Time: 2026-01-30 05:46:51 Source: Henan Province Jianyun Cable Co., Ltd.

Building wires and industrial power cables may look similar at first glance — both carry electricity — but they are engineered for entirely different environments, loads, and safety requirements. Misapplying one for the other can result in overheating, premature failure, code violations, fire hazards, or catastrophic downtime. This technical article provides a detailed comparison of building wires (used in residential and light commercial settings) versus industrial power cables (designed for heavy-duty factory, plant, and infrastructure use), covering construction, materials, standards, performance, and selection criteria to help engineers, contractors, and specifiers make informed decisions.

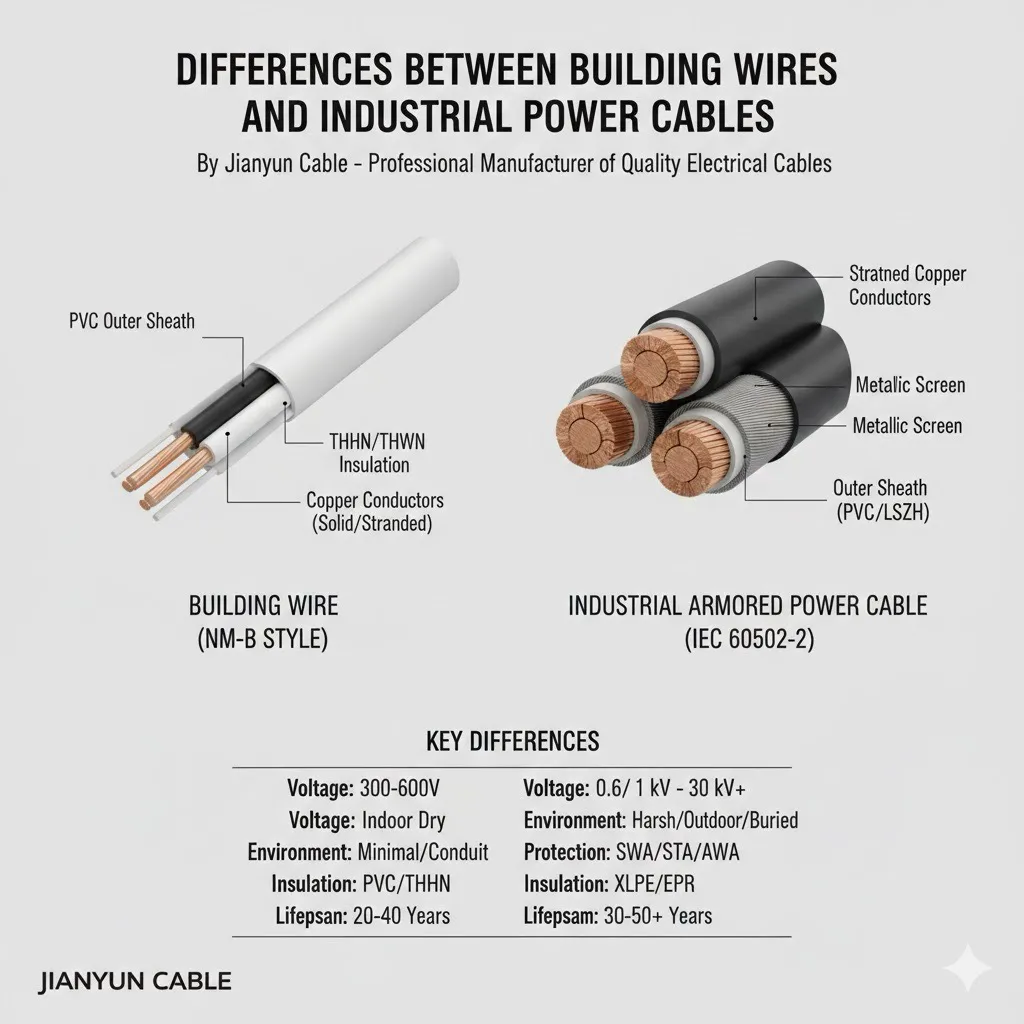

Building Wires: Single or multi-conductor insulated wires (often in non-metallic sheathed assemblies like NM-B / Romex) designed for interior wiring in dry locations — lighting, outlets, small appliances, and branch circuits in homes, offices, and light commercial buildings.

Industrial Power Cables: Robust, multi-conductor assemblies (frequently armored or screened) engineered to transmit higher power loads over longer distances in harsh industrial environments — motors, machinery, transformers, feeders, and distribution in factories, petrochemical plants, mining, and heavy infrastructure.

Building wires are simple and cost-effective; industrial power cables are multi-layered for protection and performance.

Industrial environments demand far greater robustness.

| Parameter | Building Wires | Industrial Power Cables |

|---|---|---|

| Typical Voltage Rating | 300–600 V | 0.6/1 kV to 18/30 kV+ |

| Primary Environment | Dry indoor (walls, ceilings) | Harsh industrial, outdoor, buried |

| Insulation Material | THHN/THWN PVC, NM PVC | XLPE, EPR, high-grade compounds |

| Max Operating Temperature | 60–90°C | 90–105°C (continuous) |

| Mechanical Protection | Conduit or NM sheath only | SWA, STA, AWA, braid armor |

| Partial Discharge Test | Not required | Mandatory (MV/HV) ≤5 pC |

| Typical Conductor Size | 14–4 AWG (2–25 mm²) | 50–630+ mm² |

| Service Life Expectancy | 20–40 years | 30–50+ years |

Building wires and industrial power cables serve fundamentally different roles. Building wires prioritize cost, ease of installation, and flexibility for light-duty indoor use, while industrial power cables are engineered for heavy loads, harsh conditions, long distances, and maximum uptime through robust insulation, screening, armoring, and stringent testing. Understanding these technical differences ensures safe, code-compliant, and reliable electrical systems — whether wiring a home or powering a petrochemical plant.

Need high-performance building wires or industrial power cables that meet the latest safety and reliability standards? Contact Henan Province Jianyun Cable Co., Ltd. – we manufacture certified solutions tailored to every application, from residential to heavy industry.

CE Certification 450/750v H07VVF Flexible Copper PVC Insulated Ac Cable 3*2.5 Mm

low voltage copper conductor PVC insulation underground BV BVR cable for industr

PVC electric wires are one of the most widely used electrical conductors in resi

H07V-U wire is a flexible, low voltage electrical wire commonly used in industri