Time: 2025-12-24 07:58:55 Source: Henan Province Jianyun Cable Co., Ltd.

Industrial environments demand robust, reliable electrical cables that withstand harsh conditions, heavy loads, chemicals, moisture, and mechanical stress. From manufacturing plants and oil refineries to automation lines and mining operations, the right industrial electrical cables ensure safety, uptime, and efficiency. This 2025 guide lists the top 10 most widely used electrical cables in industrial applications, ranked by prevalence and versatility.

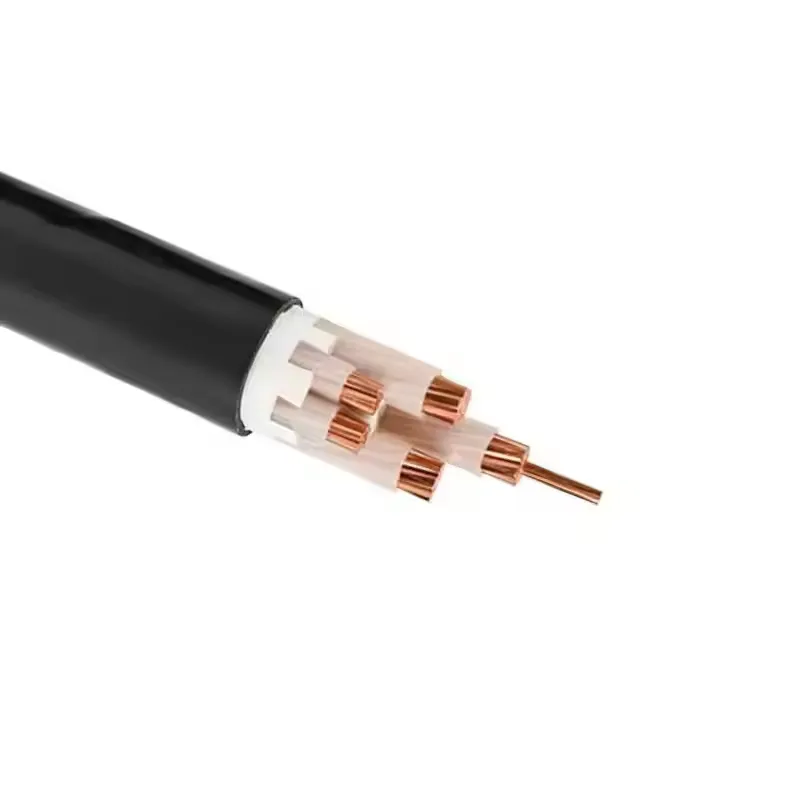

Modern industry relies on specialized electrical cables designed for power distribution, control signals, instrumentation, and variable frequency drives. These cables often feature armoring, shielding, high-temperature insulation, and compliance with strict standards like IEC 60502, IEEE 1580, or UL 1277 to meet hazardous location requirements.

| Rank | Cable Type | Key Features | Typical Voltage | Primary Industry |

|---|---|---|---|---|

| 1 | Armored Power Cables | SWA/STA, XLPE, mechanical protection | 0.6/1 kV | Manufacturing, utilities |

| 2 | VFD Cables | Symmetrical shield, low capacitance | 0.6/1 kV | Automation, motors |

| 3 | Instrumentation Cables | Twisted pairs, foil/braid shield | 300–500 V | Process control, petrochemical |

| 4 | Control Cables | Multi-core, flexible, CY/SY shielded | 300/500 V | Machinery, panels |

| 5 | Tray Cables (TC-ER) | Exposed run, oil/sunlight resistant | 600 V | North American factories |

| 6 | MV Power Cables | XLPE, screened, armored | 6–35 kV | Heavy industry, renewables |

| 7 | High-Temperature Cables | Silicone/PTFE, 150–250°C | 600 V | Steel, glass manufacturing |

These top 10 industrial electrical cables form the foundation of safe and efficient power and signal transmission in demanding environments. Selecting the appropriate cable type minimizes downtime, enhances safety, and supports Industry 4.0 advancements in 2025 and beyond.

Need high-quality industrial electrical cables for your next project? Contact Henan Province Jianyun Cable Co., Ltd. for customized, certified solutions.

CE Certification 450/750v H07VVF Flexible Copper PVC Insulated Ac Cable 3*2.5 Mm

low voltage copper conductor PVC insulation underground BV BVR cable for industr

PVC electric wires are one of the most widely used electrical conductors in resi

H07V-U wire is a flexible, low voltage electrical wire commonly used in industri