5 Key Differences Between Low and Medium Voltage Power Cables

Time: 2025-07-30 05:36:47

Source: Henan Province Jianyun Cable Co., Ltd.

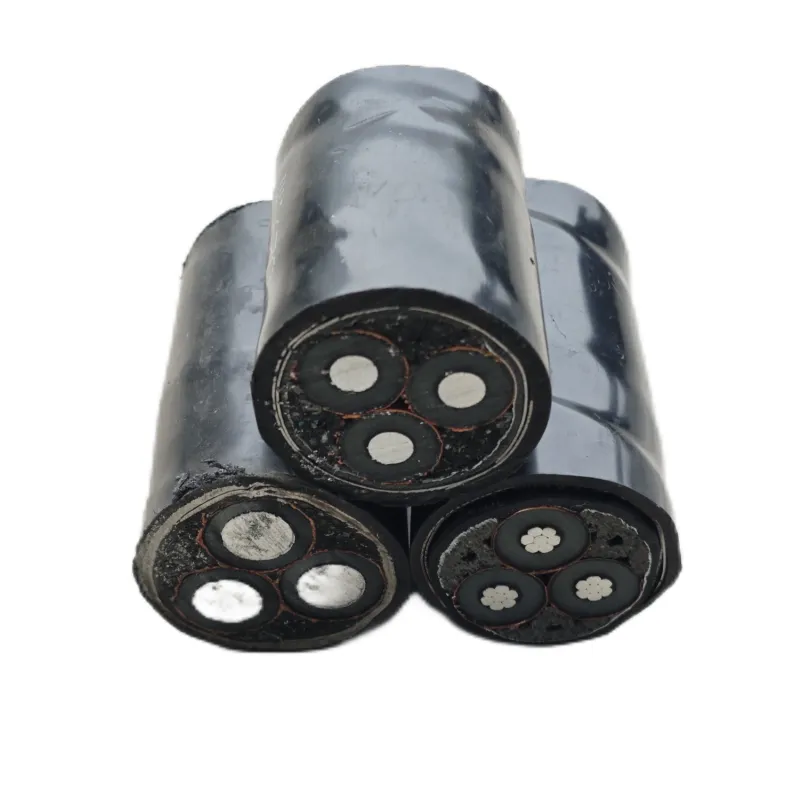

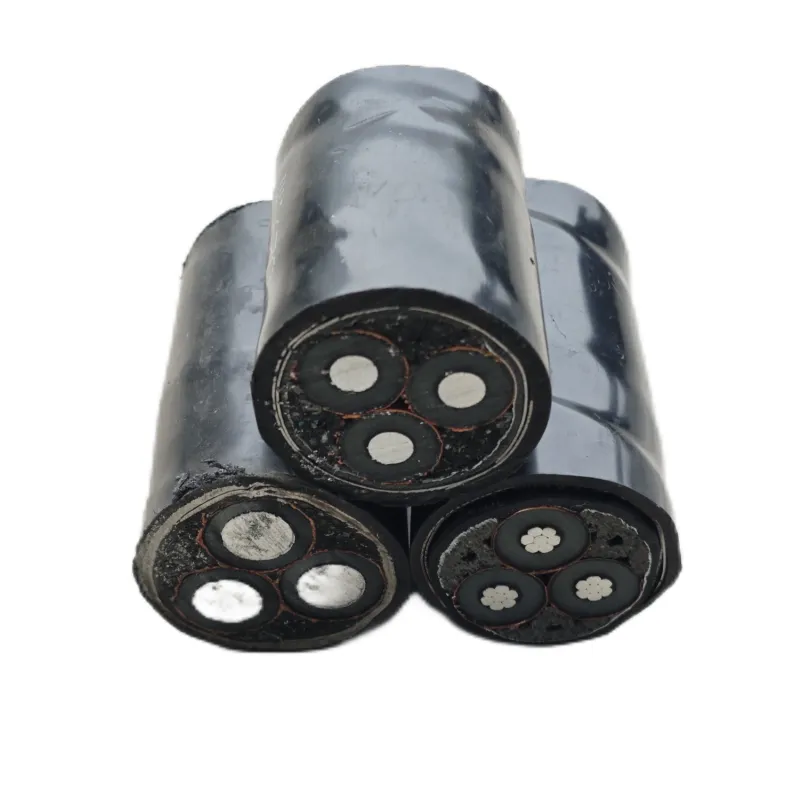

Low voltage (LV) and medium voltage (MV) power cables are critical components in electrical distribution systems, each designed for specific voltage ranges and applications. LV cables, typically rated at 0.6/1 kV, are used for residential, commercial, and light industrial power distribution, while MV cables, rated from 1 kV to 35 kV, serve industrial, utility, and renewable energy applications. Understanding their differences is essential for selecting the appropriate cable for a project, ensuring safety, efficiency, and compliance with standards. This document outlines five key differences between LV and MV power cables, presented in a formal and structured manner.

Table of Contents

1. Voltage Rating and Application

-

Low Voltage Cables (LV): Rated at 0.6/1 kV, designed for applications up to 1000 V, such as residential wiring, commercial building power distribution, street lighting, and small industrial equipment. They handle lower currents and are suitable for short to medium cable runs with minimal voltage drop.

-

Medium Voltage Cables (MV): Rated from 1 kV to 35 kV (e.g., 6/10 kV, 12/20 kV), used for higher power applications like urban power grids, industrial plants, renewable energy farms (wind/solar), and substations. They support longer distances and higher current loads.

-

Impact: LV cables are simpler and more cost-effective for low-power needs, while MV cables are essential for high-power, long-distance transmission requiring robust design.

2. Insulation and Dielectric Strength

-

Low Voltage Cables: Typically use polyvinyl chloride (PVC) or cross-linked polyethylene (XLPE) insulation, with lower dielectric strength requirements due to the lower voltage. Insulation thickness is smaller (e.g., 0.7–1.2 mm for 1 kV), sufficient for basic environmental and electrical protection.

-

Medium Voltage Cables: Require advanced insulation materials like XLPE or ethylene propylene rubber (EPR) with higher dielectric strength to withstand voltages up to 35 kV. Insulation thickness is significantly greater (e.g., 3.4–8 mm for 12/20 kV) to prevent dielectric breakdown.

-

Impact: MV cables demand thicker, higher-quality insulation to ensure safety and reliability under higher electrical stress, increasing material complexity.

3. Construction and Shielding

-

Low Voltage Cables: Simpler construction with copper or aluminum conductors, insulation, and sheathing (PVC, PE, or LSZH). Shielding is often optional, used only in environments with high electromagnetic interference (EMI). Armoring (e.g., steel wire armor) is common for underground or harsh conditions but not always required.

-

Medium Voltage Cables: Complex construction including copper or aluminum conductors, XLPE/EPR insulation, metallic shielding (e.g., copper tape or wire) for EMI protection and fault current paths, and armoring (e.g., steel wire or tape) for mechanical strength. Water-blocking layers are standard for underground or wet environments.

-

Impact: MV cables require additional layers (shielding, armoring) to handle higher voltages and environmental stresses, increasing size and weight compared to LV cables.

4. Installation Complexity

-

Low Voltage Cables: Easier to install due to lighter weight, smaller diameter, and less stringent handling requirements. Can be laid in conduits, trays, or directly buried with minimal specialized equipment. Jointing and termination are simpler, requiring basic connectors.

-

Medium Voltage Cables: Require careful handling due to heavier weight, larger diameter, and sensitivity to insulation damage. Installation involves specialized equipment (e.g., cable pulling winches, rollers) and precise jointing/termination (e.g., heat-shrink or pre-molded kits) to maintain dielectric integrity. Stricter bend radius (10–15 times cable diameter) and grounding requirements apply.

-

Impact: MV cable installation demands skilled personnel, specialized tools, and rigorous testing (e.g., partial discharge tests), increasing complexity and time compared to LV cables.

5. Cost and Maintenance

-

Low Voltage Cables: Lower initial cost due to simpler materials (e.g., PVC insulation) and less complex construction. Maintenance is minimal, with periodic visual inspections and basic electrical tests (e.g., insulation resistance). Service life is typically 15–25 years, depending on conditions.

-

Medium Voltage Cables: Higher initial cost due to advanced materials (e.g., XLPE, shielding, armoring) and manufacturing complexity. Maintenance involves regular testing (e.g., partial discharge, thermal monitoring) to detect insulation degradation or faults, with a longer service life (25–40 years).

-

Impact: MV cables have higher upfront and maintenance costs but offer greater durability and efficiency for critical, high-power applications.

6. Comparison Table

|

Feature

|

Low Voltage Cables (0.6/1 kV)

|

Medium Voltage Cables (1–35 kV)

|

|

Voltage Rating

|

Up to 1 kV

|

1–35 kV

|

|

Applications

|

Residential, commercial, light industrial

|

Industrial, utilities, renewable energy

|

|

Insulation

|

PVC, XLPE (0.7–1.2 mm)

|

XLPE, EPR (3.4–8 mm)

|

|

Construction

|

Simple, optional shielding/armoring

|

Complex, with shielding and armoring

|

|

Installation

|

Easier, basic equipment

|

Complex, specialized equipment

|

|

Cost

|

Lower

|

Higher

|

|

Maintenance

|

Minimal, basic tests

|

Regular, advanced testing

|

|

Standards

|

IEC 60502-1, UL 83, EN 50525

|

IEC 60502-2, UL 1072, IEC 60840

|

7. Conclusion

Low voltage (0.6/1 kV) and medium voltage (1–35 kV) power cables serve distinct purposes, with key differences in voltage rating, insulation, construction, installation complexity, and cost. LV cables are cost-effective and simpler, ideal for residential and light industrial applications, while MV cables, with advanced insulation, shielding, and armoring, are suited for high-power, long-distance, and industrial applications. By understanding these differences, project managers can select the appropriate cable type, ensuring safety, efficiency, and compliance with standards like IEC 60502 and UL 1072 for their specific project requirements.