Time: 2025-12-30 08:15:42 Source: Henan Province Jianyun Cable Co., Ltd.

In an increasingly electrified world, power cables are the unsung heroes delivering energy safely to homes, offices, and industries. However, not all cables are created equal. Choosing quality power cables is one of the most important decisions for preventing electrical hazards, ensuring long-term reliability, and protecting lives and property. This guide explains why investing in premium cables truly matters.

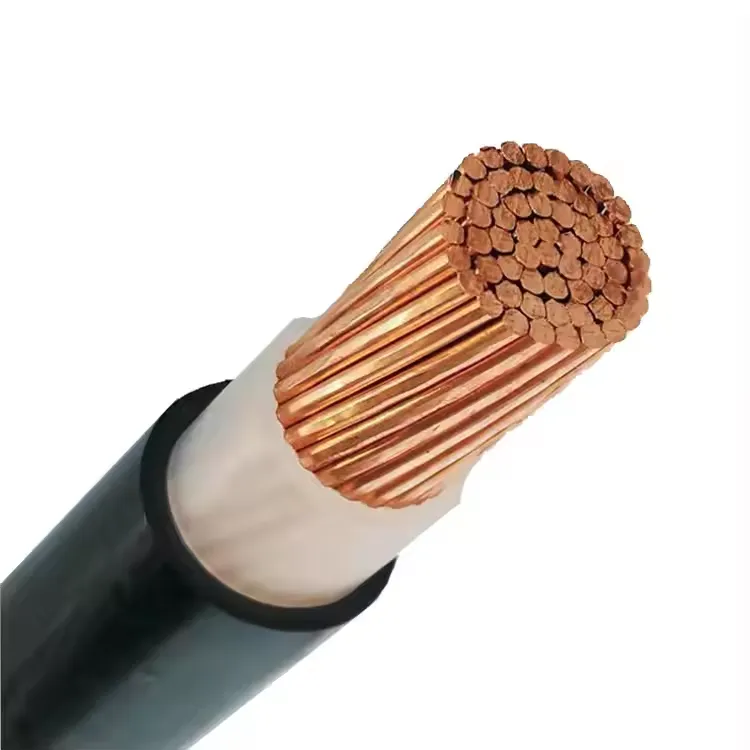

Power cables carry current under constant stress from heat, mechanical forces, moisture, and environmental factors. Substandard materials or manufacturing shortcuts can lead to insulation breakdown, overheating, arcing, or fires. High-quality cables from reputable manufacturers incorporate superior materials, precise engineering, and rigorous testing to maintain integrity even under demanding conditions.

| Aspect | High-Quality Power Cable | Low-Cost Cable |

|---|---|---|

| Conductor Material | 99.99% pure copper/aluminum | Recycled or impure metal |

| Insulation | Premium XLPE/PVC, uniform thickness | Thin, inconsistent coating |

| Testing | Spark, partial discharge, flame tests | Minimal or no third-party verification |

| Lifespan | 30–50 years | 5–15 years |

| Safety Certifications | UL, VDE, CCC, RoHS compliant | Often none or forged |

| Fire Performance | LSZH, CPR Cca or better | High smoke/toxicity |

Electrical fires cause billions in damage annually, with faulty wiring and cables among the top triggers. In many cases, investigations trace failures to undersized conductors, poor insulation, or counterfeit products. Quality cables from established manufacturers dramatically reduce these risks through traceable materials and documented performance.

Quality power cables are not an expense – they are an investment in safety, reliability, and peace of mind. Cutting corners on cables can lead to catastrophic consequences, while choosing proven, certified products protects lives and property for decades. When it comes to electrical safety, there is no substitute for genuine quality.

Henan Province Jianyun Cable Co., Ltd. has been committed to producing high-quality, standard-compliant power cables for over 20 years, serving global projects with safety and performance you can trust. Choose quality – choose safety.

CE Certification 450/750v H07VVF Flexible Copper PVC Insulated Ac Cable 3*2.5 Mm

low voltage copper conductor PVC insulation underground BV BVR cable for industr

PVC electric wires are one of the most widely used electrical conductors in resi

H07V-U wire is a flexible, low voltage electrical wire commonly used in industri