Time: 2025-12-17 10:59:51 Source: Henan Province Jianyun Cable Co., Ltd.

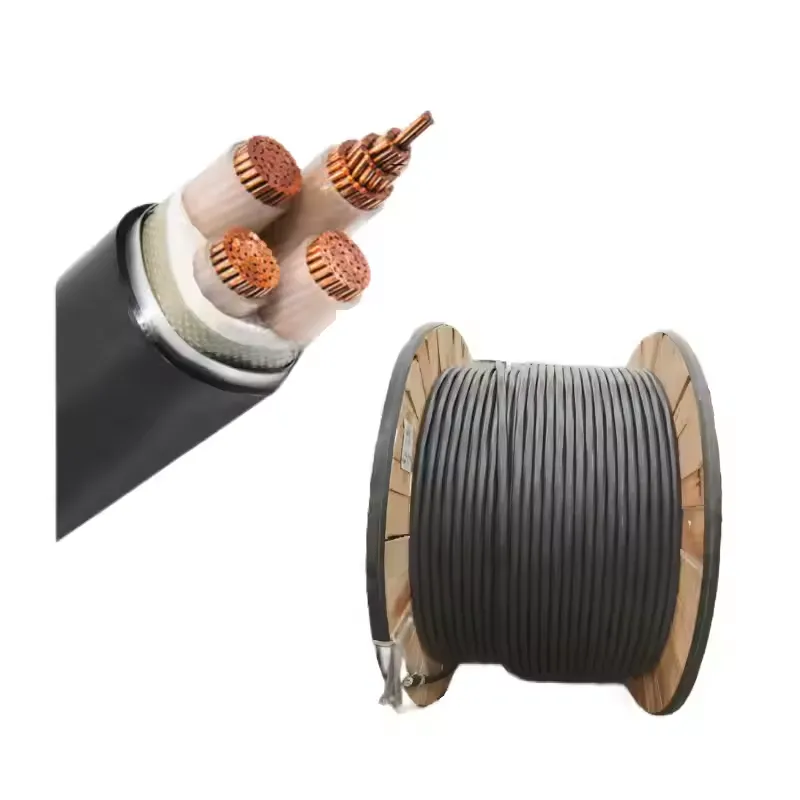

Cross-linked polyethylene (XLPE) is the dominant insulation material for medium- and high-voltage power cables due to its excellent electrical properties, thermal resistance, and mechanical strength. To verify proper cross-linking—essential for thermoset performance—the Hot Set Test is a critical quality control measure. Defined in IEC 60811-507, this test evaluates the degree of cross-linking by measuring elongation and permanent deformation under heat and load. In 2025, as XLPE remains key for renewable energy grids and underground distribution, understanding the Hot Set Test ensures reliable cable manufacturing and long-term performance.

XLPE insulation is created by cross-linking polyethylene molecules through peroxide, silane, or irradiation processes, transforming thermoplastic PE into a thermoset material capable of operating at 90°C continuously (up to 250°C short-circuit). Incomplete cross-linking leads to melting or excessive deformation under load, risking insulation failure. The Hot Set Test, along with gel content analysis, confirms adequate cross-linking during production and type approval.

The test assesses the thermosetting nature of XLPE by subjecting dumbbell-shaped samples to elevated temperature and mechanical stress. It measures maximum elongation under load (indicating cross-link density) and permanent set after cooling (residual deformation). High cross-linking restricts molecular movement, resulting in low elongation and set values.

IEC 60811-507 (part of the 60811 series for insulating and sheathing materials) specifies the Hot Set Test for cross-linked compounds. It replaced older methods and aligns with cable standards like IEC 60502 (MV power cables). Equivalent standards include BS EN 60811-507 and ASTM D2765 (gel content alternative).

| Parameter | Typical Limit (IEC 60502 / Most Specs) | Stricter Limits (Some Manufacturers) | Indication |

|---|---|---|---|

| Maximum Elongation Under Load | ≤ 175% | ≤ 100-150% | Degree of cross-linking |

| Permanent Set After Cooling | ≤ 15% | ≤ 5-10% | Elastic recovery / thermoset quality |

| Test Temperature | 200°C | 200°C or 250°C (high-grade) | Thermal endurance simulation |

| Stress Applied | 0.20 MPa (20 N/cm²) | Same | Mechanical load simulation |

Adequate cross-linking ensures XLPE withstands operating temperatures without softening or flowing, preventing voids, treeing, or breakdown. Passing the Hot Set Test correlates with long-term reliability—cables with low values exhibit better aging resistance and higher short-circuit ratings. It is mandatory for type approval and routine quality control in reputable manufacturing.

The test is sensitive to sample preparation and oven uniformity; it does not directly measure gel fraction. Complementary tests include gel content (IEC 60811-506, ≥70-80% typical), thermal aging, and partial discharge. Together, they provide comprehensive validation of XLPE insulation.

The Hot Set Test remains a cornerstone of XLPE cable quality assurance, offering a simple yet effective measure of cross-linking integrity. In 2025, as grids demand higher performance from XLPE-insulated cables, strict adherence to IEC 60811-507 ensures safety, durability, and efficiency. Manufacturers and specifiers who prioritize low elongation and set values invest in decades of reliable power distribution.

For XLPE cables consistently passing rigorous Hot Set and other tests, contact Henan Province Jianyun Cable Co., Ltd. for certified products and technical support.

CE Certification 450/750v H07VVF Flexible Copper PVC Insulated Ac Cable 3*2.5 Mm

low voltage copper conductor PVC insulation underground BV BVR cable for industr

PVC electric wires are one of the most widely used electrical conductors in resi

H07V-U wire is a flexible, low voltage electrical wire commonly used in industri