Is XHHW the Same as XLPE? Clarifying the Relationship

Time: 2025-05-18 14:51:50

Source: Henan Province Jianyun Cable Co., Ltd.

Overview of XHHW and XLPE

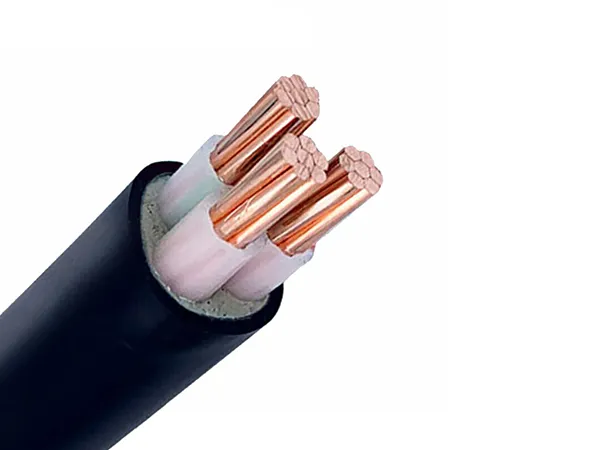

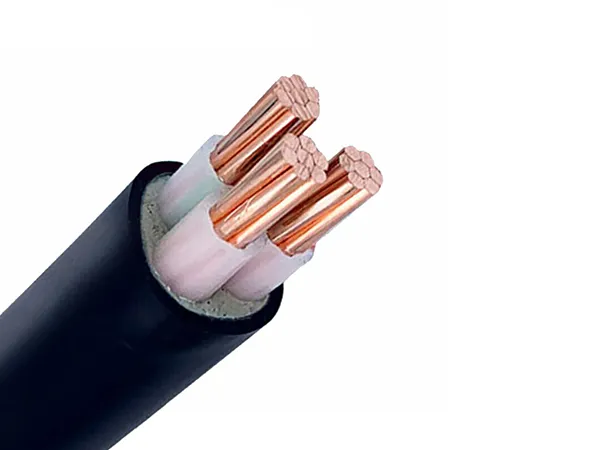

XHHW cables and XLPE (cross-linked polyethylene) are often confused due to their close association, but they are not identical. XHHW, standing for Cross-linked High Heat-resistant Water-resistant, is a type of electrical cable with specific performance characteristics, primarily using XLPE as its insulation material. XLPE is a thermoset polymer formed through a cross-linking process that enhances its thermal and mechanical properties. While XHHW cables rely on XLPE insulation, XLPE is also used in other cable types, such as building wires or photovoltaic cables. This distinction is critical for understanding their roles, as discussed in prior articles on cable jackets, PUR vs. PVC, PVC cables, and DLO vs. welding cables.

Key Differences Between XHHW and XLPE

The relationship between XHHW and XLPE is that XHHW is a cable type defined by its insulation and performance, while XLPE is the insulation material used in XHHW and other cables. Key distinctions include:

-

Scope: XHHW is a specific cable for conductors, typically copper or aluminum, insulated with XLPE, rated for low voltage, and designed for high heat and water resistance. XLPE is a material used in various cables, including high-voltage or low-smoke configurations, not limited to XHHW.

-

Application Specificity: XHHW cables are tailored for commercial and industrial wiring, often in conduits or raceways. XLPE insulation appears in diverse applications, like photovoltaic or medium-voltage cables, with different ratings and constructions.

-

Performance Variants: Enhanced XHHW cables offer superior moisture and heat resistance, still using XLPE insulation. XLPE in other cables may vary in formulation, affecting properties like smoke production or voltage ratings.

Thus, while all XHHW cables use XLPE insulation, not all XLPE-insulated cables are XHHW, highlighting their distinct roles.

Properties of XHHW Cables with XLPE Insulation

XHHW cables, leveraging XLPE insulation, exhibit properties that make them suitable for demanding environments:

-

Temperature Resistance: Rated for 90°C in dry conditions and 75°C in wet conditions, with short-term tolerance up to 250°C, XLPE’s cross-linked structure prevents softening, unlike PVC.

-

Voltage Rating: Rated for low voltage, typically up to 600V, suitable for power distribution and branch circuits.

-

Moisture Resistance: XLPE insulation resists water absorption, ensuring reliability in damp or wet locations.

-

Chemical Resistance: Resistant to oils, acids, and alkalis, XHHW cables withstand moderate chemical exposure, outperforming PVC cables.

-

Mechanical Strength: XLPE’s cross-linked structure provides high tensile and compressive strength, resisting abrasion and impact during installation.

-

Aging Resistance: XLPE insulation slows degradation, extending cable lifespan compared to thermoplastic materials like PVC.

These properties align XHHW cables with applications requiring durability, as discussed in articles on cross-linked insulation and photovoltaic cables.

Advantages of XHHW Cables

XHHW cables, with XLPE insulation, offer several benefits:

-

High Heat Resistance: Operate reliably at 90°C, surpassing PVC cables, ideal for high-temperature environments, similar to cross-linked insulation cables.

-

Moisture Resistance: Perform well in wet locations, reducing corrosion risks, akin to underground cables.

-

Durability: XLPE’s mechanical strength resists wear, extending lifespan in harsh settings, like heavy-duty cables.

-

Chemical Stability: Resist degradation from oils and chemicals, outperforming PVC, as noted in material comparison discussions.

-

Compact Design: XLPE’s high dielectric strength allows thinner insulation than PVC for the same voltage, reducing cable diameter.

-

Versatility: Suitable for conduits, raceways, or direct burial with appropriate configurations, similar to multi-core cables.

These advantages make XHHW cables a robust choice for demanding installations.

Applications of XHHW Cables

XHHW cables are used in various sectors, similar to applications of conductor sizing, photovoltaic cables, and heavy-duty cables:

-

Commercial Buildings: Powers lighting, HVAC, and distribution panels in offices and retail spaces, leveraging heat and moisture resistance.

-

Industrial Facilities: Supports machinery, motors, and control systems in factories, where chemical and abrasion resistance is critical, akin to heavy-duty cables.

-

Power Distribution: Used in branch circuits and feeders within conduits or raceways, similar to general-purpose wiring cables.

-

Outdoor Installations: Enhanced XHHW cables suit wet or corrosive environments, like photovoltaic or underground cables.

-

Renewable Energy: Connects inverters to grids in solar systems, benefiting from XLPE’s durability, as discussed in photovoltaic cable articles.

These applications highlight XHHW’s role in reliable, high-performance wiring.

Comparison of XHHW and Other XLPE Cables

The table below compares XHHW cables with other XLPE-insulated cables, highlighting their properties:

|

Feature

|

XHHW Cable

|

Building Wire Cable

|

Photovoltaic Cable

|

|

Insulation Material

|

XLPE

|

XLPE

|

XLPE

|

|

Voltage Rating

|

600V

|

600V

|

1000V–2000V

|

|

Temperature (Dry/Wet)

|

90°C/75°C

|

90°C/90°C

|

90°C/90°C

|

|

Moisture Resistance

|

High

|

Moderate

|

High

|

|

Chemical Resistance

|

Moderate

|

Moderate

|

High

|

|

Typical Applications

|

Commercial, industrial

|

Building interiors

|

Solar PV systems

|

Tips for Selecting XHHW Cables

Choosing XHHW cables ensures performance and safety in appropriate applications:

-

Assess Environmental Conditions: Use XHHW for high-temperature, up to 90°C, or wet environments; for enhanced moisture resistance, select advanced XHHW variants, similar to underground cables.

-

Evaluate Load Requirements: Select conductor sizes, such as 2 AWG for 115A with copper, using ampacity guidelines, as discussed in conductor sizing articles.

-

Consider Installation Type: Opt for XHHW in conduits or raceways for commercial or industrial wiring; ensure proper configurations for direct burial, akin to photovoltaic cables.

-

Compare with Alternatives: Choose XHHW over PVC cables for better heat and chemical resistance; for low-smoke needs, consider alternative insulation, as noted in low-smoke cable discussions.

-

Check Mechanical Stress: XLPE’s durability suits installations with abrasion or impact risks, similar to heavy-duty or trailing cables.

-

Consult Professionals: Engage electricians to verify sizing and installation, ensuring reliability, as with household or photovoltaic cables.

These steps align with selecting reliable cables like cross-linked insulation, automotive, or photovoltaic cables.

Conclusion

XHHW cables are a specific type of cable using XLPE insulation, distinguished by their low-voltage rating, high heat resistance, up to 90°C in dry conditions and 75°C in wet, and suitability for commercial and industrial applications. XLPE, as a versatile insulation material, appears in various cables, including building wires and photovoltaic cables, with different ratings and purposes. XHHW’s advantages, such as durability, moisture resistance, and chemical stability, make it ideal for demanding environments, while its limitations compared to low-smoke or high-voltage XLPE cables require careful selection. By evaluating environmental, load, and installation needs, users can leverage XHHW cables for reliable performance, building on discussions of conductor sizing, cable jackets, PVC cables, and heavy-duty cables. Professional consultation enhances the effectiveness of XHHW cable installations, supporting robust electrical systems across various sectors.