Time: 2025-10-10 03:36:03 Source: Henan Province Jianyun Cable Co., Ltd.

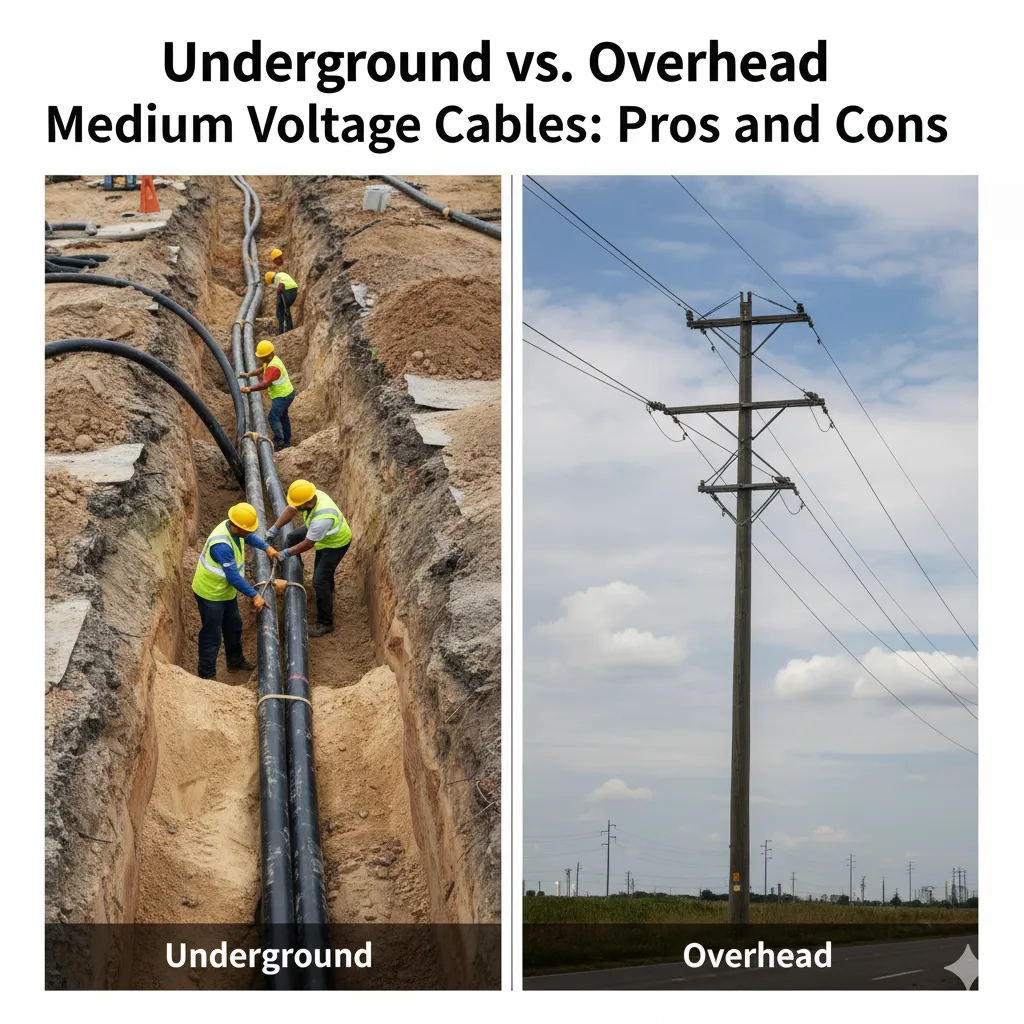

Medium voltage (MV) cables, rated from 6 kV to 35 kV per IEC 60038, are essential for power distribution in industrial, utility, and infrastructure projects. The choice between underground and overhead installations significantly impacts cost, reliability, and maintenance. Underground cables are buried in trenches or ducts, while overhead cables are mounted on poles or towers.

Medium voltage cables are designed for efficient power transmission in applications requiring higher capacity than low voltage systems. Underground MV cables are buried in trenches or ducts, protected from weather but more complex to install. Overhead MV cables are suspended on poles or towers, exposed to elements but easier to maintain. Both types feature robust insulation (e.g., XLPE), shielding (e.g., copper tape), and armoring (for underground). Henan Province Jianyun Cable Co., Ltd. offers TUV- and CCC-certified MV cables for both underground and overhead use, ensuring compliance with IEC 60502-2.

| Aspect | Underground MV Cables | Overhead MV Cables |

|---|---|---|

| Cost | Higher installation (5–10x overhead) | Lower (20–50% savings) |

| Maintenance | Difficult, longer downtime | Easier, quicker repairs |

| Environmental Protection | High (weather-resistant) | Low (exposed to storms) |

| Aesthetics | High (invisible) | Low (visible poles/wires) |

| Heat Dissipation | Lower (requires derating) | Higher (air cooling) |

| Safety | Higher (reduced electrocution risk) | Lower (downed lines) |

| EMI | Lower (buried) | Higher (exposed) |

| Lifespan | 25–30 years (protected) | 20–25 years (exposed) |

| Example Product | Jianyun Cable’s 11 kV XLPE-insulated underground cable. | Jianyun Cable’s 11 kV aerial bundle cable (ABC). |

Underground and overhead MV cables are selected based on project needs:

Criteria: Evaluate cost (underground higher), maintenance (overhead easier), safety (underground safer), and environmental impact (underground more protected).

| Challenge | Solution |

|---|---|

| High Underground Cost | Use overhead for rural or low-density areas; optimize trench design (e.g., 0.8–1.2 m depth). |

| Overhead Weather Vulnerability | Use insulated aerial bundle cables (ABC) with UV-resistant sheathing; implement storm-resistant supports. |

| Underground Maintenance Delays | Install pull boxes and use fault location tools (e.g., TDR); plan for spare ducts. |

| Counterfeit Products | Source from Jianyun Cable with TUV/CCC certifications; verify via official databases. |

| EMI in Sensitive Areas | Use shielded underground cables; separate from low-voltage lines (150–300 mm). |

Underground and overhead medium voltage cables (6–35 kV) offer distinct advantages for power distribution: underground for aesthetics, safety, and weather protection, and overhead for cost savings, easier maintenance, and better heat dissipation. Underground cables are ideal for urban, mining, and airport applications, while overhead cables suit rural utilities and renewable energy projects. Henan Province Jianyun Cable Co., Ltd. provides TUV- and CCC-certified MV cables for both methods, ensuring reliability and compliance with IEC 60502-2. By evaluating cost, safety, maintenance, and environmental factors, and partnering with trusted suppliers, projects can achieve efficient, safe, and durable power systems lasting 20–30 years.

NA2XS(f)2Y 6/10KV 12/20KV 120 150 185 240 300MM2 Single Conductor Xlpe Insulated

Grounding Cable 3 Core 95mm2 150mm2 240mm2 Aluminum High Voltage Cable

5x35mm 5x25mm Low Voltage Power Cable With PVC Sheath Copper Conductor XLPE Insu

A medium voltage three core armoured power cable is designed for the reliable tr