Time: 2025-12-10 12:53:13 Source: Henan Province Jianyun Cable Co., Ltd.

Medium Voltage (MV) power cables are essential for efficient electricity distribution, bridging substations to end-users in industrial, utility, and renewable energy systems. Defined as cables rated from 1 kV to 35 kV, their designation follows standardized nomenclature to ensure clarity in specifications, manufacturing, and installation. Governed primarily by IEC 60502, these designations detail construction, insulation, and performance for safe, reliable operation. This guide explores MV cable designations, helping engineers, installers, and buyers navigate standards for 2025's electrification demands.

MV cables transmit power at voltages above low-voltage systems but below high-voltage transmission lines, typically 6 kV to 30 kV. Their designation encapsulates key attributes like conductor material, insulation type, shielding, and armor, preventing misinterpretation in global projects. With rising solar, wind, and EV infrastructure, understanding these designations is crucial for compliance and longevity.

IEC 60502, from the International Electrotechnical Commission, specifies power cables with extruded insulation for voltages from 1 kV (Um = 1.2 kV) to 30 kV (Um = 36 kV). Part 1 covers 1-3 kV; Part 2 focuses on 6-30 kV MV cables. It outlines construction, dimensions, and tests, harmonized with HD 620 in Europe. Accessories fall under Part 4. These standards ensure cables withstand thermal, electrical, and mechanical stresses in fixed installations like underground ducts or trays.

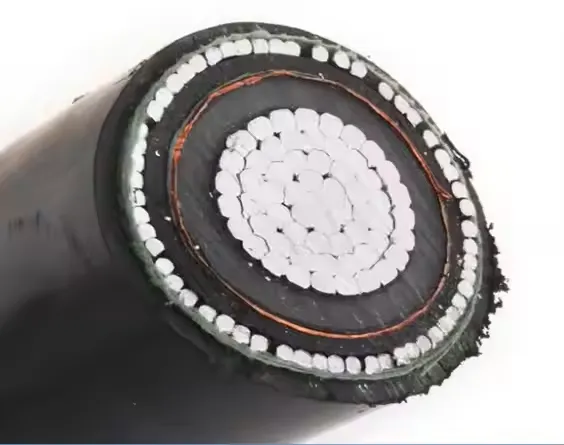

MV cable designations follow a coded format, often starting with insulation type, followed by conductor, screens, armor, and sheath. For example, a typical IEC 60502-2 cable might be denoted as "CU/XLPE/CTS/PVC SWA/PVC" – Copper conductor, XLPE insulation, Copper Tape Screen, PVC inner/Steel Wire Armor/PVC outer sheath. This alphanumeric string aids quick identification, with variations for single-core or multi-core designs.

MV cables feature layered construction for insulation and protection:

This build ensures radial water-blocking and flame retardancy where needed.

| Component | Material Options | Function | Standard Reference |

|---|---|---|---|

| Conductor | Copper (CU) or Aluminum (AL) | Current carrier | IEC 60228 Class 2 |

| Insulation | XLPE, EPR | Voltage isolation | IEC 60502-2 |

| Screens | Semi-conductive + Copper Tape (CTS) | Field control, fault protection | IEC 60502-2 |

| Armor | Steel Wire (SWA), Tape | Mechanical strength | IEC 60502-2 |

| Sheath | PVC, PE, LSZH | Environmental protection | IEC 60502-2 |

Voltage is denoted as U0/U (Um), where U0 is phase-to-earth, U is phase-to-phase, and Um is maximum. Common MV ratings:

| Designation | U0/U (kV) | Um (kV) | Typical Application |

|---|---|---|---|

| 3.6/6 kV | 3.6/6 | 7.2 | Urban distribution |

| 6/10 kV | 6/10 | 12 | Industrial feeders |

| 12/20 kV | 12/20 | 24 | Substation links |

| 18/30 kV | 18/30 | 36 | Long-distance underground |

| 21/35 kV | 21/35 | 40.5 | High-demand utilities |

IEC 60502 mandates routine and type tests: Conductor resistance, partial discharge (<5 pC at 1.5U0), AC voltage withstand (2.5U0 for 30 min), and impulse tests. Water-blocking and flame retardancy (IEC 60332) are optional. Compliance ensures cables operate at 90°C max conductor temperature, with short-circuit ratings up to 250°C.

MV cables suit underground networks, renewables, and industrials. Select based on load, environment (e.g., armored for burial), and standards. For 2025, prioritize LSZH for low-smoke in urban areas and water-blocked for wet zones.

Mastering MV cable designations under IEC 60502 streamlines procurement and installation, ensuring safety and efficiency in power distribution. As global grids evolve, standardized nomenclature remains the foundation for innovation and reliability.

For IEC 60502-compliant MV cables, contact Henan Province Jianyun Cable Co., Ltd. for custom solutions and expert advice.

CE Certification 450/750v H07VVF Flexible Copper PVC Insulated Ac Cable 3*2.5 Mm

low voltage copper conductor PVC insulation underground BV BVR cable for industr

PVC electric wires are one of the most widely used electrical conductors in resi

H07V-U wire is a flexible, low voltage electrical wire commonly used in industri