Time: 2025-06-15 16:03:08 Source: Henan Province Jianyun Cable Co., Ltd.

Power cables supply electricity to shipboard systems, including propulsion, lighting, and machinery. Tinned copper conductors with XLPE or EPR insulation and LSHF sheathing are recommended for corrosion resistance and fire safety. These cables are suitable for low, medium, and high-voltage applications on vessels.

Control cables transmit signals for automation and control systems, such as engine monitoring or navigation. TPU or LSHF-jacketed cables with tinned copper braiding provide flexibility, EMI protection, and resistance to saltwater and chemicals.

Instrumentation cables support precise data transmission for sensors and monitoring systems. Shielded cables with tinned copper conductors and FEP or PTFE insulation are ideal for resisting moisture, chemicals, and temperature extremes while minimizing electromagnetic interference.

Communication cables, including coaxial, fiber optic, or Ethernet, enable data transfer for navigation, radar, and communication systems. LSHF-jacketed, UV-resistant cables with watertight designs ensure reliability in wet or exposed conditions.

Specialty cables, such as those for underwater ROVs, towing, or offshore drilling, require tailored designs. Polyurethane or neoprene jackets offer abrasion resistance and flexibility, while aramid or steel armoring enhances tensile strength for demanding applications.

Selecting marine cables involves balancing cost with performance, particularly given the demanding conditions of marine environments. Higher-cost cables often provide enhanced durability and safety features, but the benefits must be weighed against budget constraints.

No definitive evidence proves that expensive cables inherently last longer, but materials like tinned copper and LSHF jackets improve resistance to corrosion and fire, extending lifespan in marine settings. A $5/meter cable lasting three years may be more cost-effective than a $20/meter cable over a decade, but robust construction reduces maintenance costs in harsh conditions.

Allocate 10–15% of the vessel’s electrical system cost to cables, prioritizing mid-range options with LSHF properties and industry certifications. For critical systems, such as propulsion or navigation, invest in higher-quality cables to ensure reliability.

Marketing claims, such as “premium corrosion resistance” or “advanced shielding,” may exaggerate benefits. Without objective testing or compliance with standards like IEC or ABS, such claims are unreliable. Prioritize cables certified by recognized marine authorities to ensure performance.

| Cable Type | Typical Cost Range | Key Features | Applications |

|---|---|---|---|

| Power Cables | $5–$50+/meter | Tinned copper, XLPE/EPR insulation, LSHF jacket; corrosion and fire resistant | Propulsion, lighting, machinery; low to high voltage |

| Control Cables | $10–$100+/meter | TPU/LSHF jacket, tinned copper braiding; EMI protection, flexible | Automation, engine monitoring, navigation systems |

| Instrumentation Cables | $5–$50+/meter | Shielded, FEP/PTFE insulation; moisture and EMI resistant | Sensors, monitoring systems, data transmission |

| Communication Cables | $10–$80+/meter | Coaxial/fiber optic, LSHF, UV-resistant; watertight | Navigation, radar, communication systems |

| Specialty Cables | $15–$150+/meter | Polyurethane/neoprene, armored; abrasion and tensile strength | ROVs, towing, offshore drilling |

Choosing the right cable for marine applications requires prioritizing environmental resistance, safety, and compliance with standards. Power, control, instrumentation, communication, and specialty cables each serve distinct roles, with materials like tinned copper, XLPE, and LSHF jackets ensuring performance in harsh conditions. Budgeting 10–15% of system costs for certified, mid-range cables balances reliability and affordability. Consumers should verify claims against industry standards, avoiding unproven marketing assertions to ensure optimal performance and safety.

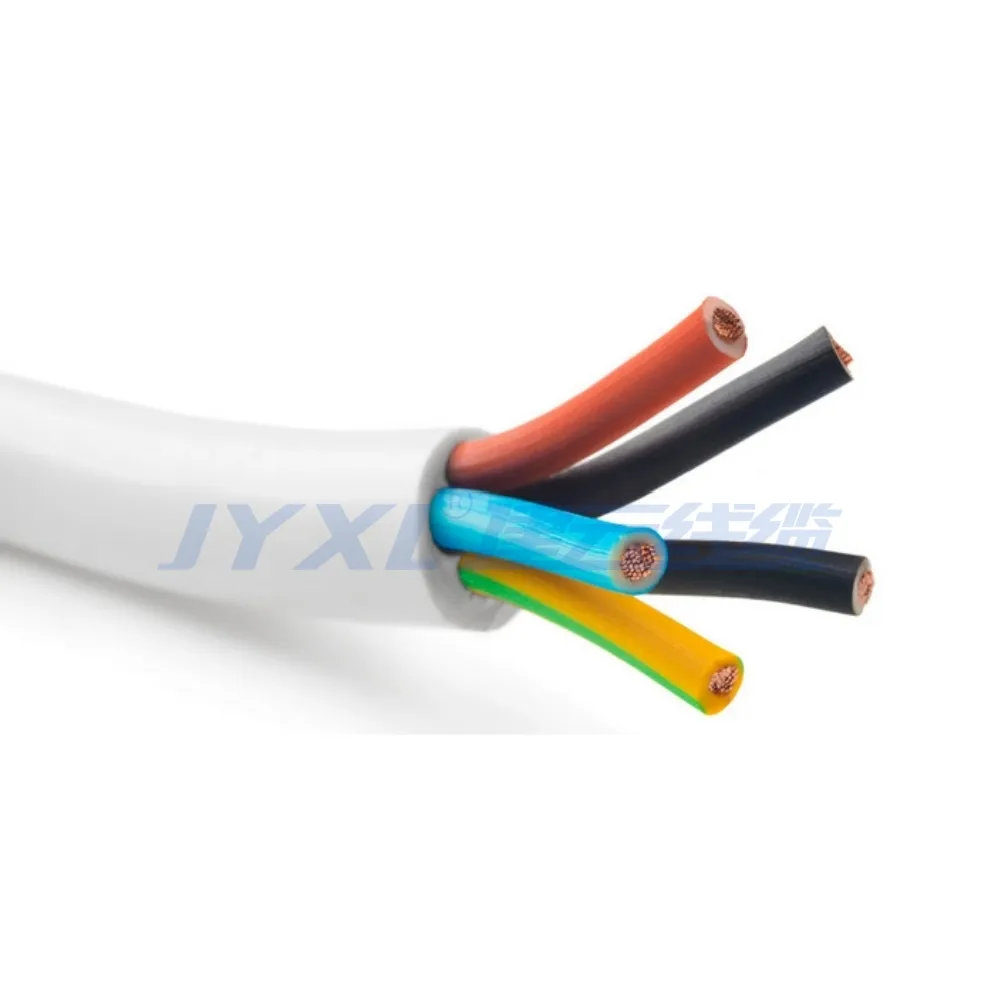

CE Certification 450/750v H07VVF Flexible Copper PVC Insulated Ac Cable 3*2.5 Mm

low voltage copper conductor PVC insulation underground BV BVR cable for industr

PVC electric wires are one of the most widely used electrical conductors in resi

H07V-U wire is a flexible, low voltage electrical wire commonly used in industri