Time: 2026-02-04 15:30:34 Source: Henan Province Jianyun Cable Co., Ltd.

By Jianyun Cable – Professional Manufacturer of Quality Electrical Cables

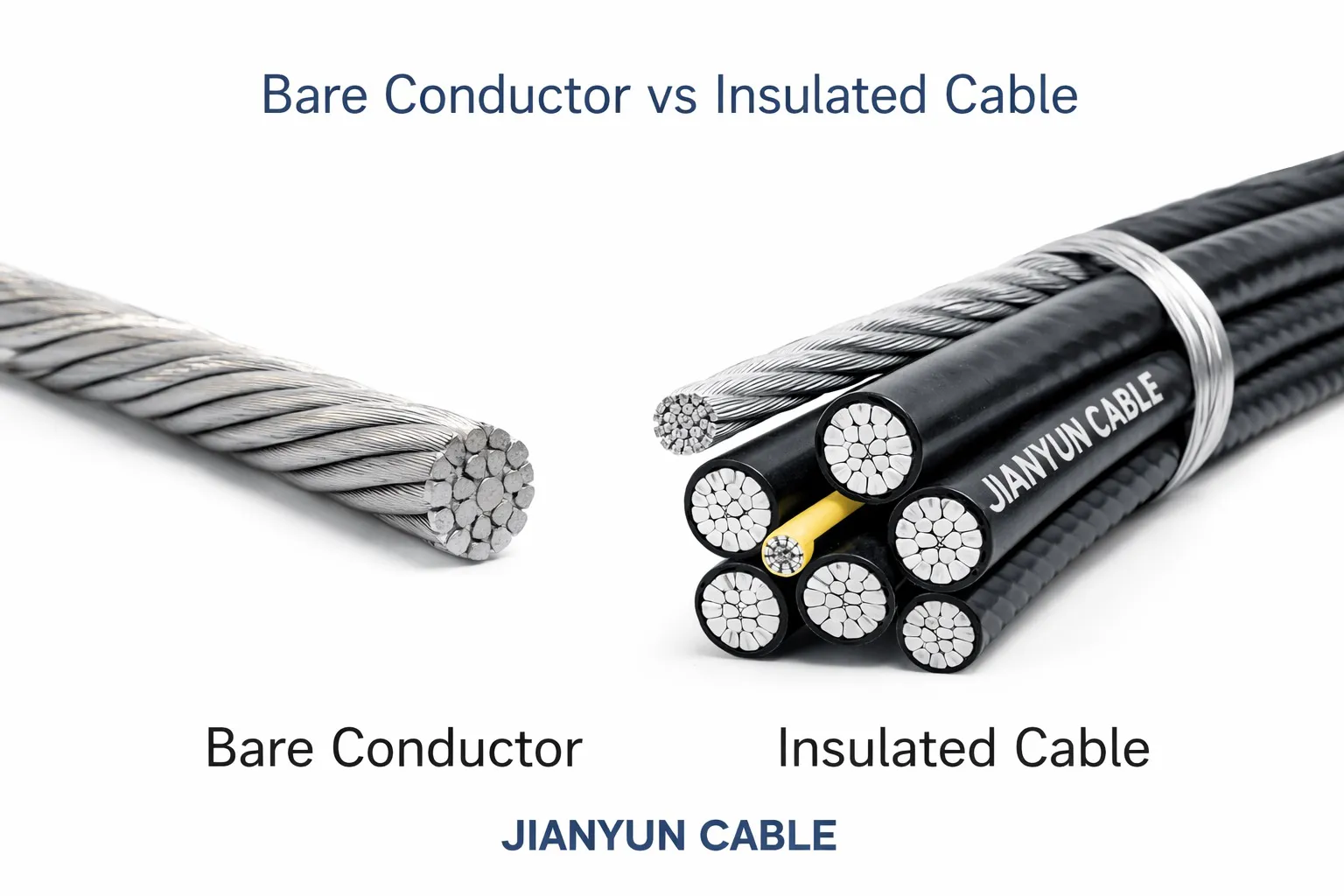

Overhead power lines remain one of the most cost-effective ways to distribute electricity over long distances. Two fundamentally different conductor technologies dominate this field: **bare conductors** (traditional ACSR, AAAC, AAC) and **insulated overhead cables** (commonly known as ABC – Aerial Bundled Cable). Choosing between them significantly affects safety, reliability, maintenance costs, and project economics. This 2025 comparison explains the differences, strengths, weaknesses, and ideal use cases for each type.

For decades, bare conductors were the standard for overhead transmission and distribution lines. Since the 1980s–1990s, insulated bundled cables (ABC) have gained massive popularity — especially for low-voltage and medium-voltage distribution — dramatically improving safety and reliability in many regions. Neither type is universally “better”; the right choice depends on voltage level, environment, budget, safety requirements, and local regulations.

Bare conductors have no outer insulation. The most common types are:

They rely on physical separation and large clearances to prevent phase-to-phase or phase-to-ground faults.

Insulated overhead cables (most commonly ABC – Aerial Bundled Cable) consist of multiple phase conductors individually insulated with XLPE or PE, twisted together around a neutral or messenger conductor (which may be bare or insulated). The insulation eliminates the need for wide spacing between conductors and provides protection against contact.

| Criteria | Bare Conductor (ACSR / AAAC / AAC) | Insulated Cable (ABC) |

|---|---|---|

| Safety – Contact & Short Circuit Risk | High risk (bare live wires) | Very low risk (insulated phases) |

| Tree & Vegetation Interference | Frequent faults & outages | Minimal impact – can touch branches |

| Right-of-Way Requirement | Wide (large clearances needed) | Narrow (can run close to buildings/trees) |

| Installation Cost | Lower material cost | Higher material cost, but often lower overall project cost |

| Maintenance & Outage Frequency | Higher (tree trimming, fault repairs) | Significantly lower |

| Theft Vulnerability | High (easy to cut aluminum) | Much lower (insulated aluminum less attractive) |

| Corona & Radio Interference | More noticeable at higher voltages | Reduced corona effect |

| Typical Voltage Range | All voltages (LV to EHV) | Mainly LV (0.6/1 kV), some MV (up to 36 kV) |

Advantages:

Disadvantages:

Advantages:

Disadvantages:

There is no universal winner — it depends on the project:

For new overhead distribution projects or upgrading aging bare lines, insulated bundled cables (ABC) typically deliver the best balance of safety, reliability, and long-term economy in 2025.

Need high-quality bare conductors or state-of-the-art ABC cables for your overhead line project? Contact Henan Province Jianyun Cable Co., Ltd. — your professional partner for reliable overhead conductor solutions.

CE Certification 450/750v H07VVF Flexible Copper PVC Insulated Ac Cable 3*2.5 Mm

low voltage copper conductor PVC insulation underground BV BVR cable for industr

PVC electric wires are one of the most widely used electrical conductors in resi

H07V-U wire is a flexible, low voltage electrical wire commonly used in industri