Time: 2025-10-10 04:02:50 Source: Henan Province Jianyun Cable Co., Ltd.

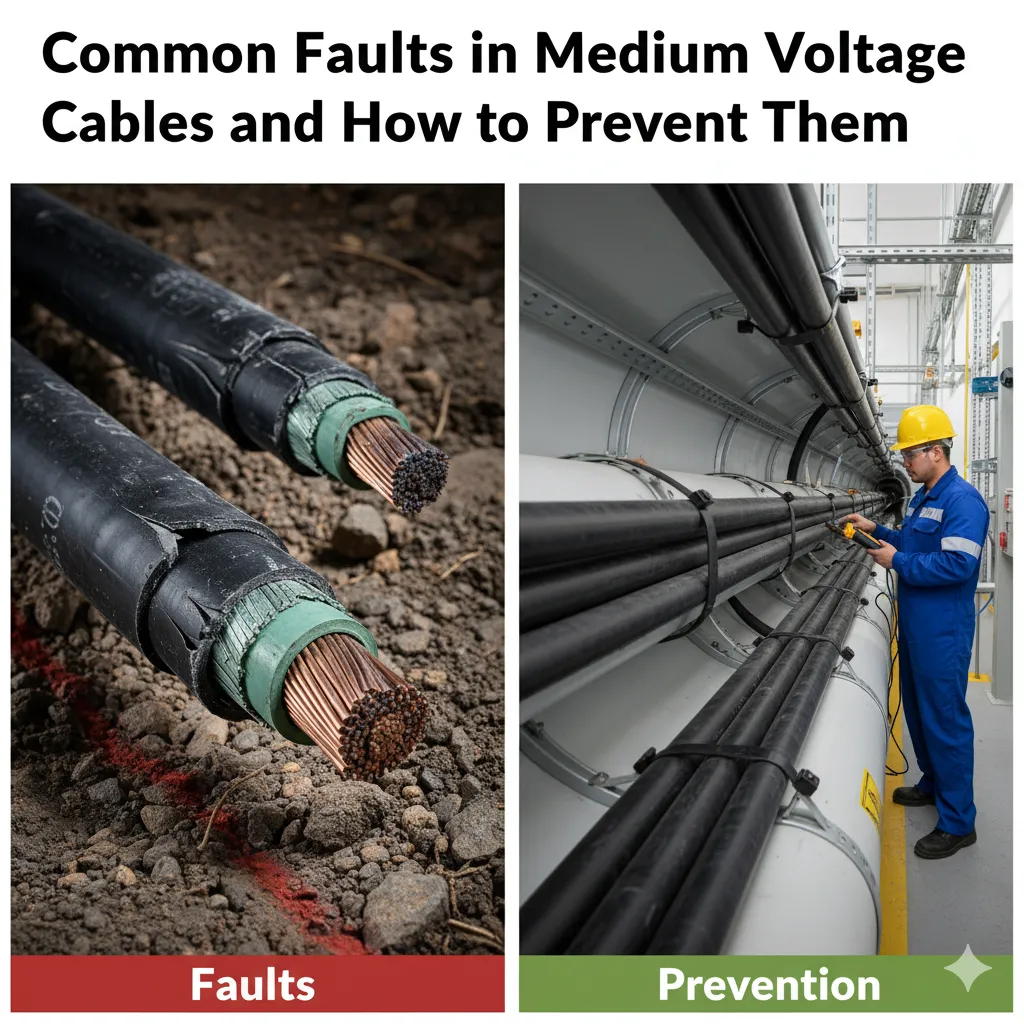

Medium voltage (MV) power cables, rated from 6 kV to 35 kV per IEC 60038, are susceptible to faults that can lead to system failures, safety hazards, or costly downtime. Common faults arise from insulation issues, mechanical damage, or installation errors. Understanding these faults and implementing preventive measures is essential for ensuring cable reliability and a lifespan of 25–30 years.

MV cable faults occur due to defects in insulation, conductors, or joints, often resulting from environmental stress, improper installation, or manufacturing issues. Faults can cause insulation breakdown, partial discharge, or short circuits, leading to outages or fires. Early detection and prevention, guided by standards like IEC 60502-2 and IEEE 400, are crucial. Jianyun Cable’s TUV-certified MV cables minimize faults through robust XLPE insulation and shielding, ensuring reliability in industrial applications.

The most common MV cable faults include:

Preventing MV cable faults requires proactive measures:

| Fault | Cause | Prevention |

|---|---|---|

| Insulation Breakdown | Thermal overload, moisture | XLPE insulation, water-blocking tapes, derating. |

| Partial Discharge | Insulation voids, poor jointing | Proper jointing kits, PD testing (<10 pC). |

| Joint Failures | Loose connections, corrosion | Heat/cold-shrink kits, anti-corrosion compounds. |

| Mechanical Damage | Impact, crushing | SWA armoring, conduits for protection. |

| Corrosion | Moisture, chemicals | Galvanized SWA, PUR sheathing, sealed ends. |

Regular testing detects potential faults early:

| Test | Details |

|---|---|

| Insulation Resistance | >1000 MΩ/km at 20°C |

| Partial Discharge | <10 pC at 1.73 × U₀ |

| TDR | Locate faults |

| Thermal Imaging | Detect hotspots |

| Sheath Integrity | 5 kV DC test |

MV cables must comply with international standards to ensure fault prevention:

| Standard | Details |

|---|---|

| IEC 60502-2 | MV cable construction, testing |

| IEEE 400 | Field testing guidelines |

| IEC 60332-3 | Flame-retardant properties |

| IEC 60038 | Voltage classification |

| Challenge | Solution |

|---|---|

| Detecting Early Faults | Implement PD monitoring and insulation tests; use Jianyun Cable’s high-quality XLPE cables. |

| Installation Errors | Train personnel on jointing; maintain bending radii (6–10D). |

| Environmental Exposure | Use SWA-armored cables; apply anti-corrosion coatings. |

| Counterfeit Cables | Source from Jianyun Cable with TUV/CCC certifications; verify via databases. |

| Regulatory Non-Compliance | Confirm compliance with IEC 60502-2 and regional standards (e.g., G-Mark for GCC). |

Common faults in medium voltage cables—insulation breakdown, partial discharge, joint failures, mechanical damage, and corrosion—can be prevented through proper cable selection (e.g., XLPE insulation, SWA armoring), thermal management, and environmental protections. Regular testing (e.g., PD, insulation resistance) and compliance with standards like IEC 60502-2 ensure long-term reliability. Henan Province Jianyun Cable Co., Ltd. offers TUV-certified MV cables designed to minimize faults, providing robust solutions for industrial applications. By implementing these strategies, users can achieve safe, efficient power systems with a lifespan of 25–30 years.

NA2XS(f)2Y 6/10KV 12/20KV 120 150 185 240 300MM2 Single Conductor Xlpe Insulated

Grounding Cable 3 Core 95mm2 150mm2 240mm2 Aluminum High Voltage Cable

5x35mm 5x25mm Low Voltage Power Cable With PVC Sheath Copper Conductor XLPE Insu

A medium voltage three core armoured power cable is designed for the reliable tr