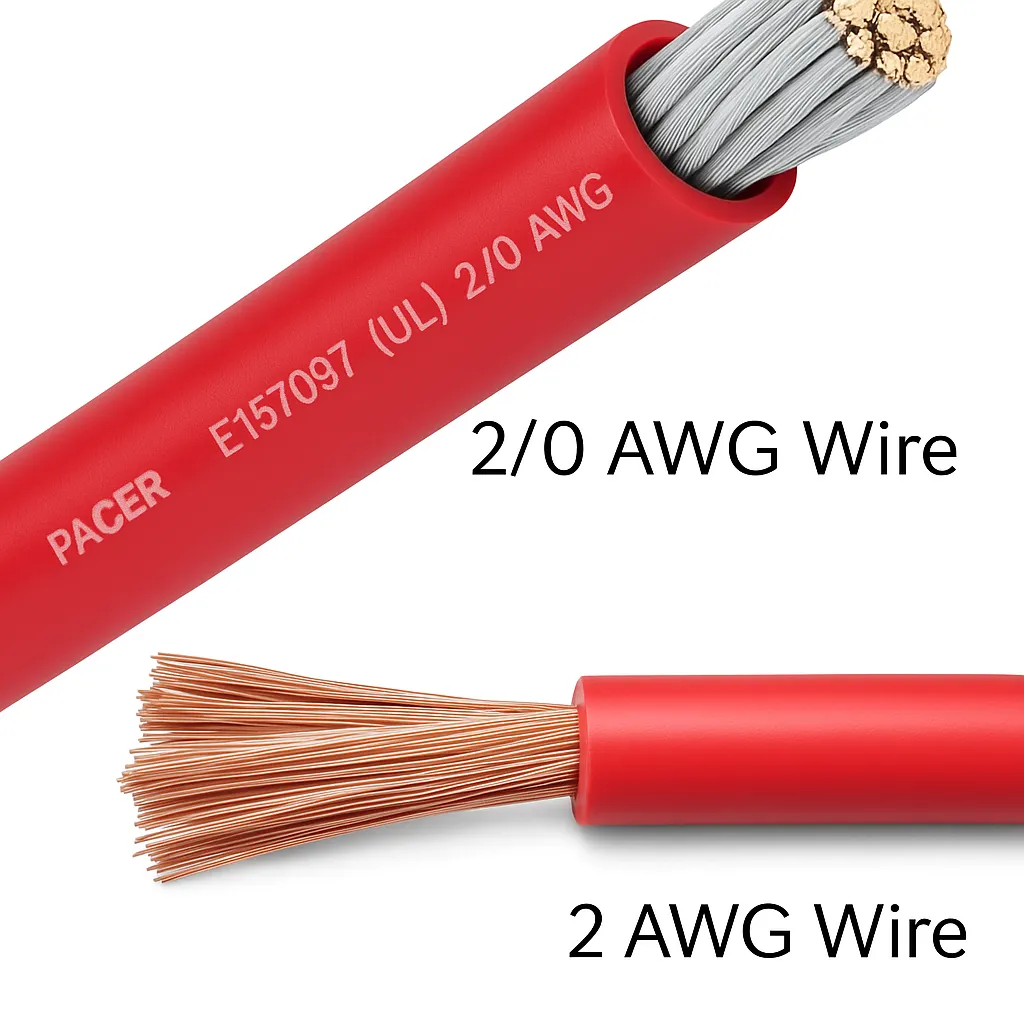

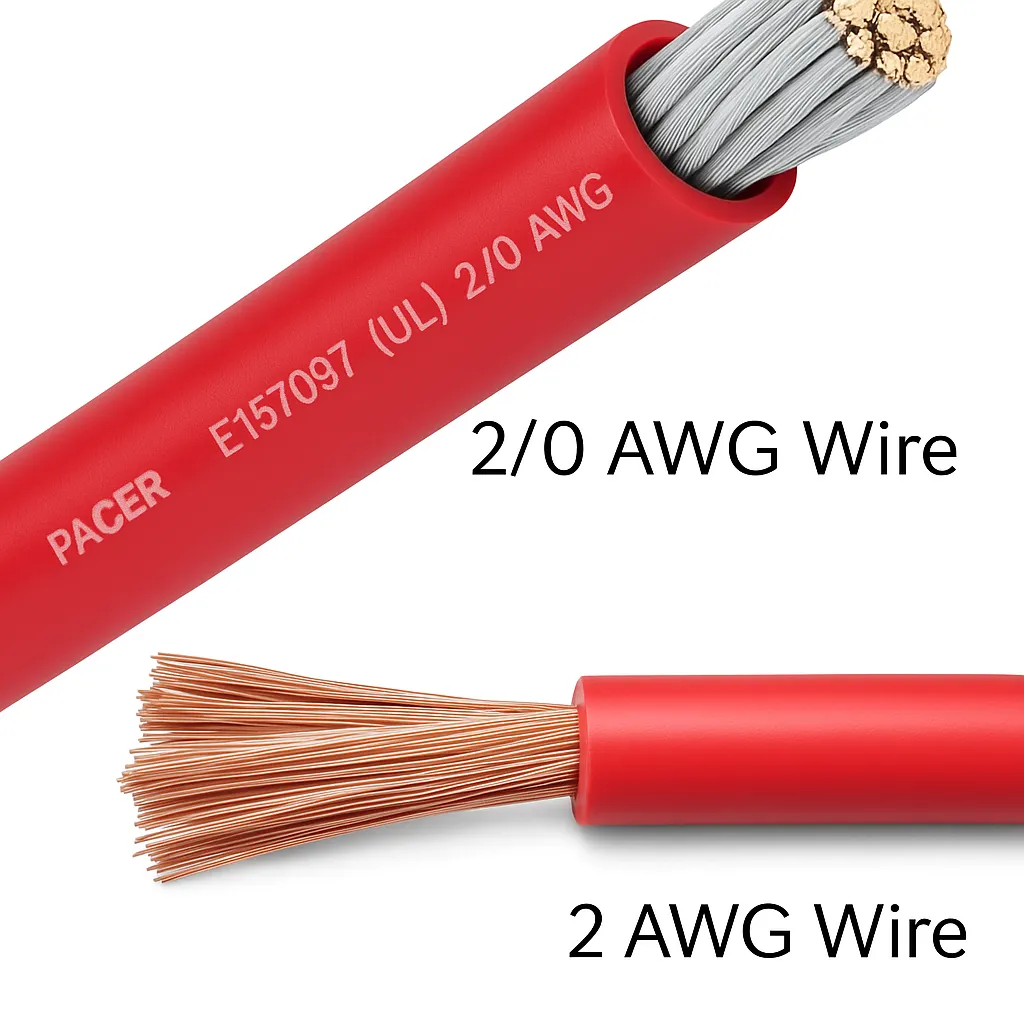

2 AWG vs. 2/0 AWG Wires: Key Differences and Applications

Time: 2025-05-18 14:15:28

Source: Henan Province Jianyun Cable Co., Ltd.

Overview of 2 AWG and 2/0 AWG Wires

2 AWG and 2/0 AWG wires are large-gauge conductors within the American Wire Gauge (AWG) system, designed for high-current, low-voltage applications. Often confused due to their similar sizing, these wires differ significantly in diameter, current-carrying capacity, and suitability for specific tasks. Both are typically made of copper or aluminum with insulation like polyvinyl chloride (PVC), cross-linked polyethylene (XLPE), or ethylene propylene rubber (EPR), and are used in residential, commercial, and industrial settings. Understanding their distinctions is essential for safe and efficient electrical installations, building on discussions of AWG, 6 AWG, automotive wires, solar cables, and DLO vs. welding cables.

Key Differences Between 2 AWG and 2/0 AWG Wires

2 AWG and 2/0 AWG wires differ in size, current capacity, and physical properties, impacting their performance and applications:

-

Size and Diameter: 2 AWG has a conductor diameter of approximately 0.258 inches (6.54 mm), while 2/0 AWG, also known as “two-ought,” is larger at 0.365 inches (9.27 mm). This makes 2/0 AWG about 41% larger in cross-sectional area (133,000 circular mils vs. 66,360 circular mils for 2 AWG).

-

Current-Carrying Capacity: At 90°C for copper conductors, 2 AWG can handle approximately 115A, while 2/0 AWG supports up to 175A. Aluminum conductors have lower ampacities, around 90A for 2 AWG and 135A for 2/0 AWG, due to higher resistivity.

-

Weight and Flexibility: 2/0 AWG is heavier (e.g., 0.53 lbs/ft for copper vs. 0.36 lbs/ft for 2 AWG) and less flexible due to its larger diameter and thicker insulation, making 2 AWG easier to handle in tight spaces.

-

Voltage Drop: For long runs (e.g., 100 ft), 2/0 AWG experiences less voltage drop (e.g., 2.5% vs. 3.8% for 2 AWG at 100A, copper), making it better for extended distances.

-

Cost: 2/0 AWG is more expensive due to its larger conductor size and material requirements, impacting project budgets compared to 2 AWG.

These differences determine their suitability for specific electrical loads and installation conditions.

Advantages of 2 AWG and 2/0 AWG Wires

Both wire sizes offer distinct benefits tailored to their applications:

-

2 AWG Advantages:

-

Compact Size: Smaller diameter and lighter weight make it easier to install in conduits or tight spaces, similar to automotive or household cables.

-

Cost-Effective: Lower material costs make it suitable for applications with moderate current demands, akin to 6 AWG wires.

-

Flexibility: More flexible than 2/0 AWG, ideal for dynamic or confined installations, like welding cables.

-

Sufficient Capacity: Handles up to 115A (copper), meeting needs for many residential and commercial circuits.

-

2/0 AWG Advantages:

-

Higher Current Capacity: Supports up to 175A (copper), ideal for heavy-duty loads, similar to DLO or medium-voltage cables.

-

Reduced Voltage Drop: Larger cross-section minimizes power loss over long runs, akin to solar or MV cables.

-

Durability: Thicker conductors and insulation withstand higher electrical and mechanical stress, like trailing cables.

-

Versatility: Suitable for high-power applications, including industrial and renewable energy systems.

These advantages align with their roles in balancing cost, capacity, and installation ease.

Applications of 2 AWG and 2/0 AWG Wires

2 AWG and 2/0 AWG wires serve distinct yet overlapping applications, similar to 6 AWG, solar cables, and DLO cables:

-

2 AWG Applications:

-

Residential Wiring: Powers subpanels, large appliances, or HVAC systems, handling up to 115A, like household cables.

-

Automotive: Used in high-current battery connections or audio systems, similar to automotive wires.

-

Commercial: Supports lighting, motors, or small distribution panels in offices and retail spaces.

-

Welding: Suitable for welding equipment with moderate current demands, akin to welding cables.

-

2/0 AWG Applications:

-

Industrial Power: Powers heavy machinery, pumps, or large motors in manufacturing or mining, similar to DLO cables.

-

Service Entrances: Used in main service panels or feeders for large buildings, handling up to 175A.

-

Renewable Energy: Connects inverters to grids in solar or wind systems, minimizing voltage drop, like solar cables.

-

Marine and Mining: Supports high-current equipment in harsh environments, akin to submarine cables.

2 AWG is ideal for moderate loads and confined spaces, while 2/0 AWG excels in high-power, long-distance applications.

Comparison of 2 AWG and 2/0 AWG Wires

The table below compares 2 AWG and 2/0 AWG wires, highlighting their properties:

|

Feature

|

2 AWG

|

2/0 AWG

|

|

Conductor Diameter

|

0.258 in (6.54 mm)

|

0.365 in (9.27 mm)

|

|

Cross-Sectional Area

|

66,360 circular mils

|

133,000 circular mils

|

|

Ampacity (Copper, 90°C)

|

115A

|

175A

|

|

Ampacity (Aluminum, 90°C)

|

90A

|

135A

|

|

Weight (Copper)

|

0.36 lbs/ft

|

0.53 lbs/ft

|

|

Flexibility

|

More flexible

|

Less flexible

|

|

Voltage Drop (100 ft, 100A, Copper)

|

3.8%

|

2.5%

|

|

Typical Applications

|

Residential, automotive, welding

|

Industrial, service entrances, solar

|

Tips for Selecting Between 2 AWG and 2/0 AWG Wires

Choosing between 2 AWG and 2/0 AWG wires ensures performance and safety:

-

Assess Current Requirements: Use 2 AWG for loads up to 115A (copper), like subpanels or appliances; select 2/0 AWG for higher loads up to 175A, such as industrial motors or service entrances, as discussed in AWG articles.

-

Consider Run Length: Choose 2/0 AWG for runs over 50 ft to minimize voltage drop below 3%, akin to solar or MV cables; use 2 AWG for shorter runs.

-

Evaluate Space Constraints: Opt for 2 AWG in tight spaces or conduits due to its smaller size and flexibility, similar to automotive or welding cables.

-

Balance Cost and Capacity: Select 2 AWG for cost-sensitive projects with moderate loads; use 2/0 AWG for high-power applications where capacity is critical, like DLO cables.

-

Choose Conductor Material: Prefer copper (59.6 MS/m conductivity) for high efficiency; use aluminum (37.2 MS/m) for cost savings in long runs, as in grounding discussions.

-

Consult Professionals: Engage electricians to verify sizing and installation, ensuring reliability, as with household or solar cables.

These steps align with selecting reliable wires like TR-XLPE, LSOH, or 6 AWG.

Conclusion

2 AWG and 2/0 AWG wires, while both large-gauge conductors, serve distinct roles due to differences in size, current capacity, and physical properties. 2 AWG, with a smaller diameter and 115A capacity, is ideal for residential wiring, automotive applications, and welding, offering flexibility and cost-effectiveness. 2/0 AWG, with a larger cross-section and 175A capacity, excels in industrial power, service entrances, and renewable energy systems, minimizing voltage drop over long runs. By evaluating load, distance, and installation requirements, users can select the appropriate wire, ensuring safety and efficiency. Professional consultation enhances reliability, building on discussions of AWG, automotive wires, solar cables, cable jackets, and DLO vs. welding cables.