Time: 2026-01-08 08:59:25 Source: Henan Province Jianyun Cable Co., Ltd.

Engineers often compare **steel wire armoured cable** (SWA) and steel wire braided (SWB) cables when selecting armoured options. In 2026, understanding the differences between SWB and SWA helps ensure the right choice for safety, performance, and cost in power and control systems.

While both provide protection with steel wires, **steel wire armoured cable** (SWA) focuses on heavy-duty mechanical strength, whereas SWB offers flexibility and EMI shielding. This guide breaks down the practical distinctions.

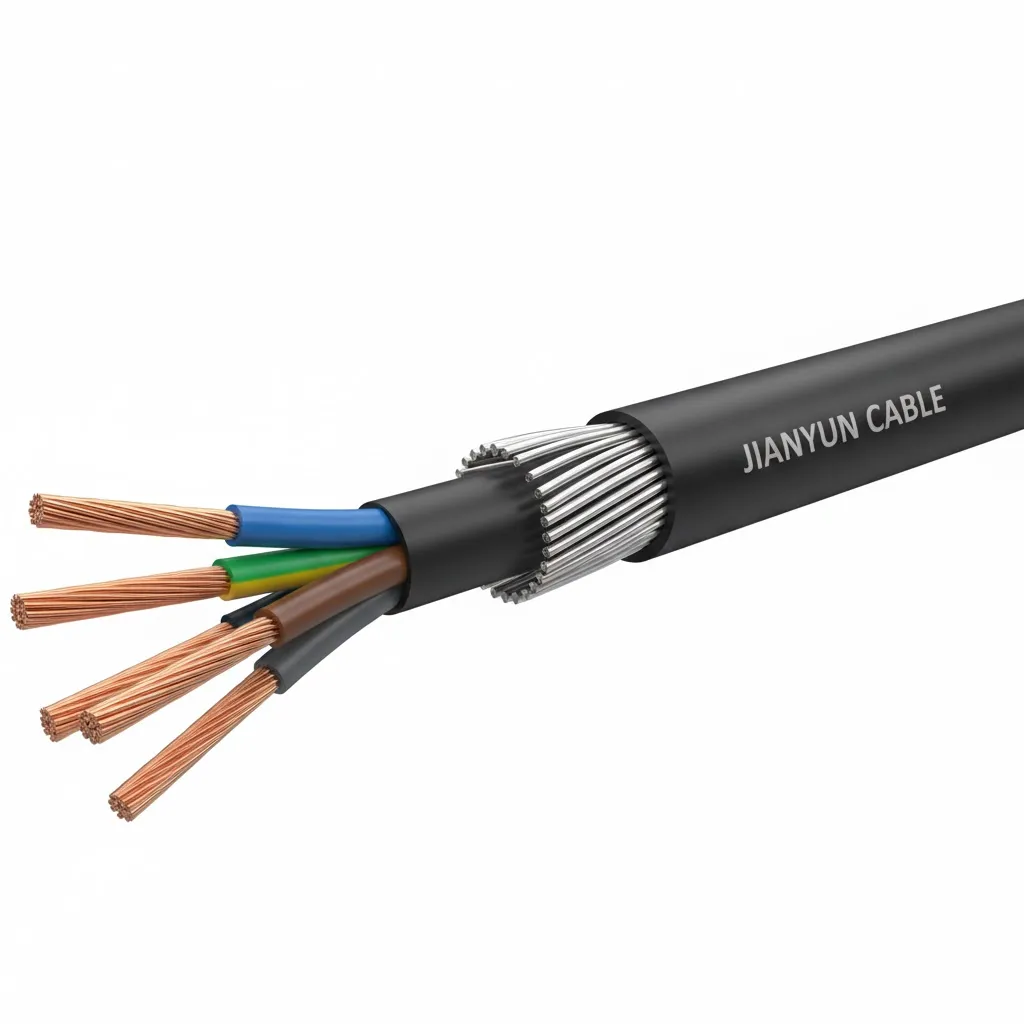

**Steel wire armoured cable** (SWA) is a standard for robust power distribution, featuring helically wound steel wires for superior impact resistance.

SWB, or steel wire braided cable, uses interwoven steel wires for a mesh-like armour, prioritizing flexibility and electromagnetic shielding over raw strength.

Choosing between them depends on environment, movement needs, and interference risks. Both enhance cable durability but suit different scenarios.

**Steel wire armoured cable** (SWA) features galvanized steel wires wound spirally around the cable core, typically achieving 90%+ coverage.

This construction excels in direct burial, underground networks, and areas prone to digging or crushing forces.

SWA is common in mains electricity supply, industrial feeders, and outdoor installations requiring maximum toughness.

SWB cable employs a braided steel wire layer, creating a flexible mesh armour rather than rigid winding.

The braid offers good mechanical protection while allowing easier bending and routing in confined spaces.

SWB also provides effective EMI shielding, making it suitable for control, instrumentation, and vibrating machinery.

SWA uses thicker steel wires helically applied for dense, rigid protection.

SWB applies finer wires in a woven braid pattern, resulting in higher flexibility but slightly lower crush resistance.

Both typically include XLPE or PVC insulation with PVC/LSZH outer sheaths, but braid allows tighter bend radii.

**Steel wire armoured cable** (SWA) delivers superior resistance to impact, compression, and tensile forces – ideal for buried or exposed runs.

SWB provides moderate mechanical protection with excellent EMI shielding due to the braided structure acting as a Faraday cage.

SWA suits static, high-risk areas; SWB fits dynamic or interference-sensitive applications.

Use SWA for underground power, construction sites, and heavy industry where crushing risks are high.

Choose SWB for control panels, instrumentation, robotics, and vibrating equipment needing flexibility and noise reduction.

Hybrid uses combine both in complex systems. More details in our blog on Steel Wire Armoured Cable Uses.

| Feature | SWA Cable | SWB Cable |

|---|---|---|

| Armour Type | Helical wound wires | Braided mesh |

| Mechanical Strength | Excellent (crush/impact) | Good (flexible protection) |

| Flexibility | Limited | High |

| EMI Shielding | Moderate | Excellent |

| Typical Use | Underground power | Control/instrumentation |

Prioritize SWA for static, buried, or high-impact environments needing maximum toughness.

Select SWB where cable movement, tight bends, or electromagnetic interference are concerns.

Consider cost, weight, and standards compliance for the best long-term solution.

Not recommended – SWB offers less crush resistance; use SWA for direct burial.

Yes, the braided structure creates superior shielding against interference.

Limited – rigid armour may fatigue; SWB's flexibility makes it preferable.

Need expert help choosing armoured cables? View our SWA Armoured Power Cables or Steel Wire Braided Cables. Get in touch for tailored recommendations!

CE Certification 450/750v H07VVF Flexible Copper PVC Insulated Ac Cable 3*2.5 Mm

low voltage copper conductor PVC insulation underground BV BVR cable for industr

PVC electric wires are one of the most widely used electrical conductors in resi

H07V-U wire is a flexible, low voltage electrical wire commonly used in industri