Time: 2025-06-09 09:42:07 Source: Henan Province Jianyun Cable Co., Ltd.

Cable ampacity is the maximum continuous current a conductor can carry without exceeding its temperature rating. Exceeding ampacity can damage insulation, cause fires, or reduce the cable’s lifespan.

Ampacity is defined and calculated according to codes such as NEC (USA), IEC 60287, GB/T 12706, and the Neher–McGrath method for steady-state thermal calculations.

For example, NEC Table 310.15(B)(16) lists standard ampacity values for common conductors.

| Conductor Size | Material | Insulation | Installation Type | Ampacity |

|---|---|---|---|---|

| 12 AWG | Copper | PVC (60 °C) | Air | 20 A |

| 10 AWG | Copper | XLPE/THHN (90 °C) | Air | 40 A |

| 6 AWG | Copper | XLPE (90 °C) | Underground | 75 A |

| 2 AWG | Aluminum | XLPE (90 °C) | Conduit | 115 A |

Derating ensures cables operate within safe temperature limits; exceeding temperature limits may halve insulation life per each 10 °C rise.

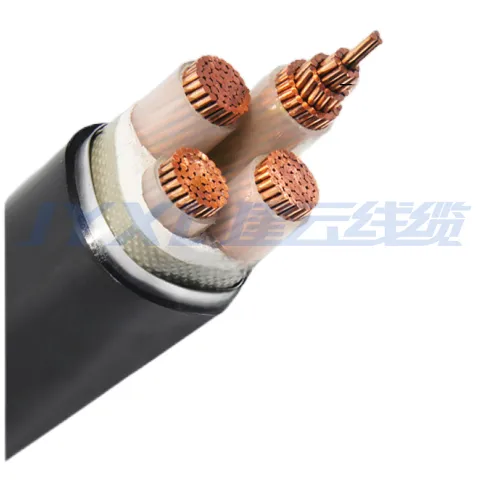

Proper ampacity selection ensures safe, reliable cable performance. Engineers must account for material, environment, insulation, installation, and standards. For specialized applications, consult manufacturer datasheets or technical teams at companies like Jianyun Cable for tailored solutions.

CE Certification 450/750v H07VVF Flexible Copper PVC Insulated Ac Cable 3*2.5 Mm

low voltage copper conductor PVC insulation underground BV BVR cable for industr

PVC electric wires are one of the most widely used electrical conductors in resi

H07V-U wire is a flexible, low voltage electrical wire commonly used in industri