Time: 2025-12-09 06:55:53 Source: Henan Province Jianyun Cable Co., Ltd.

Electric cables are the unsung heroes of modern infrastructure, powering homes, industries, and everything in between. But like all components, they have a finite lifespan, typically ranging from 20 to 50 years depending on type, conditions, and care. Understanding how long cables last – and what shortens their life – is crucial for safety, cost savings, and reliability. In 2025, with rising energy demands and stricter regulations, proactive cable management can prevent failures, reduce downtime, and extend service life. This guide explores average durations, influencing factors, warning signs, and proven tips to maximize longevity.

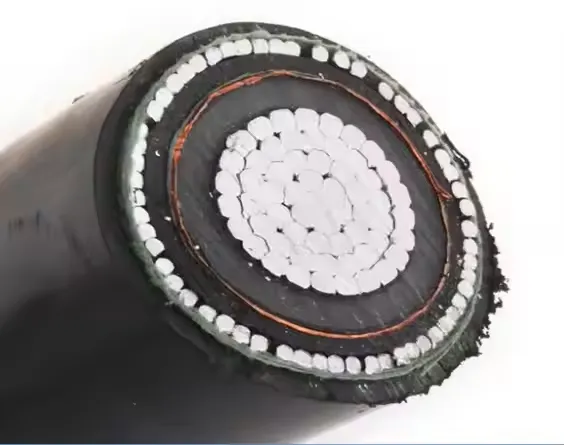

The lifespan of an electric cable refers to the period it can safely and efficiently conduct electricity before degradation compromises performance or safety. While conductors like copper or aluminum endure indefinitely, insulation and sheathing materials are the limiting factors, degrading via thermal, mechanical, or chemical stress. Design life – the manufacturer's expected duration under ideal conditions – serves as a baseline, but real-world variables often dictate actual service life. Proper selection and maintenance can push cables beyond 40 years, avoiding hazards like shorts or fires.

Cable lifespan varies by type, insulation, and application. PVC-insulated cables, common in homes, last 20-30 years under normal loads, while XLPE variants in industrial settings endure 30-50 years. Here's a comparison based on standard conditions (e.g., 70-90°C rating, moderate loads):

| Cable Type | Insulation Material | Average Lifespan (Years) | Typical Application |

|---|---|---|---|

| Household Wiring (NM-B) | PVC | 20-30 | Residential interiors |

| Medium Voltage Power | XLPE | 25-40 | Industrial feeders |

| Armored (SWA) | XLPE/PVC | 30-50 | Underground/outdoor |

| Instrumentation | PE/PVC | 15-25 | Control systems |

| Aerial Bundled (ABC) | XLPE | 30-40 | Overhead distribution |

Several variables accelerate degradation, halving life with every 10°C temperature rise per the Arrhenius rule. Primary culprits include:

Monitor for early warnings to avoid failures:

Replace if degradation exceeds 40% (e.g., retained elongation <60%), or per EICR every 10 years for homes/5 for industry. Proactive testing like partial discharge analysis prevents outages.

Extend service by 20-50% with these practices:

Adhere to IEC 60227 (PVC cables) or IEEE 835 for life estimation. Certifications like UL or BIS ensure quality. In 2025, focus on RoHS for eco-materials and CPR Euroclasses for fire-safe options, which indirectly boost durability via better compounds.

Electric cables last 20-50 years on average, but smart selection, vigilant maintenance, and environmental awareness can push them further. By addressing factors like heat and moisture early, you safeguard systems, cut costs, and enhance safety. Invest in quality today for reliable power tomorrow – your infrastructure deserves it.

Need durable cables? Contact Henan Province Jianyun Cable Co., Ltd. for compliant solutions and quotes.

CE Certification 450/750v H07VVF Flexible Copper PVC Insulated Ac Cable 3*2.5 Mm

low voltage copper conductor PVC insulation underground BV BVR cable for industr

PVC electric wires are one of the most widely used electrical conductors in resi

H07V-U wire is a flexible, low voltage electrical wire commonly used in industri