Time: 2025-12-30 08:07:06 Source: Henan Province Jianyun Cable Co., Ltd.

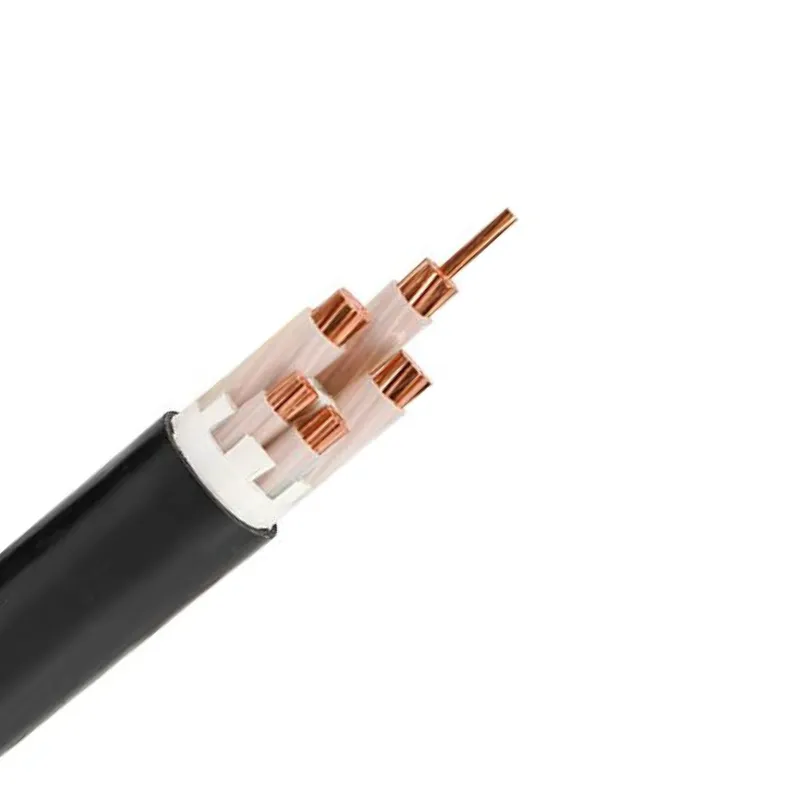

Electrical cables power everything from homes and offices to massive industrial grids and renewable energy projects. Behind every reliable cable is a sophisticated manufacturing process combining precision engineering, advanced materials, and rigorous testing. This guide takes you inside the factory to reveal exactly how electrical cables are manufactured, from raw copper to finished, certified products ready for global markets.

Modern electrical cable production is a highly automated, multi-stage process that transforms basic metals and polymers into safe, durable cables meeting international standards (IEC, UL, VDE). Leading manufacturers like Henan Province Jianyun Cable Co., Ltd. operate state-of-the-art facilities with vertical integration – controlling everything from wire drawing to final packaging – to ensure consistent quality and traceability.

| Step | Process | Key Equipment | Purpose |

|---|---|---|---|

| 1 | Wire Drawing | Multi-die drawing machines | Reduce copper rod from 8mm to fine strands (0.1–4mm) |

| 2 | Annealing | Continuous annealing furnace | Restore ductility and softness after drawing |

| 3 | Stranding/Bunching | High-speed stranding machines | Twist multiple wires into flexible conductors |

| 4 | Insulation Extrusion | Triple-layer extrusion lines | Apply precise insulation (PVC/XLPE) around conductors |

| 5 | Cabling/Laying Up | Drum twisters | Assemble insulated cores with fillers and bedding |

| 6 | Screening & Armoring | Taping and armoring lines | Add shielding and steel wire armor for protection |

| 7 | Outer Sheathing | Extruders | Final protective jacket (PVC/PE/LSZH) |

| 8 | Printing & Coiling | Inkjet printers, coiling machines | Mark specifications and package on drums/reels |

Advanced manufacturers employ Industry 4.0 technologies: real-time monitoring via PLCs, laser diameter gauges for precision (±0.01mm tolerance), X-ray screening detection, and automated guided vehicles for material handling. These ensure consistent quality and high output – up to millions of meters annually.

Every batch undergoes rigorous tests:

Leading producers like Henan Province Jianyun Cable Co., Ltd. prioritize eco-friendly practices: recycled copper, lead-free compounds, energy-efficient machinery, and zero-waste initiatives to reduce environmental impact.

The journey from raw copper rod to finished electrical cable combines science, precision engineering, and decades of expertise. Understanding how electrical cables are manufactured highlights why quality manufacturers deliver safer, longer-lasting products that power the world reliably.

Interested in high-quality electrical cables produced with cutting-edge technology? Contact Henan Province Jianyun Cable Co., Ltd. – a trusted manufacturer delivering excellence worldwide.

CE Certification 450/750v H07VVF Flexible Copper PVC Insulated Ac Cable 3*2.5 Mm

low voltage copper conductor PVC insulation underground BV BVR cable for industr

PVC electric wires are one of the most widely used electrical conductors in resi

H07V-U wire is a flexible, low voltage electrical wire commonly used in industri