Time: 2025-06-15 16:09:01 Source: Henan Province Jianyun Cable Co., Ltd.

Selecting cables for manufacturing environments requires careful evaluation of operational demands, including mechanical stress, environmental conditions, and electrical performance. Flexible and rigid cables serve distinct purposes, with their suitability determined by factors such as movement frequency, installation constraints, and compliance with industry standards like IEC or UL. Manufacturers must prioritize durability, safety, and cost-efficiency while ensuring cables meet specific application requirements.

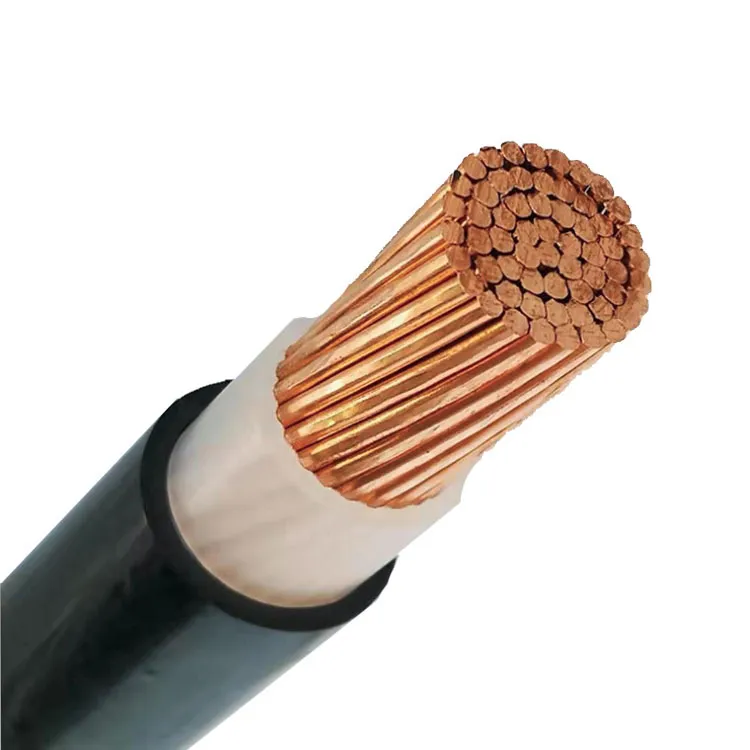

Flexible cables, typically constructed with stranded conductors and materials like TPU or PVC, offer high flexibility and a smaller bend radius, making them ideal for applications involving frequent movement or tight spaces. Rigid cables, often solid-core or with minimal stranding and stiffer jackets like XLPE, are less flexible and suited for fixed installations where minimal bending is required.

Flexible cables are designed to withstand repeated bending, vibration, and mechanical stress, making them suitable for dynamic applications like robotics or conveyor systems. Materials such as polyurethane enhance resistance to abrasion and chemicals. Rigid cables, while robust in static environments, are prone to fatigue under repeated stress, limiting their use in high-motion settings.

Flexible cables are easier to install in confined or complex layouts due to their pliability, reducing labor time. However, they may require more frequent maintenance in high-wear applications. Rigid cables, often used in conduit or fixed runs, are more challenging to install in tight spaces but require minimal maintenance once installed, provided they remain stationary.

Flexible cables are generally more expensive, with costs ranging from $10–$100+/meter, due to specialized materials and stranded conductor designs. Rigid cables, typically costing $5–$50/meter, are more cost-effective for static applications, as their simpler construction reduces manufacturing expenses.

Both flexible and rigid cables can use copper or aluminum conductors, with copper offering superior conductivity. Flexible cables with stranded conductors may have slightly higher resistance due to air gaps between strands, but this is negligible in most applications. Rigid cables, often solid-core, provide optimal conductivity for high-power, static installations but are less adaptable to dynamic systems.

| Property | Flexible Cables | Rigid Cables |

|---|---|---|

| Flexibility | High; small bend radius, ideal for dynamic applications | Low; suited for fixed installations |

| Durability | Resistant to bending and vibration; abrasion-resistant materials | Robust in static settings; prone to fatigue under stress |

| Installation | Easy in tight spaces; may require frequent maintenance | Challenging in complex layouts; low maintenance when static |

| Cost | Higher ($10–$100+/meter) | Lower ($5–$50/meter) |

| Conductivity | Slightly higher resistance due to stranded conductors | Optimal for high-power, static applications |

| Typical Applications | Robotics, conveyors, mobile equipment | Power grids, static machinery, control panels |

Choosing between flexible and rigid cables in manufacturing depends on the application’s mechanical and electrical demands. Flexible cables excel in dynamic environments, offering adaptability and durability for robotics and automation, while rigid cables are cost-effective and reliable for fixed power and control systems. Manufacturers should allocate 10–15% of system costs to cables, prioritizing certified materials like TPU or XLPE that meet IEC or UL standards. Evaluating performance against verified standards ensures reliability while avoiding overstated marketing claims.

CE Certification 450/750v H07VVF Flexible Copper PVC Insulated Ac Cable 3*2.5 Mm

low voltage copper conductor PVC insulation underground BV BVR cable for industr

PVC electric wires are one of the most widely used electrical conductors in resi

H07V-U wire is a flexible, low voltage electrical wire commonly used in industri