Time: 2025-07-31 08:14:55 Source: Henan Province Jianyun Cable Co., Ltd.

Rubber cables are widely used in industrial applications due to their durability, flexibility, and resistance to harsh environmental conditions such as oil, ultraviolet (UV) radiation, and mechanical stress. These cables are designed to deliver reliable power and signal transmission in demanding settings, including factories, construction sites, and outdoor installations. This guide provides a comprehensive overview of rubber cables, focusing on their oil resistance, UV resistance, and flexibility, along with selection criteria and practical considerations, presented in a formal and structured manner.

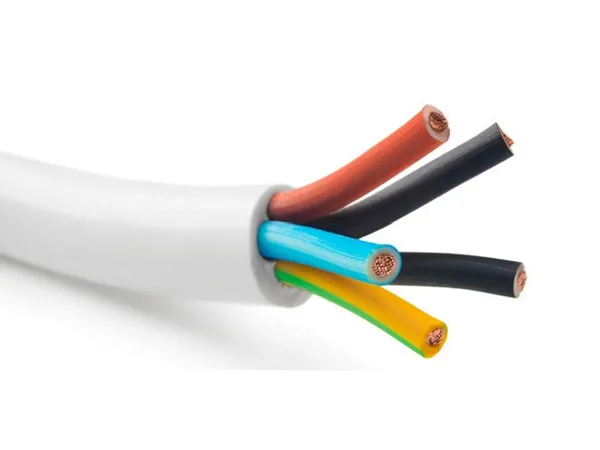

Rubber cables, often referred to as flexible cables, are electrical cables with conductors (typically copper) encased in rubber-based insulation and sheathing materials, such as ethylene propylene rubber (EPR), chloroprene rubber (CR), or chlorinated polyethylene (CPE). These materials provide superior flexibility, resistance to environmental stressors, and mechanical durability compared to PVC or XLPE cables. Rubber cables are used for power, control, or signal transmission in industrial environments, with voltage ratings typically ranging from 300/500 V to 0.6/1 kV, and are available in single-core or multi-core configurations.

Rubber cables are designed to meet the demands of industrial environments, with specific characteristics ensuring performance under harsh conditions:

| Characteristic | Description |

|---|---|

| Oil Resistance | Resists oils, greases, lubricants |

| UV Resistance | Withstands prolonged UV exposure |

| Flexibility | Supports tight bending, dynamic movement |

| Temperature Range | -25°C to 90°C (up to 120°C short-term) |

Selecting the right rubber cable for industrial use involves evaluating specific criteria related to oil, UV, and flexibility factors:

| Selection Criterion | Key Considerations |

|---|---|

| Oil Resistance | CR/NBR sheathing, oil immersion test |

| UV Resistance | EPR/CPE compounds, UV aging tests |

| Flexibility | Class 5/6 conductors, low bending radius |

| Electrical Requirements | Ampacity, voltage rating |

Rubber cables are used in various industrial applications due to their robustness and flexibility:

| Application | Key Requirements |

|---|---|

| Manufacturing | Oil resistance, mechanical strength |

| Construction | UV resistance, flexibility |

| Renewable Energy | UV, weather resistance |

| Mining | Oil resistance, abrasion resistance |

| Challenge | Solution |

|---|---|

| Oil-Induced Degradation | Use CR/NBR sheathing, verify oil resistance tests |

| UV Degradation | Select EPR/CPE cables with UV aging certification |

| Mechanical Wear | Choose cables with high abrasion resistance, proper installation |

| Cost Constraints | Balance cable specifications with application needs, source from reputable suppliers |

Rubber cables are an ideal choice for industrial applications due to their exceptional oil resistance, UV resistance, and flexibility. By selecting cables with appropriate materials (e.g., CR, EPR, or CPE), stranded conductors, and compliance with industry standards, users can ensure reliable performance in harsh environments like manufacturing, construction, and renewable energy systems. Addressing challenges such as oil-induced degradation and mechanical wear through careful material selection and proper installation practices enhances system safety and longevity, making rubber cables a durable and versatile solution for industrial power and control applications.

High quality copper conductor rubber compound sheath PE PVC Insulation rubber ca

H05VV-F Cable is a type of flexible, insulated electrical cable commonly used in

The H05RN-F cable is a type of flexible rubber-sheathed electrical cable commonl

Welding cables are specialized electrical cables designed to handle the high amp