H07V-K vs. H05VV-F: Which Flexible Cable Suits Your Project?

Time: 2025-07-31 08:55:33

Source: Henan Province Jianyun Cable Co., Ltd.

Selecting the appropriate flexible cable for a project is critical to ensure safety, performance, and durability. H07V-K and H05VV-F are two common types of flexible cables used in electrical installations, each designed for specific applications based on their construction, voltage ratings, and environmental suitability. This guide provides a detailed comparison of H07V-K and H05VV-F cables, focusing on their specifications, applications, and selection criteria, presented in a formal and structured manner.

Table of Contents

1. Overview of H07V-K and H05VV-F Cables

H07V-K and H05VV-F are flexible cables standardized under European Harmonized (HAR) designations, commonly used for low-voltage electrical installations. Both cables feature stranded copper conductors for flexibility but differ in construction, insulation, and intended use:

-

H07V-K: A single-core, flexible cable with PVC insulation, designed for fixed installations in conduits, panels, or equipment wiring.

-

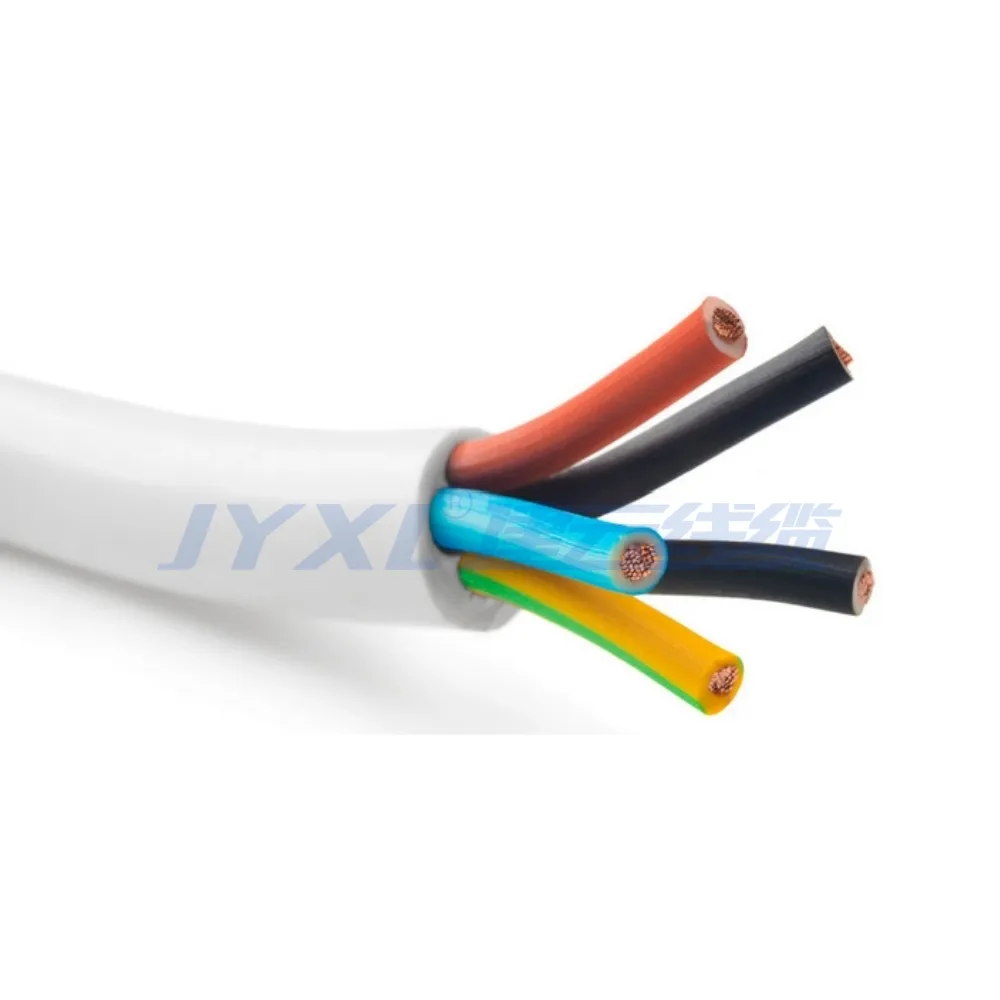

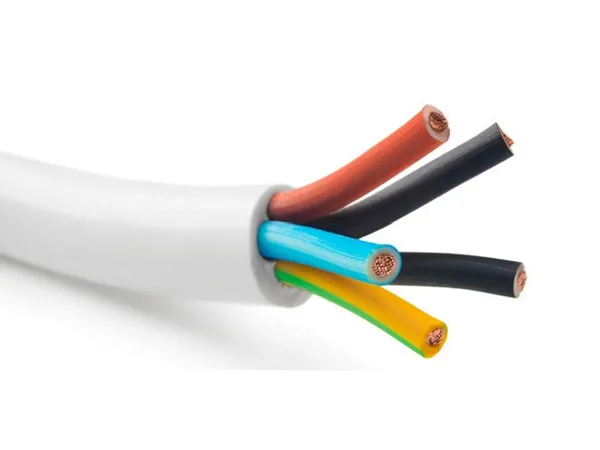

H05VV-F: A multi-core, flexible cable with PVC insulation and a PVC outer sheath, suitable for portable appliances and light-duty applications requiring flexibility.

Both cables are designed for low-voltage applications, typically in residential, commercial, or light industrial settings, and are valued for their flexibility and ease of installation.

2. Key Specifications and Differences

The primary differences between H07V-K and H05VV-F cables lie in their construction, voltage ratings, and environmental suitability:

-

Construction:

-

H07V-K: Single-core with stranded copper conductors (Class 5 per IEC 60228) and PVC insulation. No outer sheath, intended for protected installations.

-

H05VV-F: Multi-core (2–5 cores) with stranded copper conductors (Class 5), PVC insulation, and a PVC outer sheath for added protection and flexibility.

-

Voltage Rating:

-

H07V-K: Rated at 450/750 V (450 V to ground, 750 V between conductors), suitable for higher voltage applications.

-

H05VV-F: Rated at 300/500 V, designed for lower voltage applications like household appliances.

-

Conductor Size:

-

H07V-K: Available in sizes from 1.5 mm² to 240 mm², supporting a wide range of currents (e.g., 1.5 mm² ≈ 18 A, 6 mm² ≈ 40 A at 60°C).

-

H05VV-F: Typically available in smaller sizes (0.75 mm² to 4 mm²), suitable for lower currents (e.g., 0.75 mm² ≈ 12 A, 2.5 mm² ≈ 25 A).

-

Temperature Range:

-

H07V-K: -25°C to 70°C for fixed installations, with short-term tolerance up to 160°C.

-

H05VV-F: -15°C to 70°C, designed for flexible use but less suited for extreme cold.

-

Flexibility:

-

H07V-K: Highly flexible due to Class 5 conductors, but limited to fixed or semi-fixed applications due to lack of outer sheath.

-

H05VV-F: Highly flexible with a protective sheath, ideal for dynamic applications like movable appliances.

-

Environmental Resistance:

-

H07V-K: Limited resistance to oil, UV, or moisture due to single-layer PVC insulation; requires conduit or enclosure for protection.

-

H05VV-F: Moderate resistance to abrasion and moisture due to PVC sheath, but not suitable for harsh chemical or UV exposure.

|

Specification

|

H07V-K

|

H05VV-F

|

|

Construction

|

Single-core, PVC insulation

|

Multi-core, PVC insulation + sheath

|

|

Voltage Rating

|

450/750 V

|

300/500 V

|

|

Conductor Size

|

1.5–240 mm²

|

0.75–4 mm²

|

|

Temperature Range

|

-25°C to 70°C

|

-15°C to 70°C

|

|

Flexibility

|

Fixed/semi-fixed

|

Dynamic applications

|

3. Applications

H07V-K and H05VV-F cables are suited to different applications based on their design:

-

H07V-K:

-

Fixed Installations: Wiring in control panels, switchboards, or electrical enclosures where flexibility aids installation in tight spaces.

-

Equipment Wiring: Internal wiring for machines, lighting fixtures, or appliances requiring a single conductor.

-

Conduit Installations: Used within conduits or trunking for building wiring in residential or commercial settings.

-

H05VV-F:

-

Portable Appliances: Power cords for household devices like vacuum cleaners, lamps, or kitchen appliances requiring multi-core flexibility.

-

Light Industrial Use: Control or power connections for movable equipment in workshops or small factories.

-

Temporary Installations: Extension cords or temporary power setups in events or construction sites.

|

Cable Type

|

Primary Applications

|

|

H07V-K

|

Control panels, equipment wiring, conduit installations

|

|

H05VV-F

|

Portable appliances, light industrial, temporary setups

|

4. Selection Criteria

Choosing between H07V-K and H05VV-F depends on project requirements:

-

Electrical Requirements:

-

Use H07V-K for systems up to 750 V or higher current loads (e.g., 6 mm² for 40 A).

-

Choose H05VV-F for systems up to 500 V with lower currents (e.g., 2.5 mm² for 25 A).

-

Installation Type:

-

Select H07V-K for fixed or protected installations (e.g., inside conduits or panels).

-

Opt for H05VV-F for dynamic or exposed applications (e.g., power cords, movable equipment).

-

Environmental Conditions:

-

Use H07V-K in protected environments (e.g., indoors or in conduits) due to its lack of outer sheath.

-

Choose H05VV-F for moderate exposure to abrasion or moisture, but avoid harsh chemicals or UV-heavy environments.

-

Number of Conductors:

-

H07V-K for single-conductor needs (e.g., single-phase circuits or grounding).

-

H05VV-F for multi-core needs (e.g., three-core for live, neutral, and ground in appliances).

-

Cost Considerations:

-

H07V-K is generally cheaper for single-core applications but requires additional protection (e.g., conduits).

-

H05VV-F is more expensive due to multi-core construction and sheathing but offers versatility for portable devices.

|

Criterion

|

H07V-K

|

H05VV-F

|

|

Voltage/Current

|

Up to 750 V, higher currents

|

Up to 500 V, lower currents

|

|

Installation

|

Fixed, protected

|

Dynamic, exposed

|

|

Conductors

|

Single-core

|

Multi-core

|

|

Cost

|

Lower

|

Higher

|

5. Challenges and Solutions

|

Challenge

|

Solution

|

|

Environmental Exposure (H07V-K)

|

Use conduits or enclosures for protection against moisture, UV, or chemicals

|

|

Limited Flexibility (H05VV-F)

|

Ensure proper cable management to avoid excessive bending or stress

|

|

Overloading

|

Calculate load, apply derating factors (e.g., 0.91 for 40°C), select appropriate size

|

|

Compatibility

|

Verify voltage ratings and connector compatibility (e.g., terminal blocks for H07V-K, plugs for H05VV-F)

|

6. Conclusion

H07V-K and H05VV-F cables serve distinct purposes in electrical installations, with H07V-K suited for fixed, single-core applications like control panels and equipment wiring, and H05VV-F ideal for dynamic, multi-core applications like portable appliances. By evaluating electrical requirements, installation type, environmental conditions, and cost, users can select the appropriate cable for their project. Addressing challenges such as environmental exposure and overloading through proper selection and installation practices ensures safety, reliability, and a lifespan of 25–30 years for both cable types.