Time: 2025-11-24 07:18:17 Source: Henan Province Jianyun Cable Co., Ltd.

Think of electrical cables as the unsung heroes of modern infrastructure – reliable, robust, and rigorously regulated. In Germany, where engineering precision is a national hallmark, these components must pass some of the world's toughest tests under DIN VDE 0100 standards. This guide dives deep into German cable norms, with a focus on the infamous VDE certification. Whether you're an installer, exporter, or engineer, understanding VDE's strict demands ensures safety, compliance, and market access in Europe's powerhouse economy.

DIN VDE 0100, the German implementation of IEC 60364, governs low-voltage installations up to 1000 V AC or 1500 V DC. It covers everything from design and erection to verification and maintenance, emphasizing protection against shock, overcurrent, and fire. Updated regularly – with key revisions in 2022 and ongoing tweaks for 2025 – it aligns with EU directives like the Low Voltage Directive (2014/35/EU) and is legally binding via the German Product Safety Act. Non-compliance can lead to fines, shutdowns, or liability in accidents.

VDE (Verband der Elektrotechnik Elektronik und Informationstechnik) isn't just a stamp – it's a rigorous, independent verification by the VDE Institute, accredited by DAkkS. Founded in 1920, VDE tests over 100,000 products annually against DIN, EN, and IEC norms, focusing on electrical safety, flame retardance, mechanical durability, and environmental resilience. Why so strict? Germany's history of industrial innovation demands zero tolerance for failures; VDE certification reduces fire risks by up to 50% in certified installations.

The process: Factory audits, lab tests (e.g., dielectric strength, abrasion resistance), and ongoing surveillance. It's costlier than self-certification like CE but globally trusted – essential for exports to the EU. In 2025, expect heightened scrutiny on EV integration and sustainability under updated VDE 0604 series.

Cable cross-sections are calculated per VDE 0100-520/529, factoring load, ambient temperature (up to 40°C standard), grouping, and installation method (e.g., in conduit or buried). Voltage drop must not exceed 3% for lighting or 5% for power. Common types use NYM or H07V-U conductors.

| Circuit Type | Cable Size | Breaker Rating | Max Load / Points | Typical Use |

|---|---|---|---|---|

| Lighting | 1.5 mm² | 10–16 A | Max 10 points | Indoor lighting circuits |

| Socket-Outlets (General) | 2.5 mm² | 16 A | Up to 3680 W / 8–12 outlets | Household sockets |

| Radial Socket (High-Power) | 4.0 mm² | 16–20 A | Up to 3680 W / Dedicated | Kitchens, appliances |

| Cooker / Oven | 4.0–6.0 mm² | 32 A | Dedicated circuit | High-power cooking equipment |

| Earth (PE) Conductor | Min 2.5 mm² (copper) | N/A | Full installation | Grounding system |

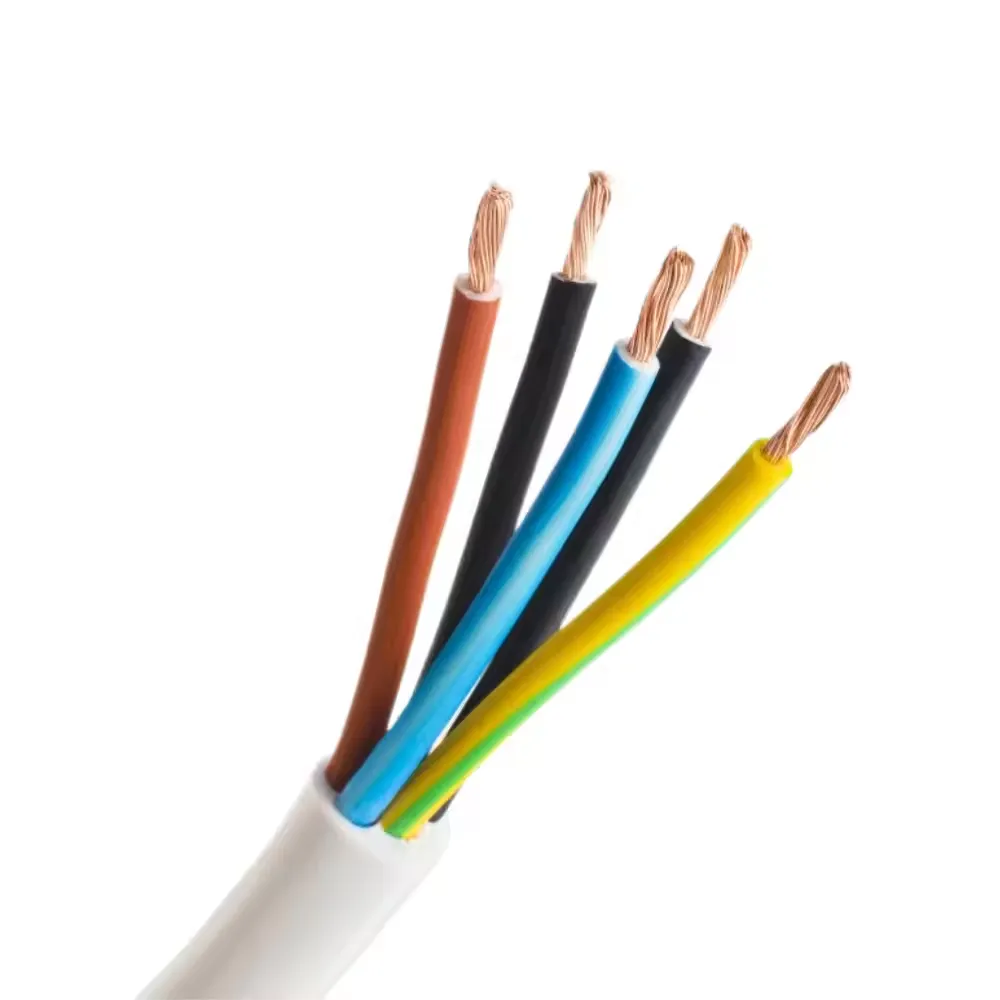

Per DIN VDE 0293-308, Germany follows EU-harmonised colours since 2004 for safety and consistency:

Legacy systems may use older colours (e.g., black for neutral) – always verify and label during retrofits to prevent miswiring hazards.

Germany mandates radial (spur) circuits under VDE 0100-410/430 – no ring mains like in the UK – for straightforward fault isolation and overload protection. Cables must be installed in conduits or trays, with RCDs (30 mA) required for all final circuits since 1984. Key rules:

Under VDE 0100-420 and EU CPR (Construction Products Regulation 305/2011), cables must meet Euroclasses for reaction to fire (EN 13501-6). Permanent installations require at least Eca; higher-risk buildings (e.g., hospitals) demand B2ca or better for limited flame spread and low smoke/acid gas.

VDE tests include bundle burning and smoke density, ensuring minimal hazard in emergencies. Halogen-free (LSZH) cables are preferred for reduced toxicity.

German standards like DIN VDE 0100 and VDE certification embody precision engineering at its finest – strict, yes, but they save lives and drive innovation. In a world of rising electrification, mastering these rules isn't optional; it's essential for safe, efficient systems. Exporters take note: VDE compliance unlocks the €100B+ German market.

Looking for VDE-certified cables tailored to DIN standards? Contact Henan Province Jianyun Cable Co., Ltd. for expert solutions and competitive quotes.

CE Certification 450/750v H07VVF Flexible Copper PVC Insulated Ac Cable 3*2.5 Mm

low voltage copper conductor PVC insulation underground BV BVR cable for industr

PVC electric wires are one of the most widely used electrical conductors in resi

H07V-U wire is a flexible, low voltage electrical wire commonly used in industri