How to Perform Quality Checks on Multi-Core Control Cables

Time: 2025-07-31 09:11:00

Source: Henan Province Jianyun Cable Co., Ltd.

Multi-core control cables are critical components in industrial and automation systems, transmitting control signals and low-voltage power to machinery and equipment. Ensuring their quality through systematic checks is essential for safety, reliability, and performance. This guide outlines a structured approach to performing quality checks on multi-core control cables, covering visual inspections, electrical tests, and environmental assessments, presented in a formal and professional manner.

Table of Contents

1. Overview of Multi-Core Control Cables

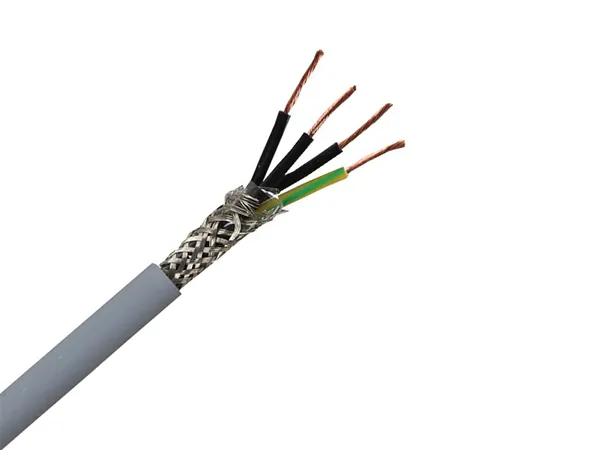

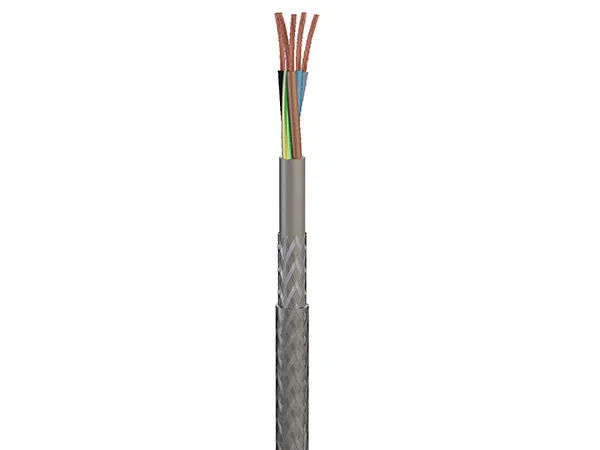

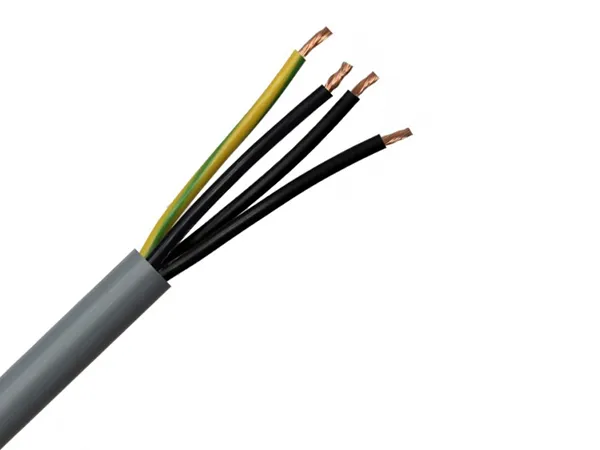

Multi-core control cables consist of multiple insulated conductors (typically stranded copper, Class 5 or 6 per IEC 60228) encased in a protective outer sheath, often made of PVC, rubber, or polyurethane (PUR). They are used for transmitting control signals or power in applications such as automation, robotics, and industrial machinery, with voltage ratings typically ranging from 300/300 V to 0.6/1 kV. These cables may include shielding (e.g., copper or steel braid) for electromagnetic interference (EMI) protection and are designed to withstand environmental stressors like oil, UV radiation, and mechanical wear.

2. Key Quality Parameters

Quality checks for multi-core control cables focus on the following parameters to ensure performance and safety:

-

Physical Integrity: No cuts, abrasions, or cracks in the insulation or outer sheath; uniform construction and proper shielding coverage.

-

Electrical Performance: Adequate insulation resistance, conductor continuity, and voltage withstand capability to prevent signal loss or electrical faults.

-

Shielding Effectiveness: Proper EMI protection, typically >80% coverage for braided shields, to ensure reliable signal transmission.

-

Environmental Resistance: Resistance to oil, UV, moisture, and temperature extremes, as specified for the application (e.g., -25°C to 90°C).

-

Mechanical Durability: Flexibility and resistance to bending, abrasion, or impact, suitable for static or dynamic use.

-

Compliance with Standards: Adherence to standards for safety and performance.

|

Parameter

|

Description

|

|

Physical Integrity

|

No cuts, abrasions, or cracks

|

|

Electrical Performance

|

Insulation resistance, continuity, voltage withstand

|

|

Shielding Effectiveness

|

>80% coverage for EMI protection

|

|

Environmental Resistance

|

Oil, UV, moisture, temperature resistance

|

3. Quality Check Procedures

Perform the following quality checks to verify the condition of multi-core control cables:

-

Visual Inspection:

-

Examine the outer sheath for cuts, abrasions, cracks, or discoloration indicating UV or chemical damage.

-

Check for uniform thickness and proper adhesion of insulation and sheath.

-

Verify the presence and integrity of shielding (e.g., steel or copper braid) by inspecting exposed sections or cut ends.

-

Ensure conductor markings (e.g., color coding or numbering) are clear for correct identification during installation.

-

Conductor Continuity Test:

-

Use a multimeter to check continuity for each conductor, ensuring no open circuits or breaks.

-

Connect the multimeter probes to both ends of each core and confirm a resistance reading close to 0 ohms (e.g., <0.1 ohms for short lengths).

-

Insulation Resistance Test:

-

Use a megohmmeter (megger) to measure insulation resistance between each conductor and ground, and between conductors.

-

Apply a test voltage (e.g., 500 V DC for 300/500 V cables) for 1 minute; expect resistance >100 MΩ for new cables.

-

Low readings (<10 MΩ) indicate insulation damage or moisture ingress.

-

Voltage Withstand Test:

-

Apply a high-voltage test (e.g., 2 kV AC for 1 minute for 300/500 V cables) using a hipot tester to verify insulation integrity.

-

Ensure no breakdown or arcing occurs, indicating the cable can withstand rated voltages.

-

Shielding Continuity and Effectiveness:

-

Test shield continuity using a multimeter to confirm the braid is intact and properly grounded.

-

Verify shielding effectiveness by checking for EMI susceptibility in a controlled test environment or confirming >80% braid coverage through manufacturer documentation.

-

Environmental Resistance Tests:

-

Inspect manufacturer test reports for oil resistance (e.g., immersion in oil per EN 60811-404), UV resistance (e.g., accelerated UV aging), or temperature performance.

-

For critical applications, perform spot checks by exposing cable samples to oil or UV light and checking for degradation (e.g., cracking or loss of flexibility).

-

Mechanical and Flexibility Tests:

-

Bend the cable to the minimum specified radius (e.g., 6–10 times diameter for static, 10–15 times for dynamic) and check for insulation or sheath damage.

-

Perform a flexing test for dynamic applications by repeatedly bending a sample to simulate operational conditions, ensuring no conductor fatigue.

|

Check Type

|

Procedure

|

|

Visual Inspection

|

Check sheath, insulation, shielding, markings

|

|

Continuity Test

|

Multimeter, <0.1 ohms per core

|

|

Insulation Resistance

|

Megohmmeter, >100 MΩ at 500 V DC

|

|

Voltage Withstand

|

Hipot tester, 2 kV AC, no breakdown

|

|

Shielding

|

Continuity, >80% coverage

|

4. Tools and Equipment

The following tools are required for effective quality checks:

-

Multimeter: For continuity and basic resistance tests.

-

Megohmmeter: For measuring insulation resistance (e.g., 500 V or 1000 V models).

-

Hipot Tester: For high-voltage withstand tests.

-

Cable Stripping Tools: To expose conductors or shielding for inspection without damaging the cable.

-

Environmental Test Equipment: For lab-based oil, UV, or temperature tests (optional for on-site checks).

-

Magnifying Glass or Microscope: For detailed inspection of insulation or sheath defects.

|

Tool

|

Purpose

|

|

Multimeter

|

Continuity, resistance tests

|

|

Megohmmeter

|

Insulation resistance measurement

|

|

Hipot Tester

|

Voltage withstand testing

|

|

Stripping Tools

|

Expose conductors/shielding

|

5. Challenges and Solutions

|

Challenge

|

Solution

|

|

Insulation Damage

|

Perform insulation resistance and hipot tests; replace defective cables

|

|

EMI Issues

|

Verify shield continuity and coverage; ensure proper grounding

|

|

Environmental Degradation

|

Check manufacturer test reports, use protective conduits for harsh conditions

|

|

Inconsistent Test Results

|

Calibrate test equipment, follow standardized procedures

|

6. Documentation and Compliance

Proper documentation and compliance are critical for quality assurance:

-

Record Test Results: Document visual inspection findings, continuity, insulation resistance, and voltage withstand test results, including date, cable batch, and tester details.

-

Verify Certifications: Ensure cables meet relevant standards, and request manufacturer test reports for oil, UV, or flame-retardant properties.

-

Maintain Traceability: Log cable batch numbers and supplier details to track performance and facilitate recalls if needed.

-

Comply with Regulations: Adhere to local electrical codes for testing and installation requirements.

7. Conclusion

Performing quality checks on multi-core control cables involves systematic visual inspections, electrical tests, and environmental assessments to ensure reliability and safety in industrial applications. By verifying physical integrity, electrical performance, shielding effectiveness, and environmental resistance using tools like multimeters and megohmmeters, users can confirm cable quality. Addressing challenges such as insulation damage or EMI through standardized procedures and proper documentation ensures compliance and long-term performance, supporting a lifespan of 25–30 years in demanding environments.