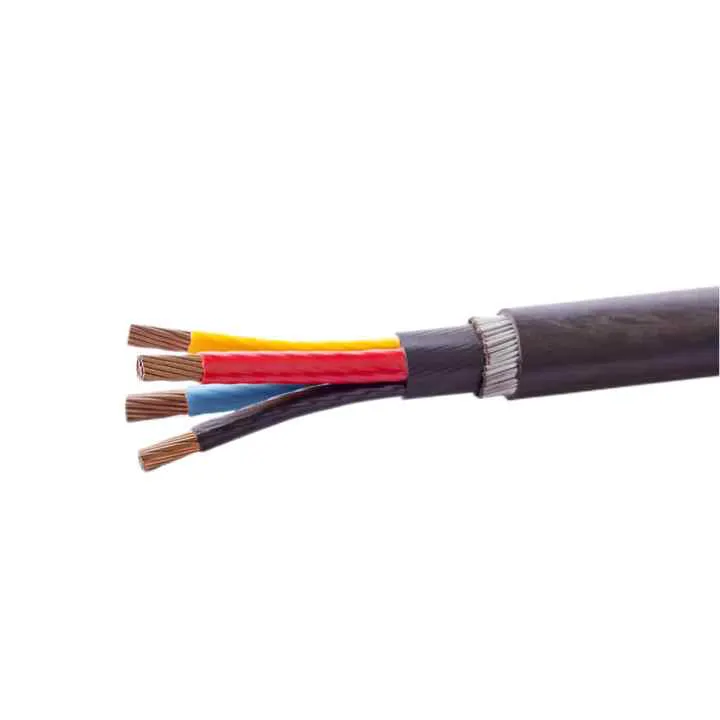

Control Cable with Steel-Braided Shield: Applications and Specifications

Time: 2025-07-31 08:25:15

Source: Henan Province Jianyun Cable Co., Ltd.

Control cables with steel-braided shields are specialized electrical cables designed for reliable signal transmission in industrial environments, offering protection against electromagnetic interference (EMI) and mechanical stress. The steel-braided shield enhances durability and shielding effectiveness, making these cables suitable for demanding applications. This guide provides a detailed overview of the applications, specifications, and selection criteria for steel-braided control cables, presented in a formal and structured manner.

Table of Contents

1. Overview of Steel-Braided Control Cables

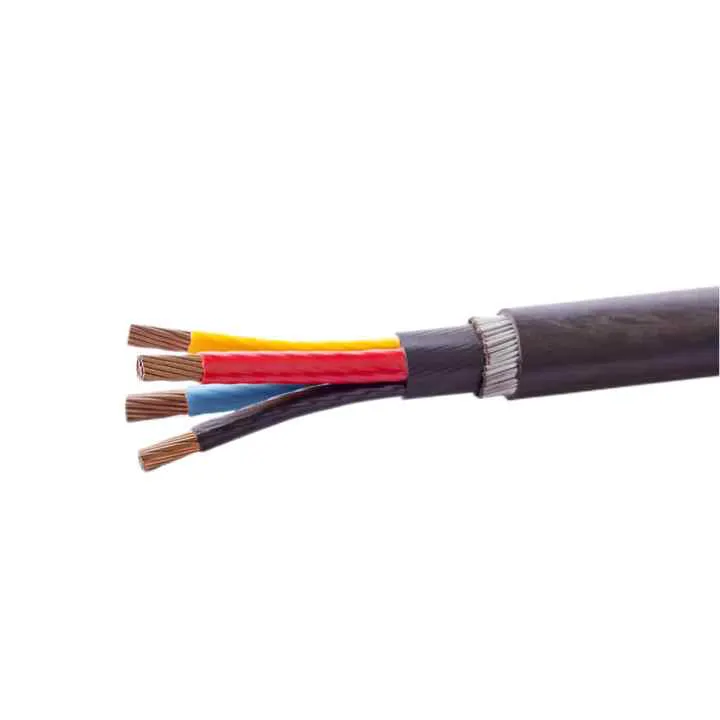

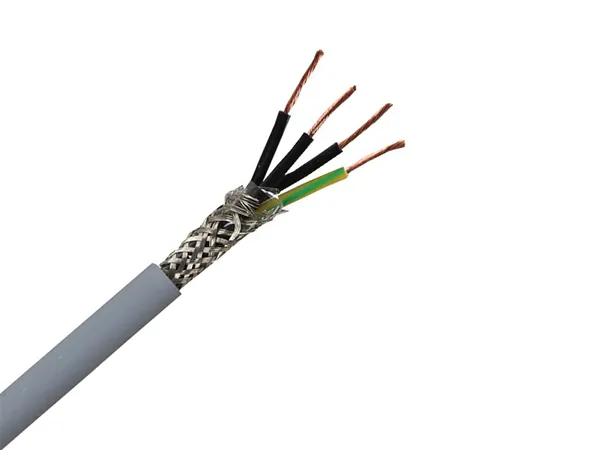

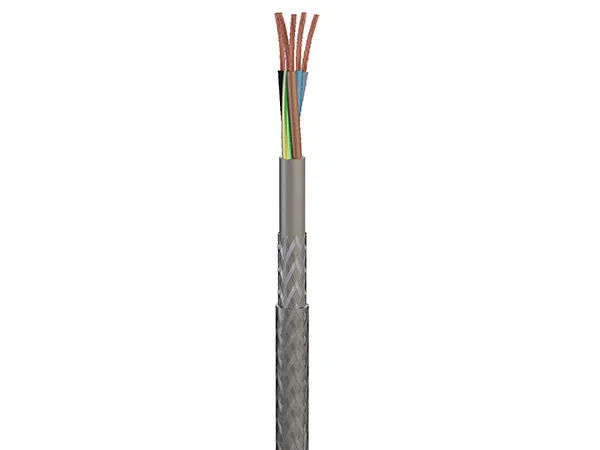

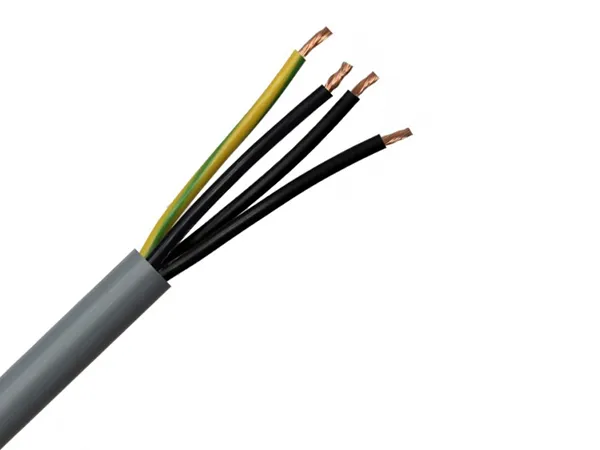

Control cables with steel-braided shields are multi-core cables used to transmit low-voltage signals for controlling machinery, equipment, or automated systems. They typically consist of copper conductors, insulated with materials like polyvinyl chloride (PVC) or cross-linked polyethylene (XLPE), and are encased in a steel-braided shield for EMI protection and mechanical strength. An outer sheath, often made of PVC, rubber, or polyurethane (PUR), provides additional environmental resistance. These cables are designed for voltages ranging from 300/300 V to 0.6/1 kV and are used in environments with high electromagnetic noise or mechanical stress.

2. Key Specifications

Steel-braided control cables are defined by specific technical specifications to ensure performance in industrial applications:

-

Conductor: Stranded copper (Class 5 or 6 per IEC 60228) for flexibility, typically 0.5 mm² to 2.5 mm² per core.

-

Insulation: PVC, XLPE, or EPR, providing electrical isolation and temperature resistance (up to 70°C for PVC, 90°C for XLPE/EPR).

-

Shielding: Steel braid (galvanized or stainless) offering >80% coverage for EMI protection and mechanical durability.

-

Outer Sheath: PVC, PUR, or rubber (e.g., chloroprene) for resistance to abrasion, chemicals, and environmental factors.

-

Voltage Rating: 300/300 V, 300/500 V, or 0.6/1 kV, suitable for low-voltage control circuits.

-

Temperature Range: Typically -25°C to 70°C (PVC) or -40°C to 90°C (rubber/PUR), with short-term ratings up to 120°C.

-

Flexibility: Bending radius of 6–10 times cable diameter for static installations, 10–15 times for dynamic applications.

-

Environmental Resistance: Resistant to oil, UV, moisture, and chemicals, depending on sheath material.

-

Flame Retardancy: Often halogen-free and flame-retardant to minimize fire risks and toxic emissions.

|

Specification

|

Details

|

|

Conductor

|

Stranded copper, 0.5–2.5 mm²

|

|

Shielding

|

Steel braid, >80% coverage

|

|

Voltage Rating

|

300/300 V to 0.6/1 kV

|

|

Temperature Range

|

-25°C to 90°C

|

|

Bending Radius

|

6–15 times cable diameter

|

3. Applications in Industrial Settings

Steel-braided control cables are used in various industrial applications where EMI protection and mechanical durability are critical:

-

Automation and Robotics: Transmitting control signals to robotic arms and automated machinery, where flexibility and EMI shielding ensure reliable operation in high-noise environments.

-

Manufacturing Plants: Controlling motors, conveyors, and sensors in factories with electromagnetic interference from heavy machinery (e.g., steel or automotive plants).

-

Oil and Gas Facilities: Used in control systems for pumps and valves, where oil-resistant sheathing and steel braiding protect against harsh chemicals and mechanical stress.

-

Construction Sites: Powering temporary control systems for cranes and heavy equipment, leveraging UV and abrasion resistance.

-

Renewable Energy: Connecting control systems in wind turbines or solar inverters, where UV and weather resistance are essential.

-

Marine and Offshore: Used in shipboard or offshore platforms for control circuits, with steel braiding providing corrosion resistance and mechanical protection.

|

Application

|

Key Requirements

|

|

Automation

|

EMI shielding, flexibility

|

|

Manufacturing

|

EMI protection, durability

|

|

Oil and Gas

|

Oil resistance, mechanical strength

|

|

Renewable Energy

|

UV, weather resistance

|

4. Selection Criteria

Selecting the appropriate steel-braided control cable involves evaluating the following criteria:

-

EMI Protection Needs: Ensure steel braid provides >80% coverage for high-EMI environments (e.g., near motors or variable frequency drives).

-

Electrical Requirements:

-

Select conductor size (e.g., 0.75 mm² for signals, 2.5 mm² for higher current) based on ampacity (e.g., 0.75 mm² ≈ 12 A, 2.5 mm² ≈ 25 A at 60°C).

-

Match voltage rating to the control system (e.g., 300/500 V for most industrial controls).

-

Environmental Conditions:

-

Choose rubber or PUR sheathing for oil and chemical resistance in harsh settings (e.g., oil refineries).

-

Select UV-resistant sheathing for outdoor applications (e.g., construction or solar farms).

-

Flexibility: Opt for Class 5/6 stranded conductors and flexible sheathing (e.g., EPR or PUR) for dynamic applications like robotics.

-

Mechanical Durability: Ensure steel braiding and robust sheathing withstand abrasion, impact, or crushing in rugged environments.

-

Safety Requirements: Use halogen-free, flame-retardant cables in fire-sensitive areas to reduce toxic emissions.

|

Criterion

|

Consideration

|

|

EMI Protection

|

Steel braid, >80% coverage

|

|

Electrical

|

Ampacity, voltage rating

|

|

Environmental

|

Oil, UV, chemical resistance

|

|

Flexibility

|

Class 5/6 conductors, flexible sheath

|

5. Challenges and Solutions

|

Challenge

|

Solution

|

|

EMI Interference

|

Ensure high-coverage steel braiding, proper grounding

|

|

Environmental Degradation

|

Use oil/UV-resistant sheathing (e.g., PUR, rubber)

|

|

Mechanical Damage

|

Select robust steel braiding, abrasion-resistant sheath

|

|

Cost Constraints

|

Balance specifications with application needs, source from reputable suppliers

|

6. Conclusion

Control cables with steel-braided shields are essential for reliable signal transmission in industrial environments, offering superior EMI protection and mechanical durability. Their applications span automation, manufacturing, oil and gas, and renewable energy, where steel braiding ensures performance in high-noise and harsh conditions. By selecting cables with appropriate conductor sizes, voltage ratings, and sheathing materials (e.g., PUR or rubber), and addressing challenges like EMI and environmental degradation, users can ensure safe and efficient operation. Careful consideration of specifications and application requirements guarantees long-term reliability in demanding industrial settings.