Time: 2026-01-28 11:18:56 Source: Henan Province Jianyun Cable Co., Ltd.

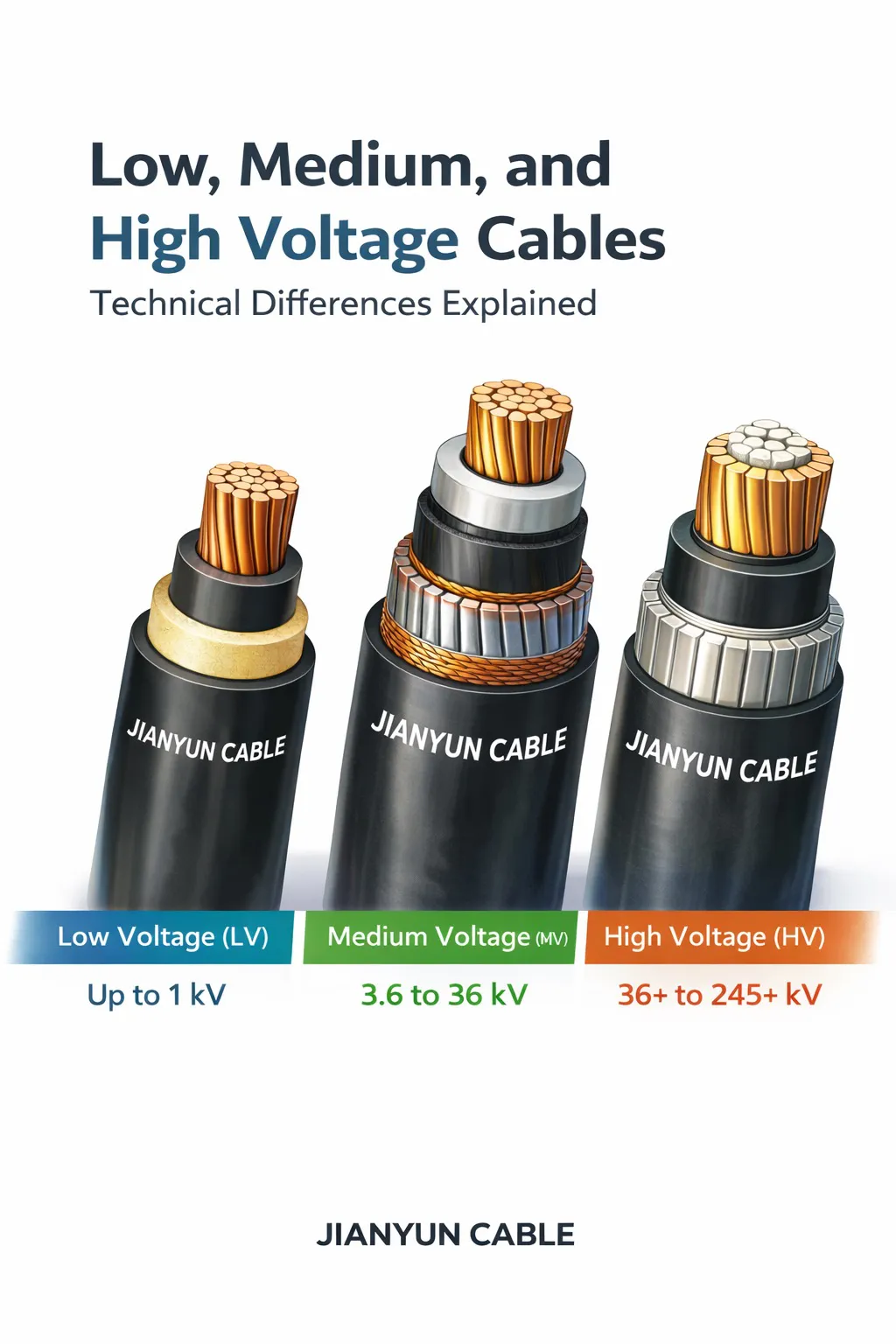

Power cables are classified by their rated voltage to ensure safe and efficient transmission of electrical energy from generation to end-user. The three primary categories — Low Voltage (LV), Medium Voltage (MV), and High Voltage (HV) cables — differ significantly in construction, insulation, testing, and application. Correct classification is critical for safety, cost optimization, and system reliability. This technical guide explains the key differences between low, medium, and high voltage cablesaccording to international standards (IEC, IEEE, ANSI) as of 2025.

International standards (IEC 60038, IEC 60183) define voltage classes as follows:

Note: Extra High Voltage (EHV) starts above 245 kV and Ultra High Voltage (UHV) above 800 kV — these are specialized and less common in industrial contexts.

Construction complexity increases with voltage:

Testing rigor increases dramatically with voltage:

| Parameter | Low Voltage (LV) | Medium Voltage (MV) | High Voltage (HV) |

|---|---|---|---|

| Rated Voltage (U₀/U) | 0.6/1 kV | 3.6/6 kV to 18/30 kV | 36/66 kV to 150/245 kV+ |

| Conductor Screen | Not required | Required (semiconductive) | Required + very uniform |

| Insulation Thickness | 0.6–1.2 mm | 2.5–8 mm | 10–30+ mm |

| Metallic Screen | Optional (concentric) | Mandatory (Cu wires/tape) | Mandatory + high cross-section |

| Partial Discharge Test | Not required | ≤5 pC at 1.5–2U₀ | ≤5 pC at 1.7U₀ + long preconditioning |

| Typical Conductor Size | 1.5–300 mm² | 25–630 mm² | 300–2500 mm² |

| Installation Method | Conduit, tray, direct burial | Underground ducts, direct burial | Underground tunnels, submarine, overhead |

The technical differences between low, medium, and high voltage cables are far more than just voltage ratings — they involve insulation thickness, screening, testing rigor, mechanical design, and long-term reliability. Choosing the correct class ensures safe, efficient power delivery while optimizing cost and minimizing downtime. Understanding these distinctions is essential for engineers, specifiers, and installers working on industrial, utility, or renewable energy projects.

Need expert assistance selecting the right low, medium, or high voltage cables for your application? Contact Henan Province Jianyun Cable Co., Ltd. – we manufacture certified, high-performance cables tailored to the most demanding requirements.

CE Certification 450/750v H07VVF Flexible Copper PVC Insulated Ac Cable 3*2.5 Mm

low voltage copper conductor PVC insulation underground BV BVR cable for industr

PVC electric wires are one of the most widely used electrical conductors in resi

H07V-U wire is a flexible, low voltage electrical wire commonly used in industri