Time: 2025-10-15 07:12:48 Source: Henan Province Jianyun Cable Co., Ltd.

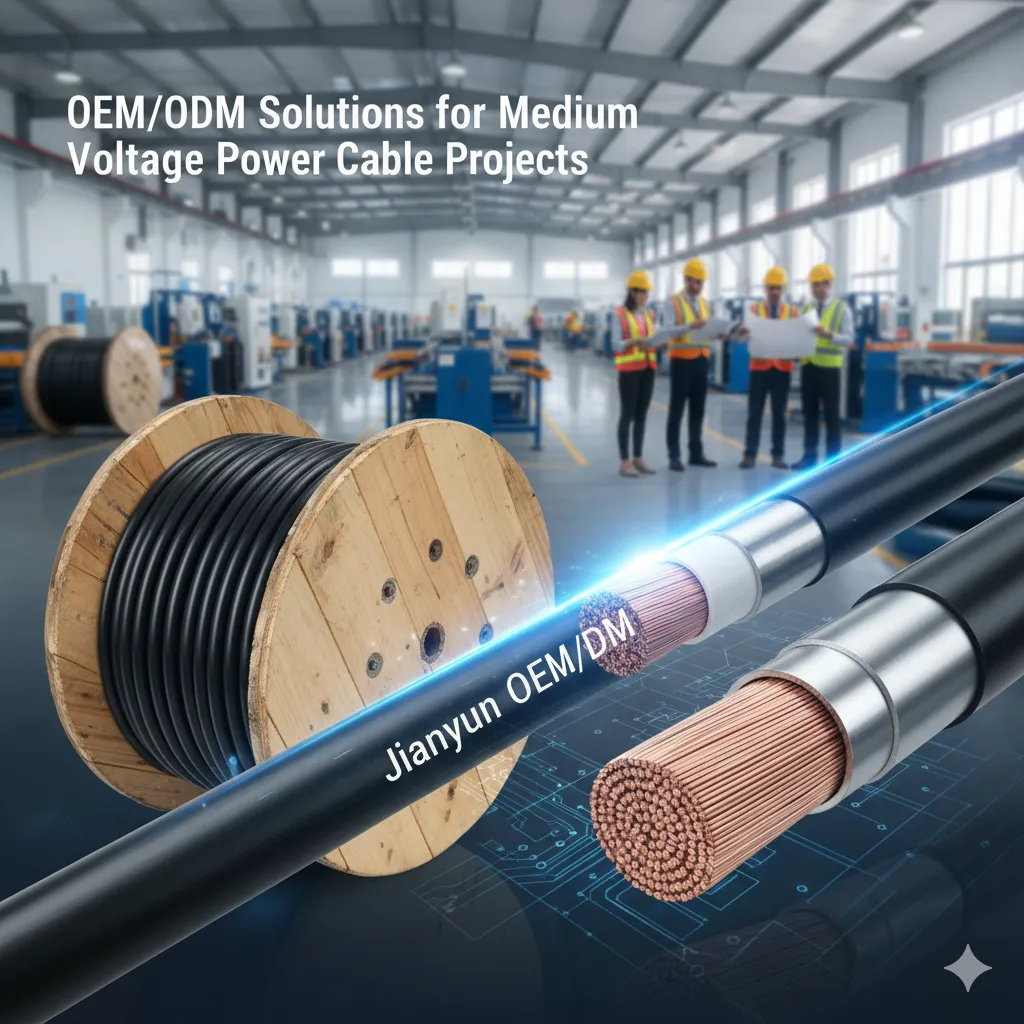

MV power cables, rated from 6 kV to 35 kV per IEC 60038, are used for efficient power transmission in applications requiring higher capacity than low voltage systems. OEM services involve manufacturing cables to a client’s provided specifications, while ODM includes design and manufacturing based on client needs. These solutions are ideal for projects needing custom conductor sizes (e.g., 50 mm² to 400 mm²), insulation (e.g., XLPE for 90°C operation), or armoring (e.g., SWA for mechanical protection). Manufacturers like Jianyun Cable offer OEM/ODM MV cables compliant with IEC 60502-2, ensuring reliability for global markets.

OEM/ODM solutions provide several advantages for MV power cable projects:

| Benefit | Details |

|---|---|

| Customization | Tailored specs (e.g., 12/20 kV, XLPE) |

| Cost-Effectiveness | Lower R&D, bulk discounts |

| Compliance | IEC 60502-2, TUV, CCC |

| Quality Control | In-house testing (<10 pC PD) |

| Scalability | High-volume production |

The OEM/ODM process involves several steps to ensure customized MV cables meet project needs:

| Step | Details |

|---|---|

| Define Requirements | Specify voltage, conductor, insulation |

| Select Manufacturer | ISO 9001, TUV-certified like Jianyun Cable |

| Design Phase | Blueprints, insulation thickness (3.4 mm) |

| Prototype | Testing (3.5 × U₀ voltage withstand) |

| Production | Quality checks (<10 pC PD) |

| Certification | IEC 60502-2, TUV reports |

| Delivery | ISPM 15 drums, DHL logistics |

OEM/ODM allows for tailored MV cables:

Compliance ensures MV cables meet safety and performance standards:

| Challenge | Solution |

|---|---|

| High Customization Costs | Use Jianyun Cable’s flexible OEM services with low MOQs (e.g., 500 m). |

| Regulatory Variations | Select dual-certified cables (e.g., TUV/IEC) to cover multiple markets. |

| Quality Assurance | Request batch test reports and factory audits (e.g., SGS). |

| Delivery Delays | Partner with manufacturers like Jianyun Cable offering DHL/FedEx logistics. |

| Technical Mismatches | Collaborate on design phase for tailored specs (e.g., 3.4 mm insulation for 6/10 kV). |

OEM/ODM solutions for medium voltage power cable projects provide customization, cost-effectiveness, and compliance, enabling tailored cables for industrial and utility applications. By following the OEM/ODM process—from defining requirements to delivery—and ensuring certifications like IEC 60502-2 and TUV, buyers can achieve reliable performance. Henan Province Jianyun Cable Co., Ltd. exemplifies a trusted partner, offering TUV-certified, customized MV cables with robust quality control. Addressing challenges like costs and compliance through strategic partnerships ensures successful project outcomes and a cable lifespan of 25–30 years.

NA2XS(f)2Y 6/10KV 12/20KV 120 150 185 240 300MM2 Single Conductor Xlpe Insulated

Grounding Cable 3 Core 95mm2 150mm2 240mm2 Aluminum High Voltage Cable

5x35mm 5x25mm Low Voltage Power Cable With PVC Sheath Copper Conductor XLPE Insu

A medium voltage three core armoured power cable is designed for the reliable tr