Time: 2025-12-08 07:53:15 Source: Henan Province Jianyun Cable Co., Ltd.

Industrial installations power the backbone of manufacturing, processing, and heavy machinery operations, where reliability is non-negotiable. Selecting the right electric cable ensures safe power delivery, minimizes downtime, and prevents costly failures. With environments ranging from high-vibration factories to corrosive chemical plants, the wrong cable can lead to overheating, voltage drops, or hazards. This guide outlines essential steps for choosing cables, drawing on industry best practices to optimize performance in 2025's demanding industrial landscape.

In industrial settings, cables must handle high currents, frequent flexing, and harsh conditions while complying with global standards like IEC 60227 and NEC. Poor choices result in 20-30% of electrical faults, per industry reports. Focus on load requirements, environmental resilience, and future-proofing to achieve efficiency and safety.

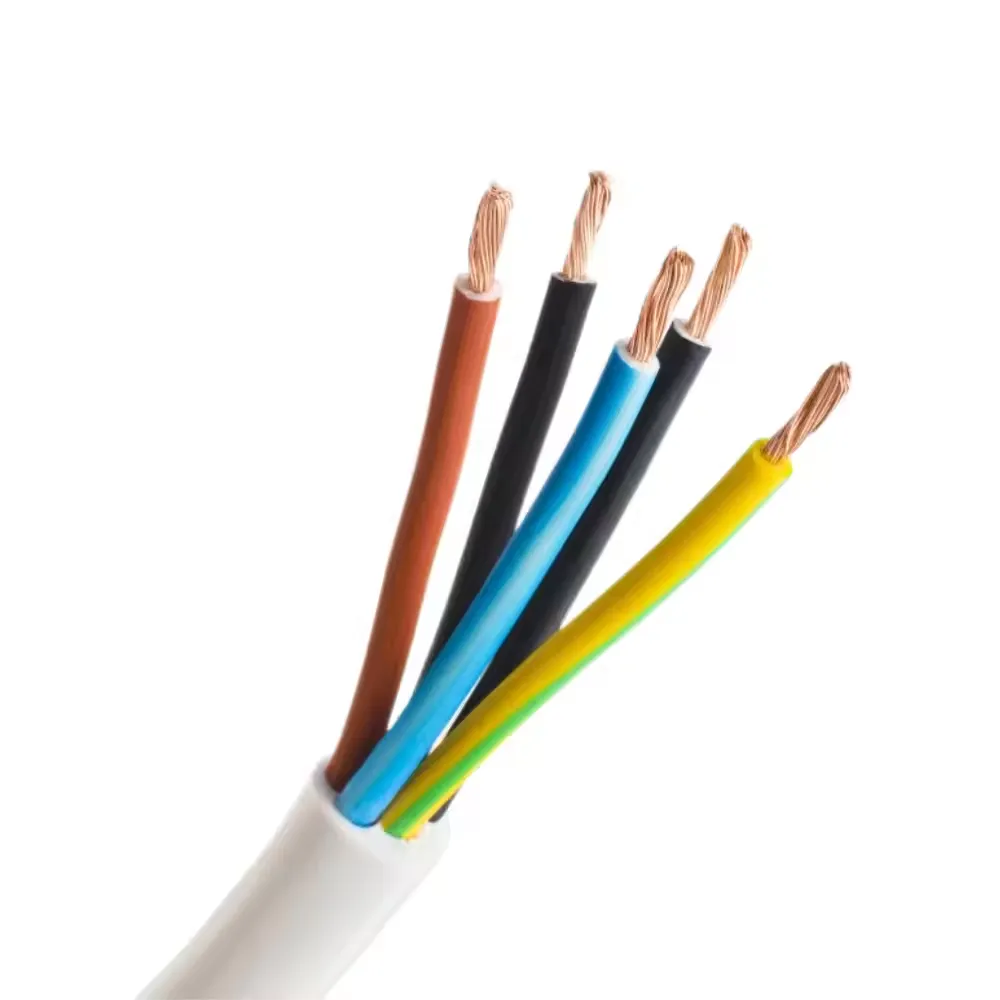

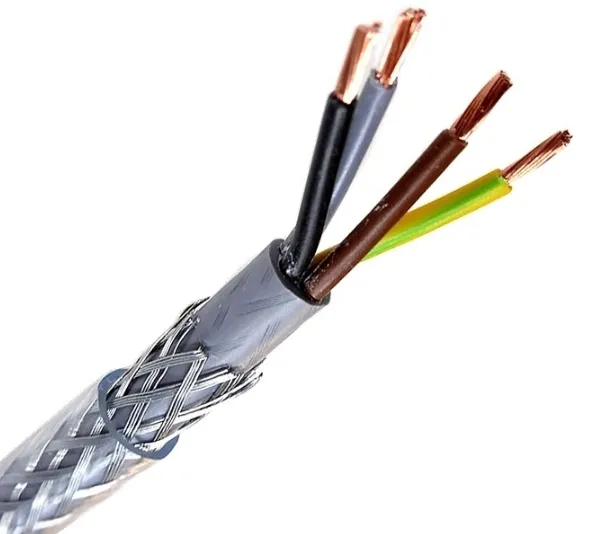

Start with core electrical needs: voltage rating (e.g., 600V for low-voltage systems), current-carrying capacity (ampacity), and conductor material (copper for conductivity, aluminum for cost). Account for voltage drop in long runs – limit to 3-5% by upsizing. Flexibility for moving parts, shielding against EMI from motors, and jacketing for oil/chemical resistance are critical. Budget for certifications like UL or RoHS to ensure longevity.

Industrial cables vary by application. Armored cables (MC/AC) protect against mechanical damage; VFD cables handle variable frequency drives with EMI shielding. Here's a comparison:

| Cable Type | Key Features | Best For | Ampacity Example (90°C) |

|---|---|---|---|

| Armored (MC/AC) | Metal-clad sheath, crush-resistant | Heavy machinery, exposed runs | Up to 400 A (4/0 AWG) |

| VFD Cable | Shielded, low capacitance | Motor drives, inverters | Up to 200 A (2/0 AWG) |

| THHN/THWN | Nylon-coated, wet/dry rated | Conduits, panels | Up to 115 A (3/0 AWG) |

| Teck90 | Armored, direct burial | Outdoor/indoor harsh environments | Up to 300 A (350 kcmil) |

| Instrumentation | Twisted pairs, shielded | Control signals, sensors | Low voltage, 5-10 A |

Size cables using NEC/IEC tables, factoring load (continuous vs. intermittent), temperature (derate 20% at 40°C), and grouping (80% derating for 4+ cables). Tools like ETAP software aid calculations. Example: For a 100A motor at 50m, upsize from 2/0 AWG to 3/0 to limit 3% drop.

Assess hazards: Oil-resistant (OR) jacketing for factories; UV/rodent-proof for outdoors. Bend radius (8x OD min) prevents conductor damage. For flexing applications, choose multi-stranded (Class K). Installation: Allow 24-hour hang time pre-pull to release tension; use strain relief at terminations.

Adhere to NEC Article 310 for sizing, IEC 60364 for global installs. Certifications: UL for US, CE for EU, RoHS for eco-compliance. Verify with third-party tests for EMI shielding and corrosion resistance.

Consult licensed electricians; calculate loads per Article 220. Maintain via periodic inspections for abrasion/heat damage. Future-proof with 20% spare capacity for expansions.

Choosing the right cable transforms industrial risks into reliable performance. By balancing load, environment, and standards, you ensure safety and efficiency. For custom needs, partner with certified suppliers to navigate 2025's evolving regs.

Need industrial cables? Contact Henan Province Jianyun Cable Co., Ltd. for compliant solutions and quotes.

CE Certification 450/750v H07VVF Flexible Copper PVC Insulated Ac Cable 3*2.5 Mm

low voltage copper conductor PVC insulation underground BV BVR cable for industr

PVC electric wires are one of the most widely used electrical conductors in resi

H07V-U wire is a flexible, low voltage electrical wire commonly used in industri