Understanding LSOH Cables: Safety and Applications

Time: 2025-05-08 06:48:23

Source: Henan Province Jianyun Cable Co., Ltd.

What Are LSOH Cables?

Low Smoke Zero Halogen (LSOH) cables, also referred to as LSZH, LS0H, LSFH, or OHLS, are specialized electrical cables designed to enhance safety during fire events. Unlike traditional cables, LSOH cables emit minimal smoke and no halogen gases when exposed to flames, reducing risks of toxic inhalation and equipment corrosion. These cables are critical in environments where fire safety is paramount, such as public buildings, transportation systems, and confined spaces. Their halogen-free composition makes them an environmentally friendly choice, aligning with modern safety and sustainability standards.

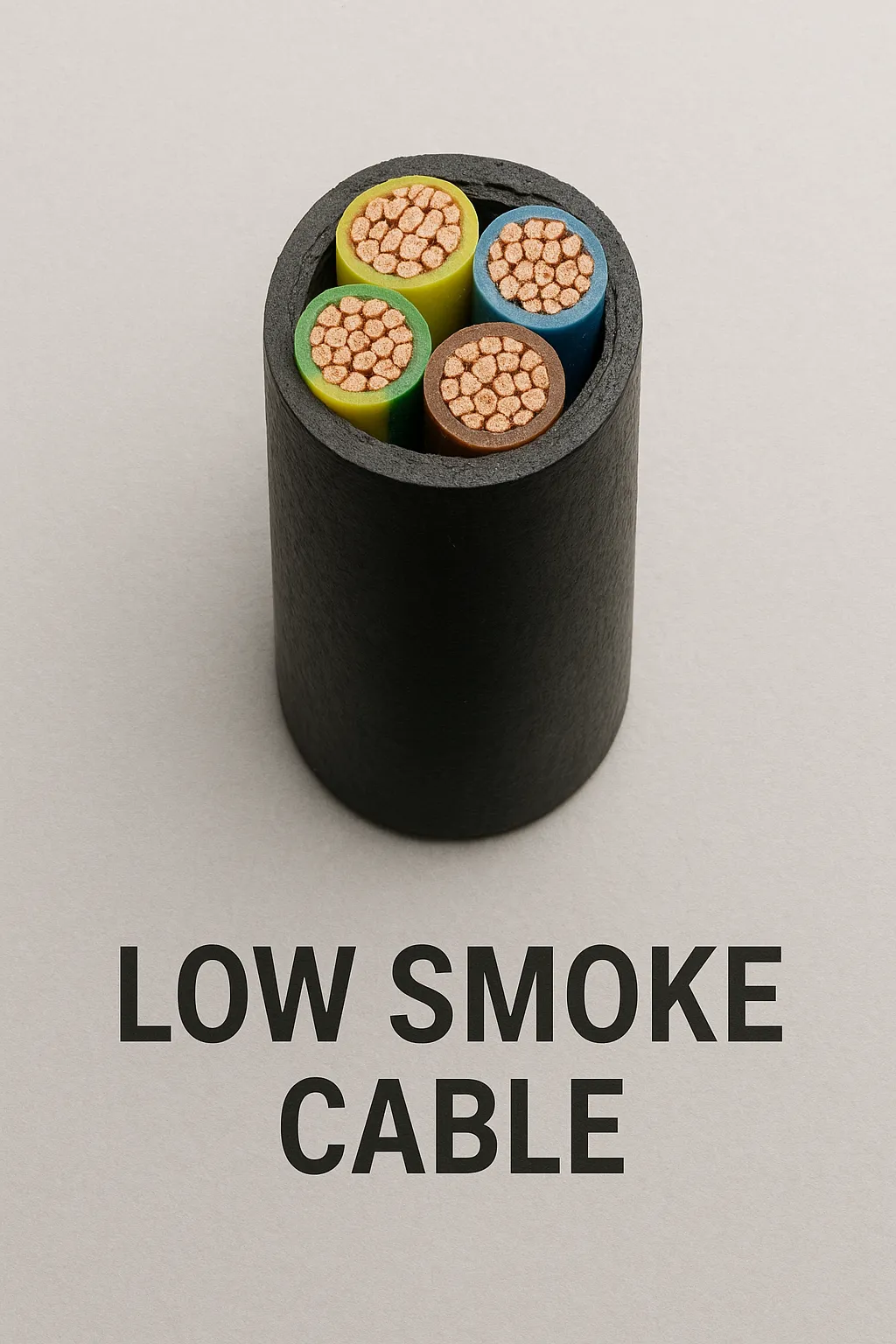

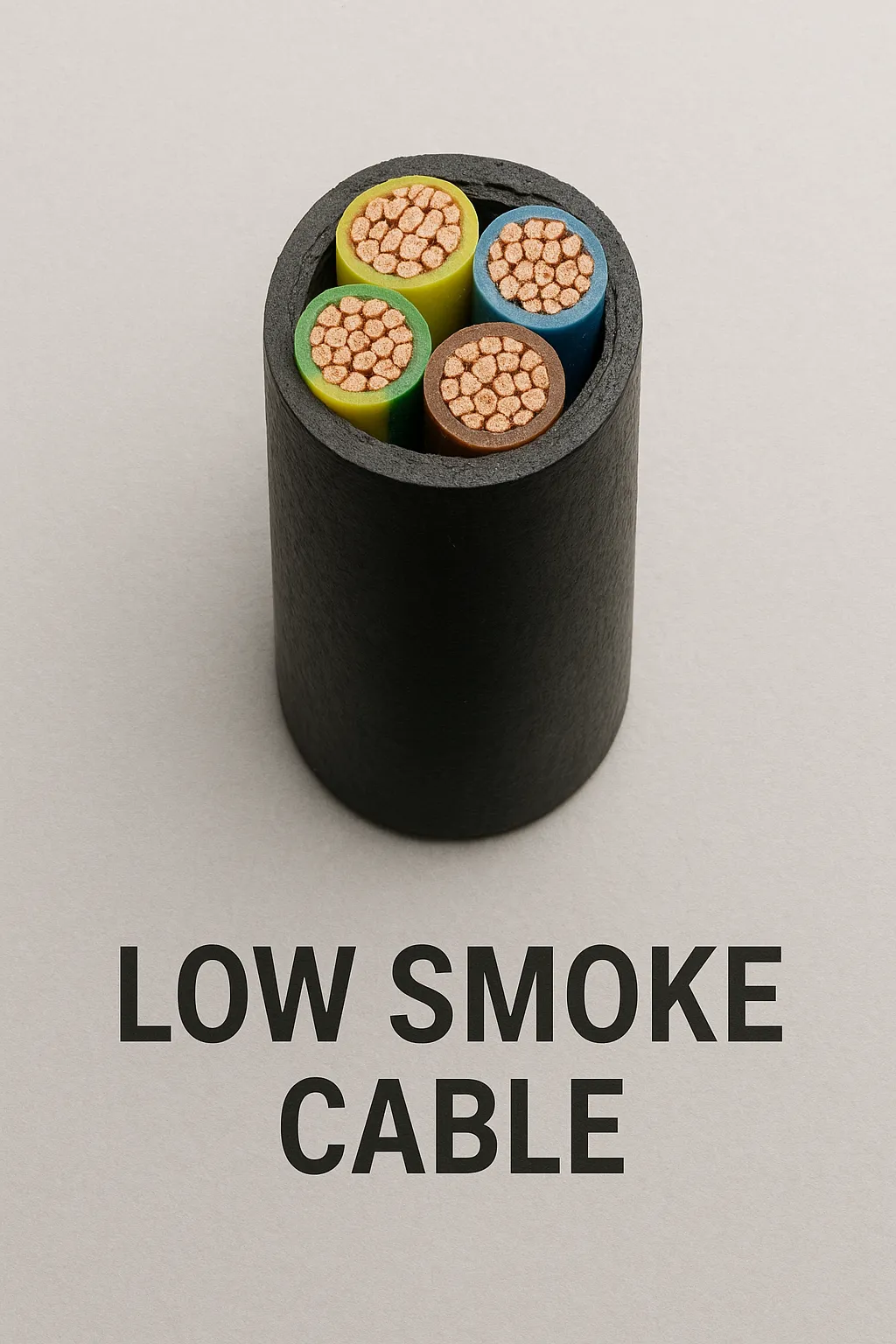

How Are LSOH Cables Constructed?

LSOH cables are engineered with materials that prioritize fire safety and low toxicity:

-

Conductor: Typically stranded or solid copper for conductivity, available in various gauges (e.g., 6 AWG for high-current applications).

-

Insulation: Made from halogen-free thermoplastic or thermoset compounds, such as cross-linked polyolefin or XLPE, which are flame-retardant and produce minimal smoke.

-

Sheath: A halogen-free outer jacket, often polyolefin-based, enhances fire resistance and reduces toxic emissions.

-

Optional Features: Some LSOH cables include armor (e.g., steel wire for underground use) or shielding for electromagnetic interference protection in data applications.

The absence of halogens (e.g., chlorine, bromine) in the insulation and sheath distinguishes LSOH cables from PVC-based cables, ensuring safer performance in fire scenarios.

LSOH vs. PVC Cables: Key Differences

LSOH cables offer significant advantages over traditional polyvinyl chloride (PVC) cables, particularly in fire safety:

-

Smoke Emission: LSOH cables produce very low smoke, improving visibility for evacuation and firefighting. PVC cables release dense, black smoke, obscuring exits.

-

Toxicity: LSOH cables are halogen-free, emitting no toxic gases like hydrogen chloride. PVC cables release corrosive halogen gases, harmful to humans and equipment.

-

Fire Resistance: LSOH cables are flame-retardant, burning slowly to delay fire spread. PVC cables ignite quickly and contribute to fire propagation.

-

Lifespan: LSOH cables have a service life of up to 70 years, compared to 25 years for PVC, reducing replacement costs.

-

Cost: LSOH cables are more(batch) expensive due to specialized materials and manufacturing, while PVC cables are budget-friendly but less safe.

Testing, such as the IEC 61034 smoke density test, confirms LSOH cables maintain over 60% light visibility during combustion, unlike PVC cables.

Single-Core and Multi-Core LSOH Cables

LSOH cables are available in single-core and multi-core configurations, similar to other cable types like THHN or welding cables:

-

Single-Core LSOH: Used for single-circuit applications, such as power delivery in welding systems or lighting circuits. For example, a 6 AWG single-core LSOH cable can handle 55-65 amps, ideal for high-current tasks in confined spaces.

-

Multi-Core LSOH: Common in complex systems, such as three-phase power distribution or control circuits. A 4-core LSOH cable might include three phase conductors and a neutral or ground, used in industrial setups or public infrastructure like subways.

Multi-core LSOH cables are particularly valuable in safety-critical applications, where their low-smoke properties protect dense wiring environments. Unlike TFFN, which is limited to dry locations, LSOH cables are suitable for both dry and wet environments when properly rated.

What Are the Applications of LSOH Cables?

LSOH cables are used in environments where fire safety and minimal toxic emissions are critical:

-

Public Buildings: Hospitals, schools, airports, and shopping centers use LSOH cables to protect occupants during fires.

-

Transportation: Subways, railways, and aircraft rely on LSOH cables to reduce smoke and toxicity in confined spaces.

-

Data Centers: Dense wiring in data centers benefits from LSOH’s low smoke and corrosion resistance, protecting sensitive equipment.

-

Industrial Facilities: Factories and oil/gas plants use LSOH cables for power and control circuits to enhance worker safety.

-

Marine and Military: Ships and submarines use LSOH cables to minimize fire hazards in enclosed environments.

Regulations, such as the EU’s Construction Products Regulation (CPR), often mandate LSOH cables in public spaces, with ratings like B2ca-s1a,d1,a1 for high safety.

LSOH vs. PVC Comparison Table

The following table highlights the key differences between LSOH and PVC cables:

|

Feature

|

LSOH

|

PVC

|

|

Smoke Emission

|

Low (over 60% light visibility)

|

High (dense, black smoke)

|

|

Halogen Content

|

Zero (<0.2% halogens)

|

Contains chlorine

|

|

Toxicity

|

Non-toxic emissions

|

Toxic hydrogen chloride gas

|

|

Fire Resistance

|

Flame-retardant, slow-burning

|

Quick to ignite

|

|

Lifespan

|

Up to 70 years

|

~25 years

|

|

Cost

|

Higher

|

Lower

|

|

Applications

|

Public spaces, confined areas

|

General-purpose, budget projects

|

Note: LSOH ratings are verified by tests like IEC 60754-1 for halogen content and IEC 61034 for smoke density.

Safety and Selection Tips for LSOH Cables

Selecting and installing LSOH cables requires attention to safety and compliance:

-

Choose Certified Cables: Ensure LSOH cables meet standards like IEC 60754 (halogen content <0.2%) and CPR ratings for public spaces.

-

Match Gauge to Load: Use appropriate AWG sizes (e.g., 6 AWG for 55-65 amps) to prevent overheating, similar to THHN or welding cables.

-

Consider Environment: Select LSOH cables rated for wet or UV-exposed areas, unlike TFFN, which is dry-only.

-

Inspect for Damage: Check insulation and sheathing for cuts or abrasions to maintain fire safety.

-

Comply with Regulations: Follow NEC, IEC, or local codes, especially in public infrastructure where LSOH is mandatory.

-

Professional Installation: Hire licensed electricians for complex setups, such as 4-core LSOH cables in three-phase systems.

Regular maintenance ensures long-term reliability, leveraging LSOH’s 70-year lifespan.

Conclusion

LSOH cables are a critical choice for safety-conscious electrical installations, offering low smoke, zero halogen emissions, and superior fire resistance compared to PVC cables. Their single-core and multi-core configurations, such as 4-core cables for three-phase systems, make them versatile for applications from public buildings to industrial facilities. While more expensive, their 70-year lifespan and enhanced safety justify the investment in environments like hospitals, subways, and data centers. By selecting appropriately sized and certified LSOH cables, you can ensure compliance with regulations and protect lives and equipment. Consult a professional electrician to optimize your LSOH cable installations.