Medium Voltage Power Cable Applications in Industrial Projects

Time: 2025-09-22 06:26:37

Source: Henan Province Jianyun Cable Co., Ltd.

Medium voltage (MV) power cables, typically rated from 1 kV to 35 kV per IEC 60038, are critical for efficient and reliable power distribution in industrial projects. These cables bridge the gap between low voltage (LV) and high voltage (HV) systems, serving applications in manufacturing plants, mining operations, oil and gas facilities, and renewable energy installations. This guide explores the applications, specifications, and selection criteria for MV power cables in industrial settings, with references to high-quality products from Henan Province Jianyun Cable Co., Ltd., presented in a formal and structured manner as of September 2025.

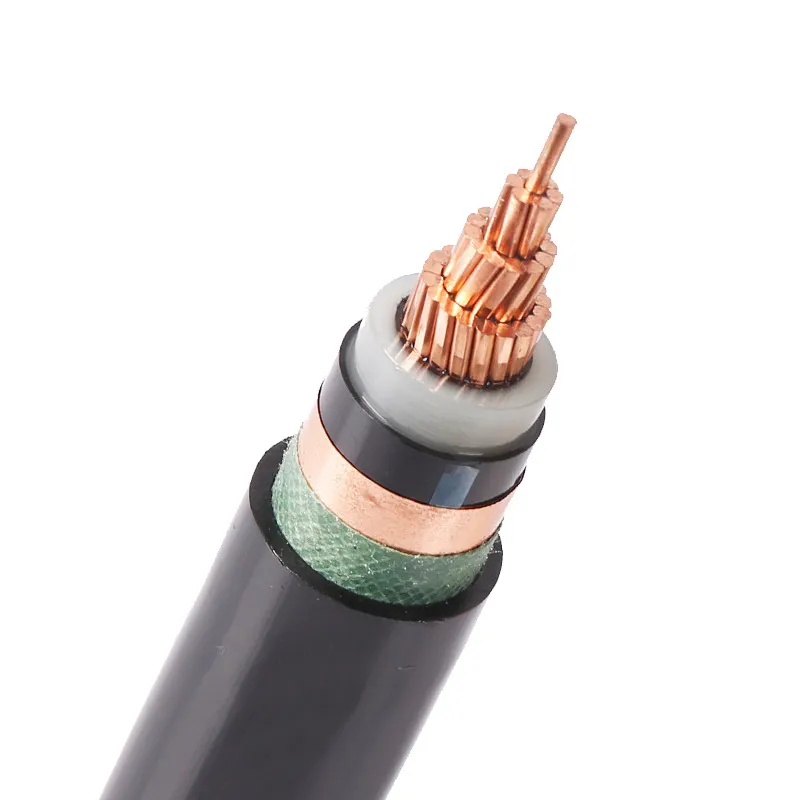

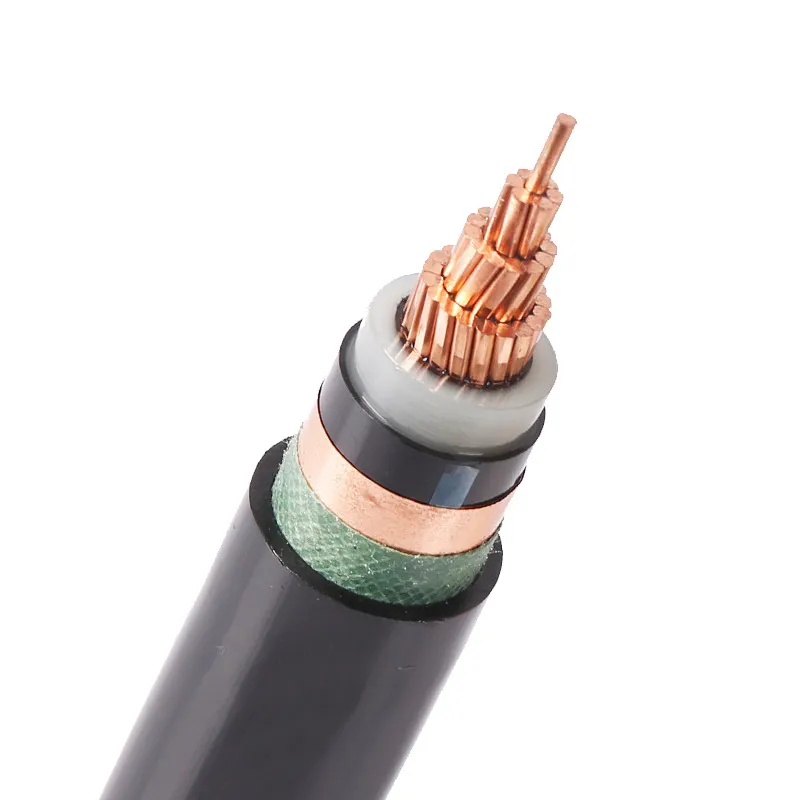

1. Overview of Medium Voltage Power Cables

Medium voltage power cables are designed to transmit electrical power at voltages between 1 kV and 35 kV, making them suitable for industrial applications requiring higher power than LV systems but shorter distances than HV transmission lines. They feature robust insulation, shielding, and often armoring to withstand electrical stress, mechanical loads, and environmental conditions. MV cables are critical for powering heavy machinery, connecting substations, and supporting renewable energy grids. Manufacturers like Henan Province Jianyun Cable Co., Ltd. provide TUV- and CCC-certified MV cables, ensuring compliance and reliability for industrial projects.

2. Key Applications in Industrial Projects

MV power cables are used in various industrial settings due to their ability to handle high power loads and operate in demanding environments. Key applications include:

2.1. Manufacturing Plants

-

Purpose: Powering heavy machinery (e.g., CNC machines, presses) and facility-wide distribution systems.

-

Voltage Range: 3.3 kV to 11 kV.

-

Cable Type: Multi-core XLPE-insulated, steel wire armored (SWA) cables for underground or direct burial.

-

Example: Jianyun Cable’s 11 kV XLPE-insulated, SWA-armored cable for factory power distribution.

2.2. Mining Operations

-

Purpose: Supplying power to underground equipment (e.g., drills, conveyors) and surface facilities.

-

Voltage Range: 6 kV to 15 kV.

-

Cable Type: Armored, PUR-sheathed cables for abrasion and chemical resistance.

-

Example: Jianyun Cable’s 6 kV PUR-sheathed, SWA-armored cable for mining equipment.

2.3. Oil and Gas Facilities

-

Purpose: Powering pumps, compressors, and offshore platforms.

-

Voltage Range: 11 kV to 33 kV.

-

Cable Type: EPR-insulated, lead-sheathed cables for chemical and moisture resistance.

-

Example: Jianyun Cable’s 33 kV EPR-insulated cable for offshore oil platforms.

2.4. Renewable Energy Installations

-

Purpose: Connecting solar farms or wind turbines to the grid.

-

Voltage Range: 11 kV to 35 kV.

-

Cable Type: XLPE-insulated, UV-resistant cables with optional armoring.

-

Example: Jianyun Cable’s 35 kV XLPE-insulated cable for solar farm grid integration.

2.5. Infrastructure Projects

-

Purpose: Powering airport runways, industrial parks, or data centers.

-

Voltage Range: 5 kV to 15 kV.

-

Cable Type: LSZH-sheathed cables for fire safety; armored for underground use.

-

Example: Jianyun Cable’s 5 kV LSZH-armored cable for airport lighting systems.

3. Technical Specifications and Standards

MV power cables must meet rigorous technical requirements to ensure safety, reliability, and performance in industrial environments:

-

Conductor:

-

Material: Copper or aluminum, typically stranded (Class 2 per IEC 60228) for flexibility and current capacity.

-

Resistance: <4.61 Ω/km for 4 mm² copper to minimize voltage drop (<1.5%).

-

Cross-Section: 25–400 mm² for typical MV applications.

-

Insulation:

-

Materials: XLPE (90°C) or EPR for high dielectric strength (≥20 kV/mm).

-

Thickness: 2.5–8 mm depending on voltage (e.g., 3.4 mm for 11 kV per IEC 60502-2).

-

Shielding:

-

Copper tape or wire to manage electric fields and ensure safety.

-

Mandatory for MV cables to prevent partial discharge (<10 pC).

-

Sheathing and Armoring:

-

Sheathing: PVC, PE, LSZH, or PUR for environmental resistance.

-

Armoring: Steel wire (SWA) or steel tape for mechanical protection in underground or high-impact areas.

-

Voltage Rating:

-

1 kV to 35 kV, commonly 3.3 kV, 6 kV, 11 kV, 15 kV, or 33 kV.

-

Standards:

-

IEC 60502-2: MV power cables (6–30 kV).

-

IEC 60038: Voltage classification.

-

IEC 60332-3: Flame-retardant properties for bundled cables.

-

IEC 60754-1/IEC 61034: LSZH requirements for low smoke and toxicity.

-

RoHS/REACH: Restrictions on hazardous substances.

-

Certifications: Jianyun Cable provides TUV, CCC, and ISO 9001-certified MV cables, ensuring global compliance.

|

Specification

|

Details

|

|

Conductor

|

Copper/aluminum, Class 2, 25–400 mm², <4.61 Ω/km for 4 mm² copper.

|

|

Insulation

|

XLPE or EPR, 2.5–8 mm, ≥20 kV/mm dielectric strength.

|

|

Shielding

|

Copper tape/wire, <10 pC partial discharge.

|

|

Sheathing

|

PVC, PE, LSZH, or PUR; SWA or steel tape armoring.

|

|

Voltage Rating

|

1–35 kV (e.g., 3.3 kV, 11 kV, 33 kV).

|

|

Standards

|

IEC 60502-2, IEC 60038, IEC 60332-3, IEC 60754-1.

|

4. Selection Criteria for Industrial Applications

Selecting the appropriate MV power cable for industrial projects requires careful evaluation of several factors:

-

Electrical Requirements:

-

Calculate load (e.g., 200 A for heavy machinery) and select conductor size (e.g., 50 mm² for 11 kV) using IEC 60364 sizing charts.

-

Ensure voltage rating matches system requirements (e.g., 11 kV for manufacturing plants).

-

Environmental Conditions:

-

Use LSZH cables for indoor or confined spaces (e.g., data centers) per IEC 60754-1.

-

Choose PUR or PE sheathing for chemical resistance in mining or oil/gas environments.

-

Select UV-resistant XLPE for outdoor renewable energy installations.

-

Installation Needs:

-

Use SWA-armored cables for underground or high-impact areas; maintain 6–10D bending radius.

-

Ensure proper jointing and termination (e.g., heat-shrink or cold-shrink kits) for reliability.

-

Safety and Compliance:

-

Verify compliance with IEC 60502-2 and regional standards (e.g., G-Mark for GCC markets).

-

Request TUV, UL, or CCC certifications via official databases (e.g., TUV Certipedia).

-

Supplier Reliability:

-

Partner with manufacturers like Jianyun Cable, offering TUV-certified MV cables with proven performance (e.g., showcased at Elektro 2025 in Moscow).

-

Request batch-specific test reports (e.g., insulation resistance >1000 MΩ/km) and factory audits (e.g., SGS).

5. Challenges and Solutions

|

Challenge

|

Solution

|

|

Incorrect Voltage Rating

|

Match cable rating (e.g., 11 kV) to system requirements using IEC 60038.

|

|

Overheating

|

Select appropriately sized conductors (e.g., 50 mm² for 200 A) and apply derating (e.g., 0.91 at 40°C per IEC 60364).

|

|

Counterfeit Products

|

Source from Jianyun Cable with TUV/CCC certifications; verify via official databases.

|

|

Installation Complexity

|

Use SWA-armored cables for mechanical protection; ensure proper jointing and 6–10D bending radius.

|

|

Environmental Damage

|

Choose PUR or LSZH sheathing for chemical or fire safety requirements; use conduits for added protection.

|

6. Conclusion

Medium voltage power cables (1–35 kV) are indispensable for industrial projects, powering manufacturing plants, mining operations, oil and gas facilities, renewable energy installations, and infrastructure like airports and data centers. Their robust construction, including XLPE or EPR insulation, copper shielding, and SWA armoring, ensures reliability in demanding environments. Compliance with standards like IEC 60502-2, IEC 60038, and IEC 60332-3 guarantees safety and performance. Henan Province Jianyun Cable Co., Ltd. offers TUV- and CCC-certified MV cables, providing tailored solutions for industrial applications. By evaluating electrical, environmental, and installation requirements, and partnering with trusted suppliers, industrial projects can achieve safe, efficient, and durable power distribution systems lasting 20–30 years.