Time: 2026-01-07 06:49:37 Source: Henan Province Jianyun Cable Co., Ltd.

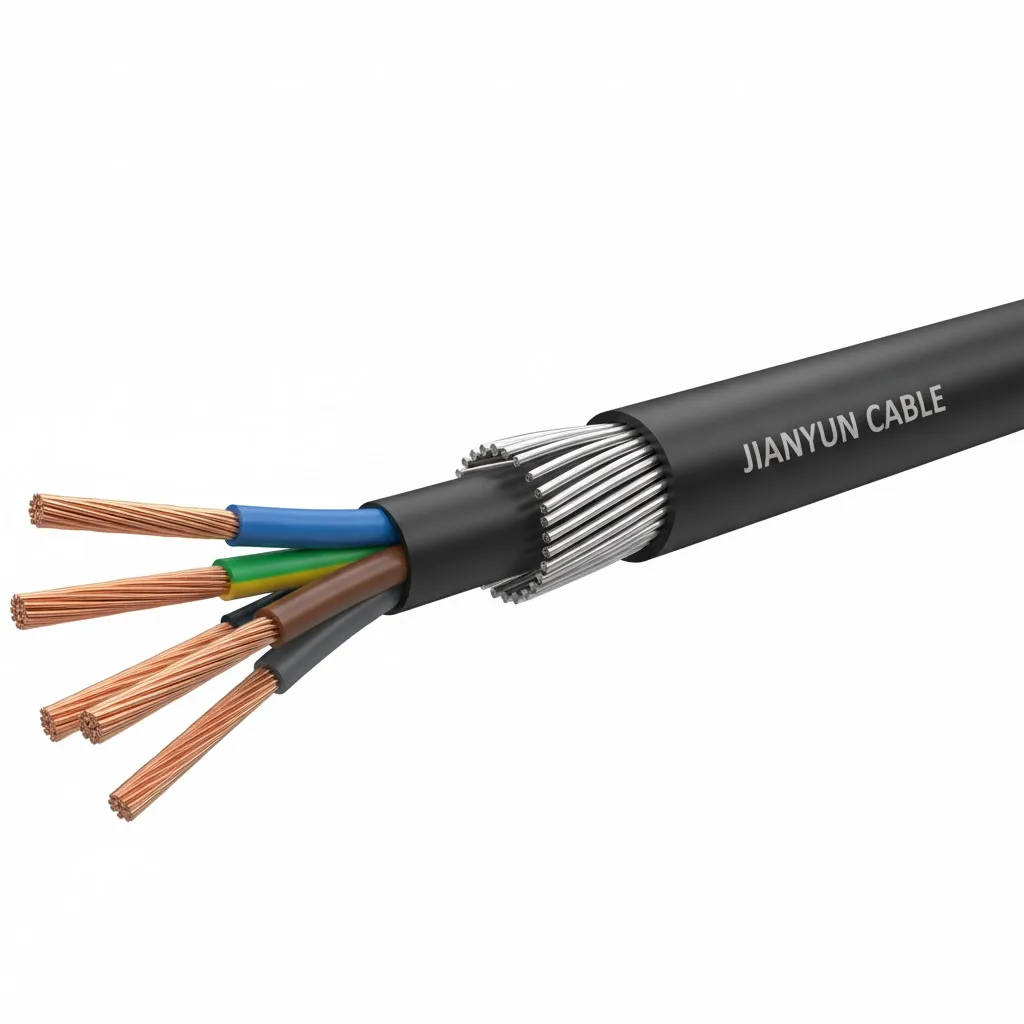

Steel wire armoured cable (SWA) is widely regarded as one of the most durable power cables available. However, no cable is perfect for every situation. Understanding the disadvantages of steel wire armoured cable helps engineers and installers make informed decisions in 2026 projects.

While SWA excels in mechanical protection, its drawbacks in weight, cost, and installation complexity can influence project planning. This guide examines these limitations honestly while maintaining a balanced view.

Steel wire armoured cable provides excellent resistance to physical damage, making it popular for underground and industrial installations. Despite its strengths, several practical disadvantages can affect choice, budget, and long-term performance.

Recognising these limitations early allows better comparison with alternatives like unarmoured XLPE or aluminium wire armoured (AWA) cables. The key is matching the cable to the specific application requirements.

The primary disadvantage of steel wire armoured cable is its significant weight. Galvanized steel armour adds considerable mass compared to unarmoured equivalents.

Larger drums are required for transport, and manual handling becomes more difficult on site. This increases labour requirements and the need for mechanical lifting equipment.

In overhead or vertical installations, the weight can create additional stress on supports and glands, demanding stronger fixing methods.

Steel wire armoured cable typically costs 30–50% more than comparable unarmoured cables due to the steel armour and additional manufacturing steps.

Installation expenses rise from specialist tools (SWA cutters, heavy-duty glands) and longer termination time. Overall project budgets can increase noticeably when extensive runs are needed.

Maintenance or future modifications also cost more because cutting and re-terminating SWA requires skilled labour and specific accessories.

Terminating steel wire armoured cable demands precision. Incorrect armour earthing or poor gland installation can compromise safety and performance.

Specialist SWA glands and shrouds are essential, adding complexity compared to simple unarmoured cable joints. The process is time-consuming and requires training.

Bending radius is larger (typically 8–12 times overall diameter), limiting use in tight spaces or complex routing.

Although galvanized, steel armour can corrode in aggressive soils, coastal areas, or chemical exposure over time.

Corrosion weakens mechanical protection and may affect the armour's ability to serve as circuit protective conductor (CPC). Regular inspection becomes necessary in harsh conditions.

LSZH sheathed versions help, but corrosion remains a long-term consideration for buried steel wire armoured cable.

The rigid steel armour reduces overall cable flexibility, making steel wire armoured cable unsuitable for frequent movement or vibrating machinery.

Tight bends risk damaging insulation or armour wires, leading to potential faults. This limitation restricts use in dynamic applications.

Steel armour is magnetic, causing eddy current heating in single-core AC circuits. This makes steel wire armoured cable unsuitable for single-core high-current installations.

Aluminium wire armoured (AWA) or non-metallic alternatives are preferred to avoid energy loss and overheating.

| Alternative | Key Advantage | Best For |

|---|---|---|

| Unarmoured XLPE | Lighter, cheaper, easier installation | Protected indoor/conduit runs |

| Aluminium Wire Armoured (AWA) | Non-magnetic, lighter | Single-core high-current |

| Conduit-Protected Cable | Flexible routing | Complex indoor layouts |

| LSZH Unarmoured | Low smoke, lighter | Public buildings |

Learn more in our blog post about What is Steel Wire Armoured Cable Used For?

Despite disadvantages, steel wire armoured cable remains the best choice where mechanical protection is critical: direct burial, outdoor exposure, industrial environments, and high-risk areas.

The trade-off between cost/weight and superior durability often favours SWA for long-term reliability and safety.

No – it depends on the environment. For protected indoor runs, lighter unarmoured cables may be more practical and cost-effective.

Yes, in aggressive soils or coastal areas. Proper bedding, warning tape, and periodic inspection help mitigate risks.

Steel armour induces eddy currents and heating. Use AWA or non-metallic alternatives for single-core applications.

Need durable yet balanced cable solutions? Explore our SWA Armoured Power Cables or Aluminium Wire Armoured Cables for lighter alternatives. Contact us for expert advice!

CE Certification 450/750v H07VVF Flexible Copper PVC Insulated Ac Cable 3*2.5 Mm

low voltage copper conductor PVC insulation underground BV BVR cable for industr

PVC electric wires are one of the most widely used electrical conductors in resi

H07V-U wire is a flexible, low voltage electrical wire commonly used in industri