Time: 2025-12-16 14:11:31 Source: Henan Province Jianyun Cable Co., Ltd.

In modern building and infrastructure projects, fire safety is paramount. Two common terms—halogen free (often LSZH or Low Smoke Zero Halogen) and fire resistant cables—are frequently confused, yet they address different risks. Halogen free cables prioritize low toxicity and smoke during combustion, while fire resistant cables focus on maintaining circuit integrity under flame exposure. Understanding their differences helps engineers, installers, and specifiers choose the right cable for life safety and compliance in 2025's increasingly regulated environment.

Traditional PVC-insulated cables release toxic halogen gases (like chlorine) and dense smoke when burned, endangering lives through inhalation and obscuring escape routes. Halogen free cables mitigate this, while fire resistant cables ensure critical systems (alarms, sprinklers, emergency lighting) remain operational during fires. Both enhance safety but serve distinct purposes—often used together in high-risk areas.

Halogen free cables use thermoplastic or thermoset compounds without halogens (fluorine, chlorine, bromine, iodine). When exposed to fire, they produce minimal smoke and no corrosive acid gases, reducing secondary damage to equipment and health risks. Common materials include polyolefin-based compounds or EVA with mineral fillers. They meet low smoke (IEC 61034) and zero halogen (IEC 60754-1/2) tests, ideal for enclosed public spaces.

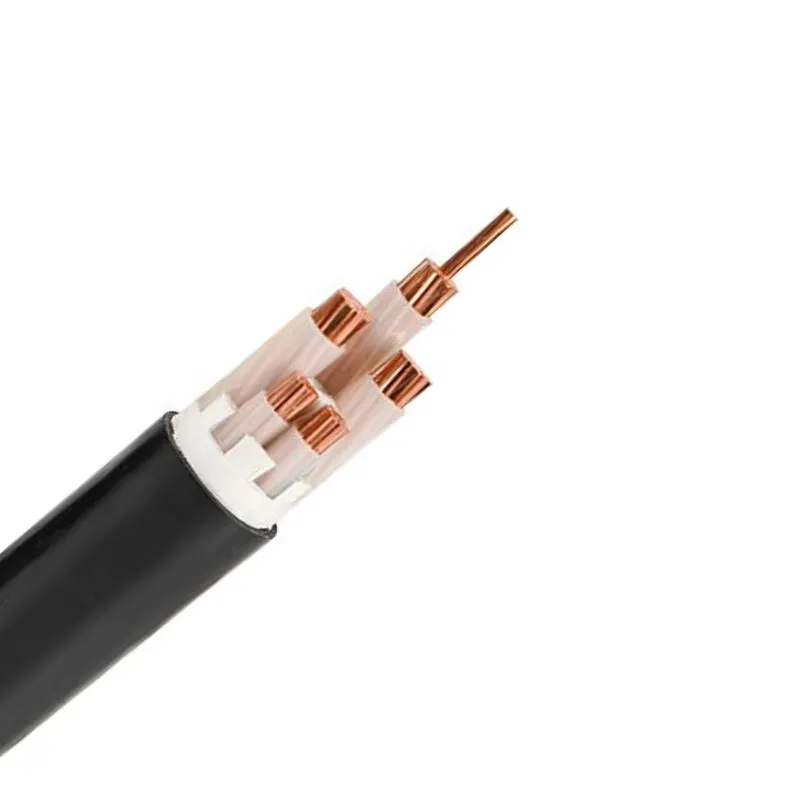

Fire resistant cables maintain circuit functionality for a specified time under direct flame, typically using mica tape wrapped around conductors plus special silicone or ceramic-forming insulation. They withstand temperatures up to 950°C (e.g., for 90-180 minutes per BS 6387 or IEC 60331), ensuring power to emergency systems. Smoke and gas emission are secondary concerns unless combined with LSZH sheaths.

| Aspect | Halogen Free (LSZH) | Fire Resistant |

|---|---|---|

| Primary Purpose | Reduce toxic smoke and corrosive gases | Maintain circuit operation during fire |

| Behavior in Fire | Low smoke, non-corrosive emissions | Continues functioning under flame/shock/water |

| Key Materials | Halogen-free polymers (EVA, PE compounds) | Mica tape + silicone/ceramic insulation |

| Testing Focus | IEC 60754 (halogen), IEC 61034 (smoke) | IEC 60331/BS 6387 (circuit integrity) |

| Typical Duration | N/A (focus on emissions) | 30–180 minutes (PH30, PH120, etc.) |

| Cost | Moderately higher than PVC | Significantly higher due to mica/special layers |

Halogen free: IEC 60754-1 (no halogen acid gas), IEC 60754-2 (pH/conductivity), IEC 61034 (smoke density). Fire resistant: IEC 60331 (flame exposure), BS 6387 (CWZ: flame + water + shock), EN 50200 (PH classes). EU CPR mandates reaction-to-fire classes (EN 50575), often combining LSZH with B2ca or better.

Many modern cables integrate both: Mica-wrapped conductors with LSZH outer sheath, offering low toxicity and sustained operation. These are standard in stringent projects (e.g., BS 8519 category cables) and increasingly required under 2025 CPR updates.

Halogen free and fire resistant cables address complementary fire safety needs—evacuation visibility/toxicity vs. system continuity. While halogen free protects people and assets from secondary effects, fire resistant ensures life-saving systems function. In high-risk environments, combining both is best practice. Always specify based on risk assessment and local codes for optimal protection.

For cables meeting both halogen free and fire resistant requirements, contact Henan Province Jianyun Cable Co., Ltd. for customized, certified solutions.

CE Certification 450/750v H07VVF Flexible Copper PVC Insulated Ac Cable 3*2.5 Mm

low voltage copper conductor PVC insulation underground BV BVR cable for industr

PVC electric wires are one of the most widely used electrical conductors in resi

H07V-U wire is a flexible, low voltage electrical wire commonly used in industri