Time: 2025-07-31 08:34:14 Source: Henan Province Jianyun Cable Co., Ltd.

Control and rubber cables rated at 300/500 V are widely used in industrial applications for transmitting control signals and power to machinery and equipment. These cables, often featuring flexible conductors and robust insulation like rubber or PVC, are designed for reliability in dynamic and harsh environments. Implementing best practices for their selection, installation, and maintenance ensures safety, efficiency, and longevity. This guide outlines key best practices for using 300/500 V control and rubber cables, presented in a formal and structured manner.

Control cables rated at 300/500 V are multi-core cables used for transmitting low-voltage control signals or power in industrial settings, such as automation systems, machinery, and instrumentation. Rubber cables, often used as control cables, feature flexible conductors (typically stranded copper, Class 5 or 6 per IEC 60228) and rubber-based insulation or sheathing (e.g., ethylene propylene rubber (EPR), chloroprene rubber (CR), or chlorinated polyethylene (CPE)). These cables offer flexibility, oil resistance, and durability in environments with mechanical stress, temperatures from -25°C to 90°C, and exposure to oil or UV radiation. They are commonly used in both fixed and dynamic applications.

Selecting the right 300/500 V control or rubber cable ensures compatibility with the application and environment:

| Selection Practice | Key Considerations |

|---|---|

| Electrical Requirements | Current, 300/500 V rating |

| Materials | Rubber for oil/UV, PVC for indoor |

| Flexibility | Class 5/6 conductors, bending radius |

| Safety | Halogen-free, flame-retardant |

Proper installation maximizes cable performance and safety:

| Installation Practice | Key Actions |

|---|---|

| Bending Radius | 6–15 times cable diameter |

| Cable Management | Use clips, trays, avoid tight clamping |

| Environmental Protection | UV/oil-resistant sheathing or conduits |

| Grounding/Shielding | Connect shield to ground, use in high-EMI areas |

Regular maintenance extends the lifespan of control and rubber cables:

| Maintenance Practice | Key Actions |

|---|---|

| Inspections | Check wear, corrosion, terminations |

| Cleaning | Remove oil/chemical residues |

| Performance Monitoring | Test signal integrity, insulation resistance |

| Replacement | Replace damaged cables promptly |

300/500 V control and rubber cables are used in various industrial applications:

| Application | Key Requirements |

|---|---|

| Automation | EMI shielding, signal reliability |

| Machinery | Oil resistance, durability |

| Construction | Flexibility, UV resistance |

| Robotics | High flexibility, EMI protection |

| Challenge | Solution |

|---|---|

| Environmental Degradation | Use oil/UV-resistant rubber sheathing, protective conduits |

| Mechanical Wear | Adhere to bending radius, use robust cable management |

| EMI Interference | Use shielded cables, ensure proper grounding |

| Overheating | Apply derating factors, avoid overloading |

Implementing best practices for 300/500 V control and rubber cables ensures reliable performance in industrial applications. Careful selection based on electrical, environmental, and flexibility requirements, combined with proper installation techniques and regular maintenance, minimizes risks of failure and extends cable lifespan. These cables are ideal for automation, machinery, construction, and robotics, offering durability and safety in harsh conditions. By addressing challenges like environmental degradation and EMI through appropriate materials and practices, users can achieve efficient and safe operation for 25–30 years.

Copper core control cable is a high-performance cable designed for transmitting

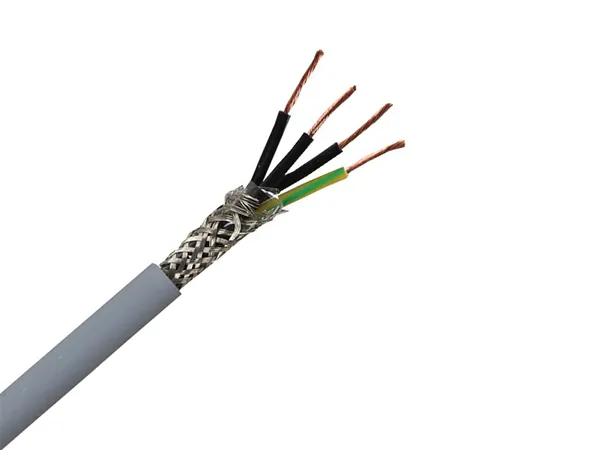

CY control cable is a high-quality, shielded cable designed for transmitting con

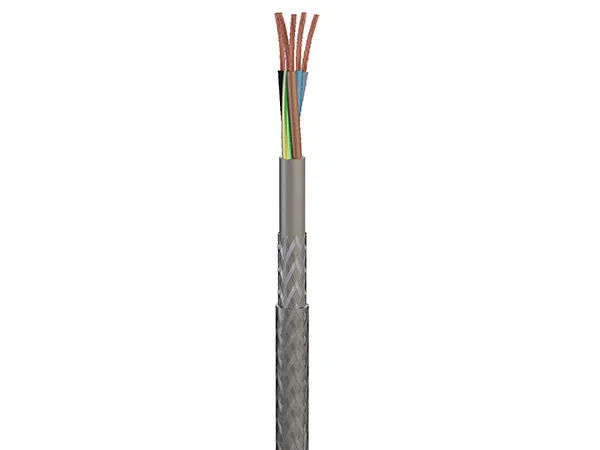

SY control cable is a type of flexible control cable designed for industrial aut

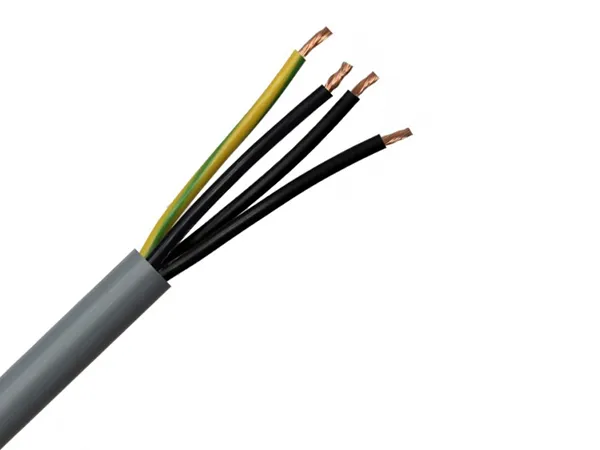

YY control cable is a type of multi-core electrical cable specifically designed