Time: 2025-11-10 06:33:58 Source: Henan Province Jianyun Cable Co., Ltd.

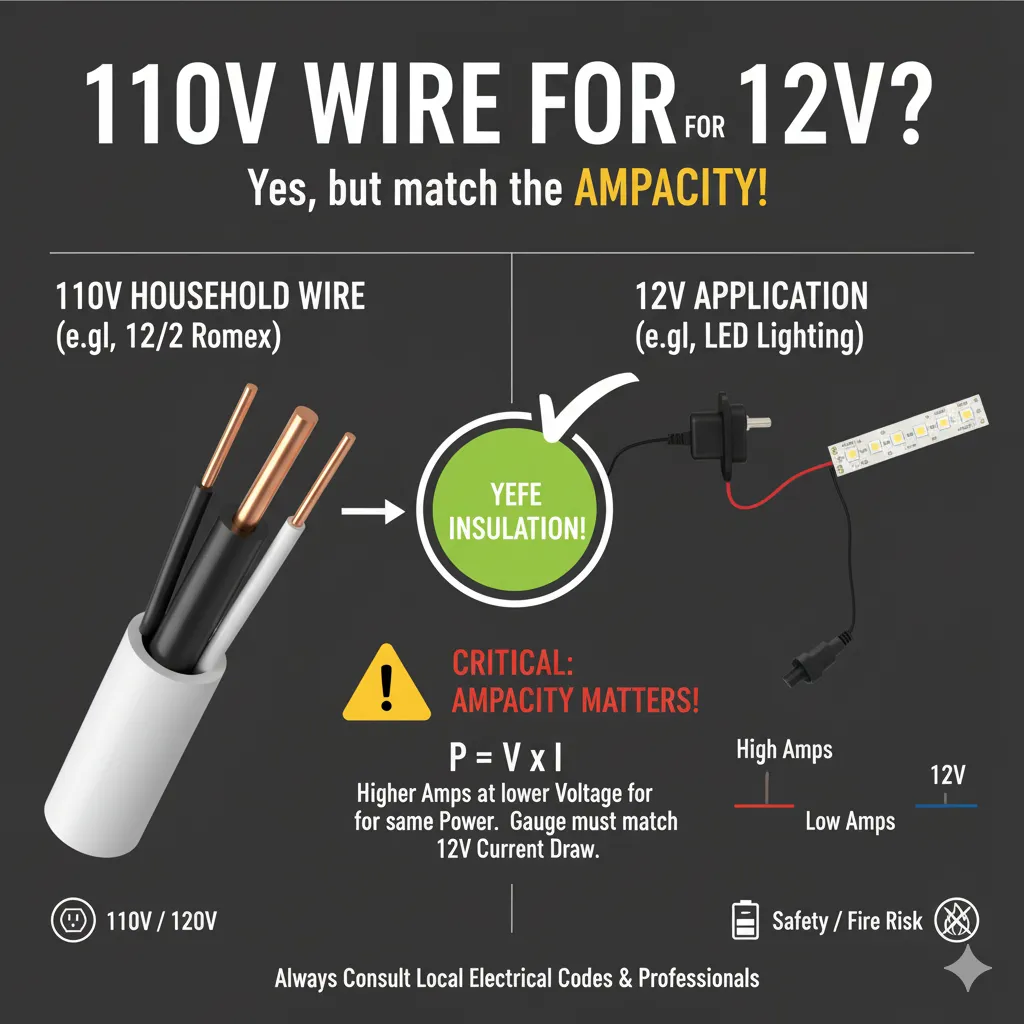

In electrical systems, wires are rated for maximum voltage to ensure insulation integrity and safety. A common question arises regarding the compatibility of wires rated for 110V (or 120V) mains power with low-voltage 12V applications, such as automotive, solar, or landscape lighting systems. This article examines the feasibility, advantages, limitations, and best practices based on established electrical principles and standards as of November 2025.

Wire voltage ratings indicate the maximum potential difference the insulation can withstand without breakdown. A 110V-rated wire (common in North American household wiring) features insulation designed for at least 300V–600V in practice, far exceeding 110V for safety margins. For 12V systems, typically direct current (DC) in batteries or transformers, the voltage is substantially lower, reducing insulation stress significantly.

Yes, a 110V-rated wire can be safely used for 12V applications. The higher voltage rating ensures the insulation is more than adequate, preventing arcing or leakage at low voltages. This practice is common and poses no inherent risk from over-insulation; the primary concern shifts to current-carrying capacity (ampacity) rather than voltage.

| Aspect | Advantages | Disadvantages |

|---|---|---|

| Safety | Excessive insulation margin reduces failure risk | None voltage-related; potential stiffness |

| Cost/Availability | Readily available and often cheaper in bulk | May be over-specified, increasing material use |

| Performance | Handles higher currents if gauge permits | Thicker wires may cause voltage drop over long runs in low-voltage systems due to resistance |

Ensure the wire gauge supports the expected current to minimize heating and voltage drop (critical in 12V systems, where even small drops impact performance). For example, use ampacity charts to select appropriate sizes, and comply with local codes, such as NEC for Class 2 circuits in low-voltage setups.

Avoid if flexibility is crucial (e.g., in tight spaces) or if dedicated low-voltage wire offers cost savings in large projects. Do not mix in the same conduit without proper separation per code, and never use low-voltage wire for 110V applications.

Utilizing 110V-rated wire for 12V systems is not only feasible but often advantageous due to enhanced insulation and availability. Prioritize current rating and code compliance for optimal safety and efficiency. Consultation with a licensed electrician is recommended for specific installations.

CE Certification 450/750v H07VVF Flexible Copper PVC Insulated Ac Cable 3*2.5 Mm

low voltage copper conductor PVC insulation underground BV BVR cable for industr

PVC electric wires are one of the most widely used electrical conductors in resi

H07V-U wire is a flexible, low voltage electrical wire commonly used in industri