Time: 2025-08-06 16:30:52 Source: Henan Province Jianyun Cable Co., Ltd.

Flame retardant cables are engineered to resist the spread of fire and maintain functionality under fire conditions, making them critical for industrial safety in environments where fire risks are significant. These cables are designed to meet stringent fire safety standards, ensuring minimal flame propagation and reduced emission of hazardous substances. This guide explains how flame retardant cables work, their key features, and their applications in industrial settings, presented in a formal and structured manner.

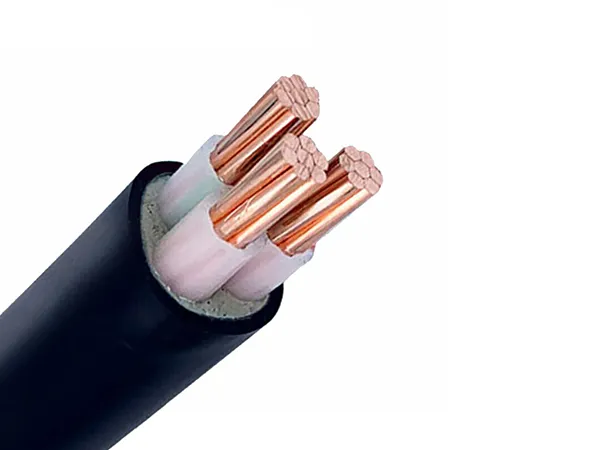

Flame retardant cables are electrical cables designed to resist ignition, limit flame spread, and reduce smoke and toxic gas emissions during a fire. They are typically used in power distribution, control systems, and communication networks in industrial environments such as factories, chemical plants, and oil refineries. These cables feature specialized insulation and sheathing materials, such as flame-retardant polyvinyl chloride (PVC), cross-linked polyethylene (XLPE), or low-smoke zero-halogen (LSZH) compounds, and comply with standards like IEC 60332-1 or UL 1666. They are essential for ensuring safety and maintaining critical operations during fire incidents.

| Feature | Details |

|---|---|

| Purpose | Resist ignition, limit flame spread, reduce smoke/toxins |

| Materials | Flame-retardant PVC, XLPE, LSZH |

| Voltage Range | 0.6/1 kV to 26/45 kV |

| Standards | IEC 60332-1, UL 1666, EN 50266 |

Flame retardant cables are designed with materials and construction techniques that inhibit combustion and limit fire propagation. Their functionality relies on the following mechanisms:

| Mechanism | Function |

|---|---|

| Flame-Retardant Materials | Increase ignition resistance, reduce toxicity |

| Flame Propagation | Self-extinguish, limit spread (IEC 60332) |

| Low Smoke | Improve visibility (EN 61034) |

| Circuit Integrity | Maintain function in fire (IEC 60331) |

Flame retardant cables are characterized by specific features and compliance with international standards:

| Feature/Standard | Details |

|---|---|

| Ignition Resistance | Resists burning, self-extinguishing |

| Low Smoke/Toxicity | LSZH materials, minimal emissions |

| Thermal Stability | 90°C (XLPE), 250°C short-circuit |

| Standards | IEC 60332, IEC 60331, EN 61034 |

Flame retardant cables are critical in industrial settings where fire risks are high, ensuring safety and operational continuity:

| Application | Cable Features |

|---|---|

| Chemical Plants | LSZH, flame-retardant |

| Oil Refineries | Armoured, XLPE-insulated |

| Manufacturing | 0.6/1 kV to 26/45 kV, flame-retardant |

| Emergency Systems | IEC 60331 circuit integrity |

Flame retardant cables differ significantly from standard cables (e.g., non-treated PVC or PE-insulated cables):

| Property | Flame Retardant | Standard |

|---|---|---|

| Flame Propagation | Limited (IEC 60332) | Rapid spread |

| Smoke/Toxicity | Low (LSZH) | High, toxic (PVC) |

| Circuit Integrity | Maintained (IEC 60331) | Not maintained |

| Cost | Higher | Lower |

| Challenge | Solution |

|---|---|

| Higher Cost | Use standard cables where fire risk is low, justify flame-retardant cables for safety-critical areas |

| Complex Installation | Train installers on handling, use proper termination kits |

| Material Selection | Choose LSZH for confined spaces, flame-retardant PVC for cost-sensitive applications |

| Compliance Verification | Request test reports, ensure IEC 60332/60331 compliance |

Flame retardant cables play a vital role in industrial safety by resisting ignition, limiting flame spread, and reducing smoke and toxic emissions during fires. Their specialized materials and compliance with standards like IEC 60332 and IEC 60331 make them essential for high-risk environments such as chemical plants, oil refineries, and data centers. While they are more expensive than standard cables, their ability to enhance safety, maintain circuit integrity, and support evacuation and firefighting justifies their use. By selecting appropriate flame-retardant materials (e.g., LSZH for confined spaces) and ensuring proper installation, industries can achieve reliable and safe power distribution systems with a lifespan of 25–30 years.

NA2XS(f)2Y 6/10KV 12/20KV 120 150 185 240 300MM2 Single Conductor Xlpe Insulated

Grounding Cable 3 Core 95mm2 150mm2 240mm2 Aluminum High Voltage Cable

5x35mm 5x25mm Low Voltage Power Cable With PVC Sheath Copper Conductor XLPE Insu

A medium voltage three core armoured power cable is designed for the reliable tr