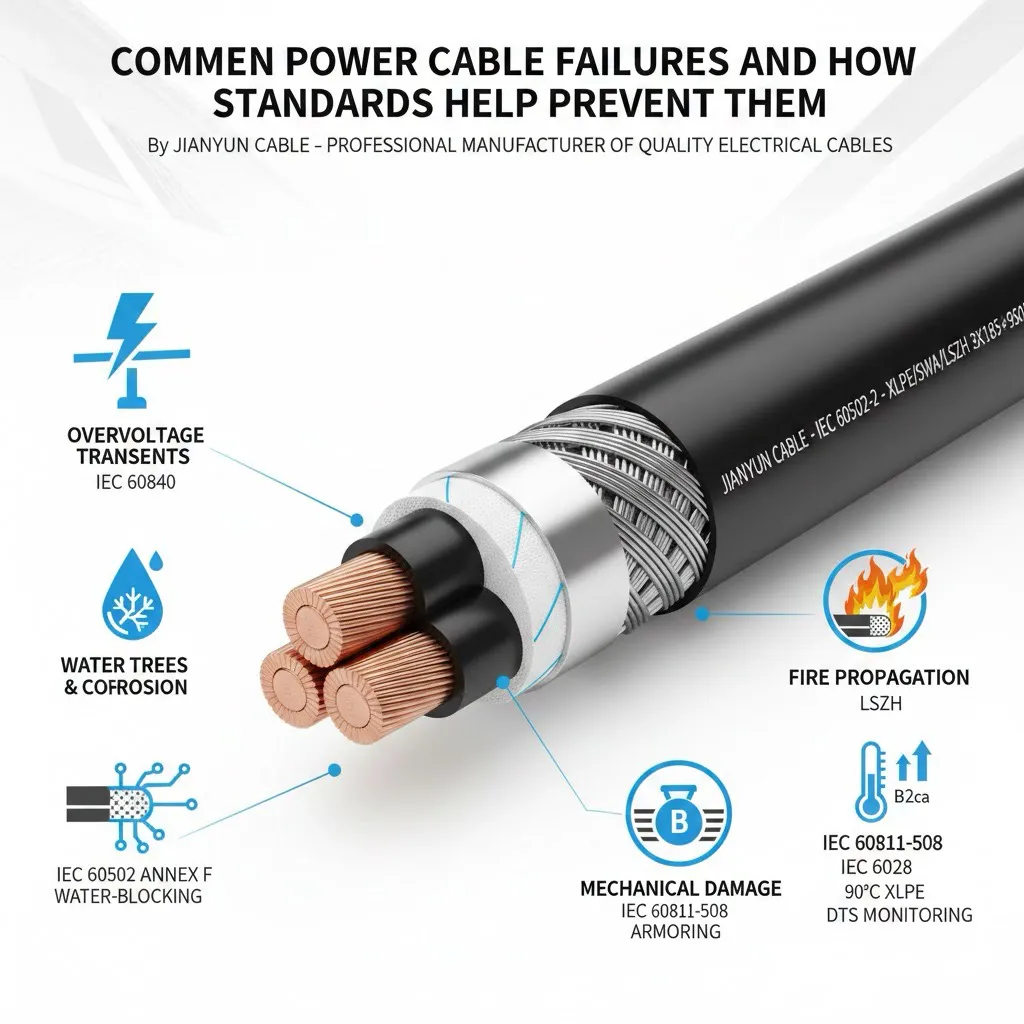

Power cable failures remain one of the leading causes of unplanned outages, fires, equipment damage, and safety incidents in industrial, utility, and infrastructure systems. A single failure can result in millions in downtime costs, environmental damage, or loss of life. Fortunately, modern IEC, NEC, IEEE, and national standards incorporate rigorous design, manufacturing, testing, and installation requirements that dramatically reduce failure probability. This technical article classifies the most common power cable failure modes, explains their root causes, and shows how current standards actively prevent them — providing engineers and asset managers with actionable insights for 2025 and beyond.

Failures can be grouped into five primary categories:

Most frequent in MV/HV cables (60–70% of outages).

Root Causes:

Consequences: Arc flash, short circuit, explosion risk.

Prevention by Standards:

Common in direct-buried and industrial settings.

Root Causes:

Prevention by Standards:

Gradual degradation leading to eventual breakdown.

Root Causes:

Prevention by Standards:

Particularly destructive in underground & submarine cables.

Root Causes:

Prevention by Standards:

Critical in public buildings, tunnels, petrochemical plants.

Root Causes:

Prevention by Standards:

Standards prevent failures through:

| Failure Mode | Primary Causes | Key Preventive Standards | Effectiveness |

|---|---|---|---|

| Insulation Breakdown | Voids, PD, water trees, transients | IEC 60502-2 PD ≤5 pC, IEC 60840 impulse test | Very high (reduced MV failures >70%) |

| Mechanical Damage | Crush, impact, poor bending | IEC 60811-508 crush/impact, NEC burial rules | High with proper armoring |

| Thermal Overload | Overcurrent, poor heat dissipation | IEC 60287 rating, 90°C XLPE | High with monitoring |

| Water Ingress | Sheath damage, poor joints | IEC 60502 water penetration test, blocking tapes | Very high in modern designs |

| Fire Propagation | Flame spread, high smoke | IEC 60332-3, CPR B2ca–Cca, LSZH | High in compliant installations |

Most power cable failures are preventable through proper design, manufacturing, installation, and maintenance guided by IEC, NEC, and related standards. By understanding failure modes and how modern standards address them — from partial discharge limits to fire-resistant LSZH sheaths — asset owners can significantly reduce risk, extend cable life, and improve system reliability. Investing in standards-compliant cables and regular diagnostic testing is one of the highest-ROI decisions in power infrastructure.

Need armored or unarmored power cables engineered to the latest IEC standards with proven failure resistance? Contact Henan Province Jianyun Cable Co., Ltd. – we deliver certified, high-reliability solutions built to last.

CE Certification 450/750v H07VVF Flexible Copper PVC Insulated Ac Cable 3*2.5 Mm

low voltage copper conductor PVC insulation underground BV BVR cable for industr

PVC electric wires are one of the most widely used electrical conductors in resi

H07V-U wire is a flexible, low voltage electrical wire commonly used in industri