Time: 2025-12-04 03:33:07 Source: Henan Province Jianyun Cable Co., Ltd.

Saudi Arabia's vast deserts, with ambient temperatures often exceeding 50°C, pose severe risks to electrical cables, accelerating insulation degradation, cracking, and short circuits. The SASO/IECstandards, issued by the Saudi Standards, Metrology and Quality Organization (SASO), adapt international IEC norms to these extreme conditions, ensuring cables withstand heat without compromising safety. Based on IEC 60227 series for PVC-insulated cables and aligned with SBC 401 (Saudi Building Code), these standards emphasize derating, material selection, and testing for longevity. This guide explores prevention strategies, vital for engineers, contractors, and exporters in the Kingdom's $15B+ electrical sector amid Vision 2030's infrastructure boom.

SASO/IEC standards, such as SASO IEC 60227-1:2007 (PVC cables up to 450/750V) and SASO IEC 60227-2:2003 (test methods), vary IEC baselines to suit Saudi conditions, including higher ambient temperatures. They cover design, materials, and verification for low-voltage installations up to 1000V AC/1500V DC. Legally enforced via the Electrical Appliances Safety Law and SPSP (Saudi Product Safety Programme), compliance requires SASO certification (G-Mark or IECEE CB Scheme). 2025 updates focus on renewables and desert resilience, mandating heat-specific tests like accelerated aging at 100°C.

In Middle East deserts, cables face thermal cycling (day highs 50°C+, night drops), UV exposure, sand abrasion, and humidity spikes, leading to PVC/XLPE insulation hardening, cracking, and conductivity loss. Aging shortens lifespan from 30+ years to under 10, risking fires and outages. SASO/IEC addresses this via tailored derating (e.g., 20-30% capacity reduction at 40°C) and material specs for 90°C-rated conductors, preventing oxidation and migration in silica-rich sands.

SASO/IEC mandates multi-layered defenses: (1) Heat-resistant insulations like XLPE (90°C continuous) over PVC (70°C); (2) Derating factors from IEC 60364-5-52 tables, adjusted for 40-50°C ambients; (3) UV-stabilized sheaths and metallic armoring for burial; (4) Accelerated aging tests (IEC 60227-2: 7 days at 100°C); (5) Conduit enclosures to shield from direct sun/sand. These extend life by 50%, aligning with SBC 401's safety clauses.

Sizing per SASO IEC 60227 considers base ampacity, derated for heat (K=0.82 at 40°C, 0.71 at 50°C), voltage drop (max 5%), and grouping. Use copper for efficiency; min 1.5 mm² for lighting. Tables from IEC 60364 adapted for desert use.

| Circuit Type | Cable Size (mm²) | Base Ampacity (30°C) | Derated (50°C) | Typical Use |

|---|---|---|---|---|

| Lighting | 1.5 | 18 A | 12.8 A | Indoor fixtures |

| Socket-Outlets | 2.5 | 25 A | 17.8 A | General outlets |

| Air Conditioning | 4.0 | 34 A | 24.1 A | Cooling units |

| Power Feeders | 6.0 | 44 A | 31.2 A | Submains |

| Earth (PE) | Min 2.5 | N/A | N/A | Grounding |

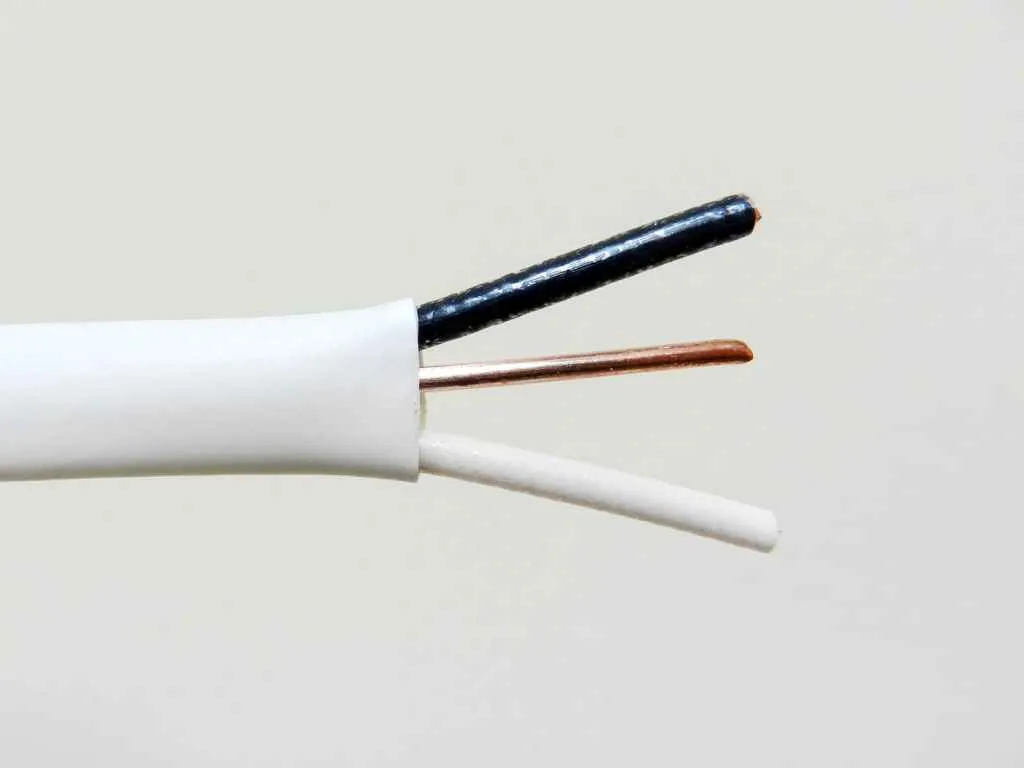

Per SASO IEC 60446: Brown (phase), blue (neutral), green/yellow (PE). Multi-phase: Brown (L1), black (L2), grey (L3). Full-length coloring; heat-resistant markings ensure legibility in dusty environments.

SBC 401/SASO requires conduits/PVC ducts for surface runs, buried cables 600 mm deep with sand bedding. Derate for grouped cables; RCDs (30 mA) for sockets. Desert adaptations: Elevated supports to avoid sand burial, UV-rated sheaths for exposed runs. 2025: Enhanced solar PV cabling per SASO IEC 62548.

SASO IEC 60332 mandates flame-retardant cables; low-smoke halogen-free (LSHF) for public spaces. Heat aging tests (IEC 60227-2) simulate desert exposure, ensuring no cracking post-100°C cycles. Armored SWA cables prevent fire spread in buried lines.

SASO/IEC's heat-focused strategies – from XLPE materials to rigorous derating – armor cables against desert fury, ensuring reliable power in Saudi's scorching sands. As NEOM and Red Sea projects rise, these standards fuel safe, sustainable growth. Prioritize them for enduring performance.

Need SASO/IEC-compliant heat-resistant cables? Contact Henan Province Jianyun Cable Co., Ltd. for tailored solutions and quotes.

CE Certification 450/750v H07VVF Flexible Copper PVC Insulated Ac Cable 3*2.5 Mm

low voltage copper conductor PVC insulation underground BV BVR cable for industr

PVC electric wires are one of the most widely used electrical conductors in resi

H07V-U wire is a flexible, low voltage electrical wire commonly used in industri