Time: 2026-01-05 07:52:51 Source: Henan Province Jianyun Cable Co., Ltd.

Electrical wire and cable form the backbone of modern infrastructure, powering everything from homes to data centers and renewable energy systems. However, their production, use, and disposal carry significant environmental consequences. As demand for electrical wire and cable grows with electrification and digitalization, understanding and mitigating these impacts is crucial for sustainability. This article examines the full lifecycle environmental effects and highlights pathways toward greener electrical wire and cable solutions.

The global electrical wire and cable market exceeds $200 billion, driven by urbanization, renewables, and EVs. Yet, traditional manufacturing relies on resource-intensive processes, generating CO₂ emissions, waste, and pollution. Forward-thinking manufacturers are shifting toward circular economy models to reduce the ecological burden of electrical wire and cable.

The environmental impact spans extraction, production, transportation, installation, use, and disposal. Key concerns include resource depletion, greenhouse gases, toxic chemicals (e.g., halogens), and landfill waste from non-recyclable compounds.

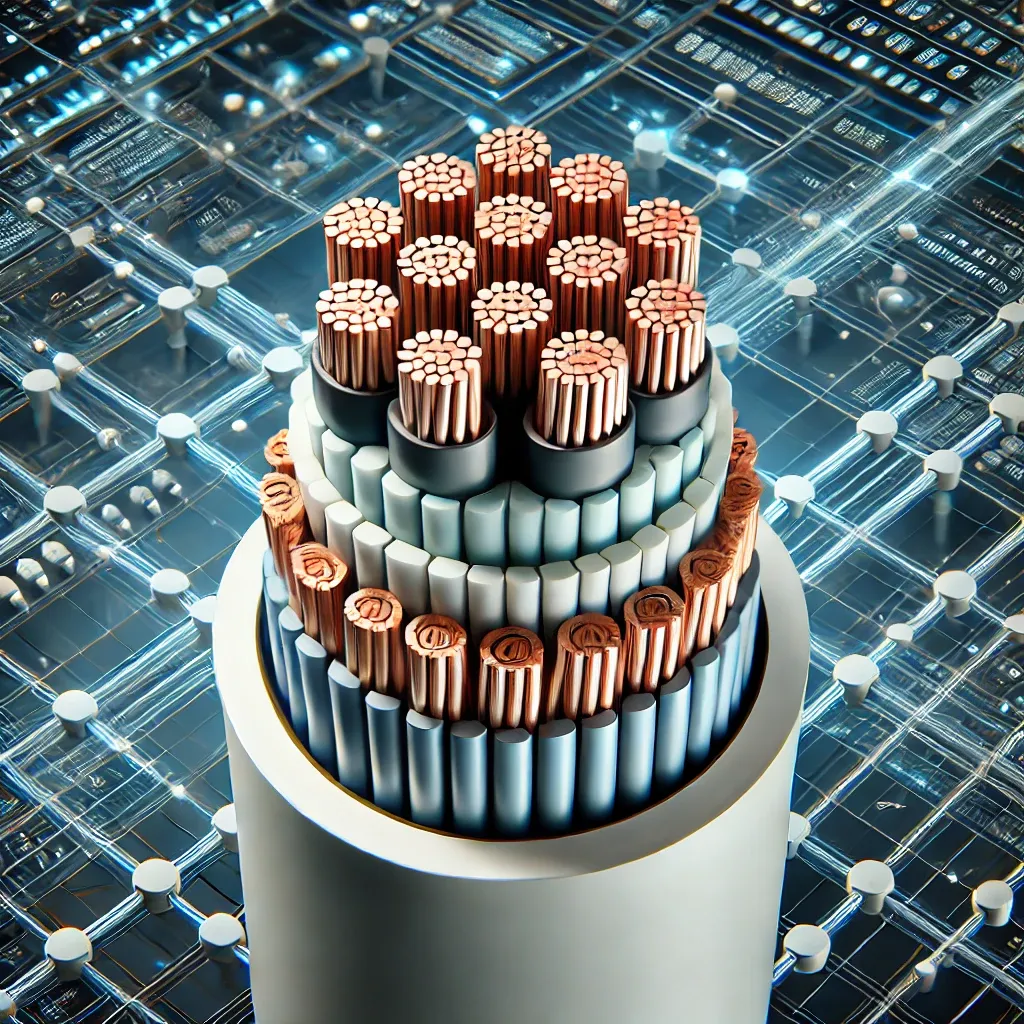

Copper mining consumes vast energy and water, producing tailings and acid drainage. Aluminum refining is electricity-intensive. PVC production involves chlorine and releases dioxins if not controlled. These stages account for up to 60% of a cable's carbon footprint.

Wire drawing, insulation extrusion, and armoring require high heat and power. Traditional processes emit CO₂ and VOCs. Water usage for cooling and emissions from polymer compounding add to the burden.

Poorly designed electrical wire and cable cause resistive losses, wasting electricity equivalent to millions of tons of CO₂ annually. High-quality conductors and insulation minimize these ongoing impacts.

Many cables end in landfills due to mixed materials (metals + plastics). Halogenated insulation releases toxins when burned informally. Recycling rates remain low (20–40% globally), though copper recovery is economically viable.

| Aspect | Traditional Cable | Sustainable Cable |

|---|---|---|

| Materials | Virgin copper, PVC | Recycled metals, LSZH/bio-polymers |

| Carbon Footprint | High (mining + emissions) | 30–70% lower |

| Recyclability | Limited (mixed compounds) | 90%+ recoverable |

| Toxicity | Halogens, dioxin risk | Non-toxic, low smoke |

| Lifespan Impact | Higher energy losses | Optimized efficiency |

The environmental impact of electrical wire and cable is substantial but increasingly addressable through innovation and responsible choices. As regulations tighten and sustainability becomes a priority, greener electrical wire and cable options will dominate, supporting a low-carbon future without compromising performance.

Henan Province Jianyun Cable Co., Ltd. is committed to sustainable electrical wire and cableproduction, using recycled materials and eco-friendly processes to minimize environmental impact while delivering reliable quality.

CE Certification 450/750v H07VVF Flexible Copper PVC Insulated Ac Cable 3*2.5 Mm

low voltage copper conductor PVC insulation underground BV BVR cable for industr

PVC electric wires are one of the most widely used electrical conductors in resi

H07V-U wire is a flexible, low voltage electrical wire commonly used in industri