Buyer’s Guide: What You Need to Know Before Purchasing Industrial Cables

Time: 2025-05-27 15:50:58

Source: Henan Province Jianyun Cable Co., Ltd.

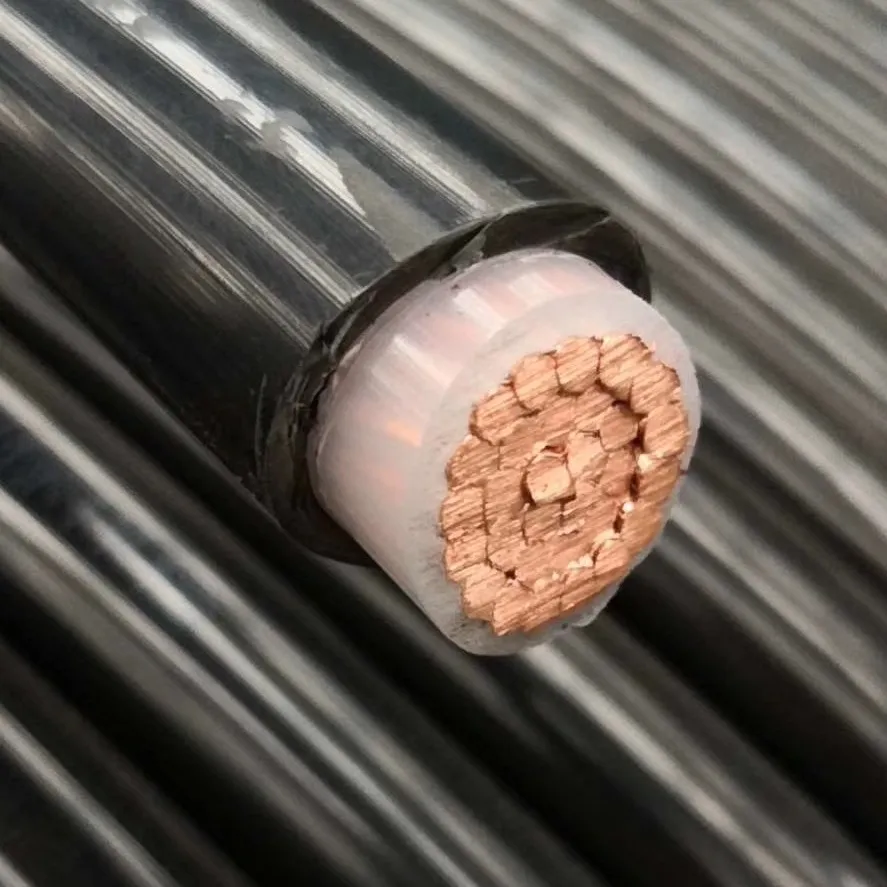

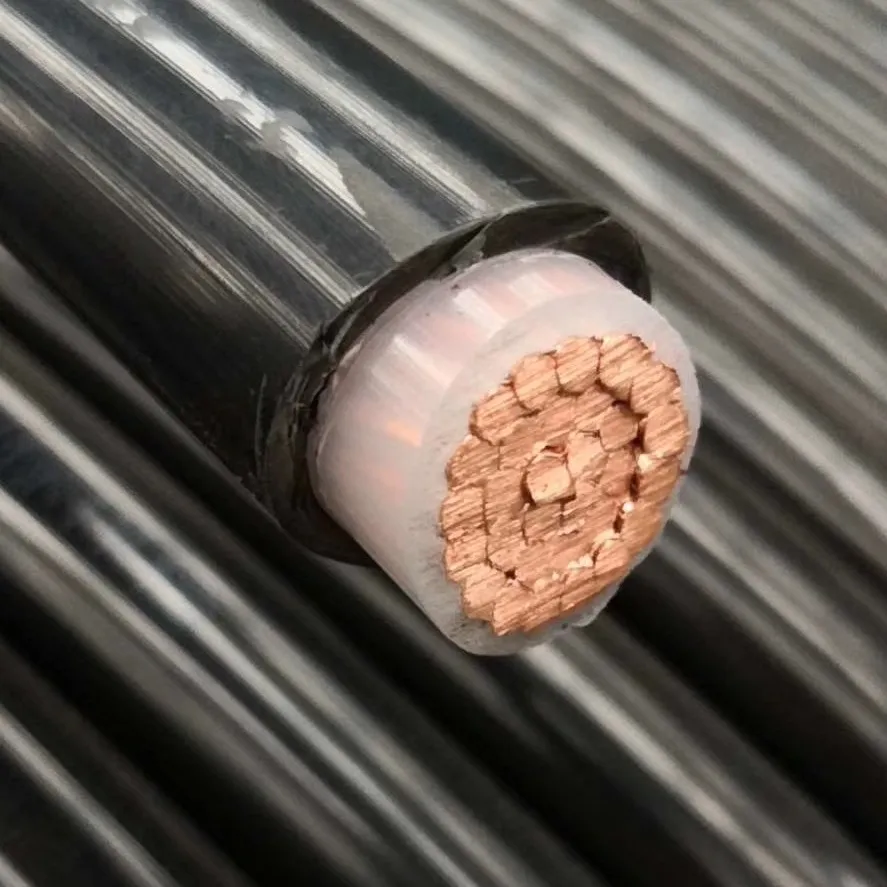

Overview of Industrial Cables

Industrial cables are specialized electrical cables designed to transmit power, control signals, or data in demanding environments such as manufacturing plants, construction sites, and utility networks. Engineered for durability, safety, and performance, these cables withstand harsh conditions including extreme temperatures, mechanical stress, and chemical exposure. Selecting the right industrial cable is critical for ensuring operational efficiency and safety. Jianyun Cable Co., based in Luoyang, China, is a leading provider of industrial cables, offering robust solutions for diverse applications, as discussed in prior articles on conductor cables, armored cables, and fire-resistant cables.

Types of Industrial Cables

Industrial cables are categorized based on their function, construction, and application:

-

Power Cables: Transmit electricity at low (up to 1kV), medium (1–35kV), or high voltage (>35kV), using copper or aluminum conductors with insulation like cross-linked polyethylene (XLPE), similar to RW90 or TR-XLPE cables.

-

Control Cables: Multi-core cables (300/500V) for automation and signal transmission, often with shielding or armor, comparable to SY cables.

-

Instrumentation Cables: Low-voltage cables with enhanced shielding for precise data or signal transmission in industrial control systems.

-

Armored Cables: Power or control cables with steel or aluminum armor for mechanical protection, ideal for rugged environments, as discussed in armored cable articles.

-

Fire-Resistant Cables: Cables with mica tape or low-smoke zero-halogen (LSZH) sheathing, designed to maintain functionality during fires, as explored in fire-resistant cable discussions.

-

Specialty Cables: Include solar cables for photovoltaic systems or cables for extreme temperatures, tailored for specific industrial needs, akin to custom cables.

Each type addresses unique requirements in industrial settings, ensuring reliability and safety.

Key Considerations for Purchasing

Before purchasing industrial cables, several factors must be evaluated to ensure suitability:

-

Voltage and Load Requirements: Determine the voltage rating and current capacity (e.g., 2 AWG for 115A, copper) to match the application, as discussed in AWG articles.

-

Environmental Conditions: Assess exposure to moisture, UV, chemicals, or extreme temperatures, selecting cables with appropriate insulation (e.g., XLPE) or sheathing (e.g., LSZH), similar to RWU90 or solar cables.

-

Mechanical Durability: Choose armored cables for high-impact areas or flexible cables for dynamic applications, as in armored or control cable discussions.

-

Fire Safety: Opt for fire-resistant or LSZH cables in high-risk environments to ensure safety, as detailed in fire-resistant cable articles.

-

Installation Constraints: Consider cable flexibility, bending radius, and space limitations, particularly for multi-core or instrumentation cables.

-

Cost Efficiency: Balance initial costs with longevity, opting for aluminum conductors for affordability or copper for high conductivity, as explored in conductor cable articles.

-

Regulatory Compliance: Ensure cables meet safety and performance expectations for the target market, as discussed in exported power cable articles, without specifying standards per user instructions.

These considerations guide the selection of cables that meet operational and safety needs.

Jianyun Cable’s Industrial Cable Solutions

Jianyun Cable Co. offers a comprehensive range of industrial cables tailored to demanding applications:

-

Power Cables: Low, medium, and high voltage cables with XLPE or PVC insulation, suitable for industrial power distribution, akin to RW90 or TR-XLPE.

-

Control Cables: Multi-core cables with shielding or steel wire armor, designed for automation systems, comparable to SY cables.

-

Instrumentation Cables: Shielded cables for precise signal transmission in control systems, ensuring reliability in industrial environments.

-

Armored Cables: Steel or aluminum-armored cables for rugged installations, providing mechanical protection, as discussed in armored cable articles.

-

Fire-Resistant Cables: Cables with mica tape or LSZH sheathing, ideal for high-safety industrial settings, as explored in fire-resistant cable discussions.

-

Custom Industrial Cables: Tailored solutions with specific conductor sizes, insulation, or armor, addressing unique project needs, as in custom cable articles.

Jianyun’s advanced manufacturing ensures high-quality cables for global industrial projects.

Applications of Industrial Cables

Industrial cables support a wide range of applications in demanding environments:

-

Manufacturing Plants: Power cables supply machinery, while control cables manage automation, similar to TR-XLPE or SY cable uses.

-

Construction Sites: Armored cables provide durable power distribution, withstanding physical stress, as discussed in armored cable articles.

-

Utility Networks: Medium and high voltage cables support power distribution, while fire-resistant cables ensure safety, akin to RWU90 or fire-resistant cables.

-

Renewable Energy: Solar cables connect photovoltaic systems, leveraging UV-resistant insulation, as explored in solar cable discussions.

-

Chemical and Oil Industries: Fire-resistant and LSZH cables ensure safety in hazardous areas, as detailed in fire-resistant cable articles.

-

Data and Control Systems: Instrumentation cables transmit precise signals in industrial automation, ensuring operational efficiency.

These applications highlight the critical role of industrial cables in robust infrastructure.

Summary of Industrial Cable Types

The table below summarizes key industrial cable types and their purchasing considerations:

|

Cable Type

|

Key Features

|

Purchasing Considerations

|

|

Power Cable

|

XLPE/PVC insulation, various voltages

|

Voltage, load, environmental resistance

|

|

Control Cable

|

Multi-core, shielding/armor

|

Signal integrity, flexibility

|

|

Instrumentation Cable

|

Enhanced shielding, low voltage

|

Data accuracy, interference protection

|

|

Armored Cable

|

Steel/aluminum armor

|

Mechanical durability, rugged environments

|

|

Fire-Resistant Cable

|

Mica tape, LSZH sheathing

|

Fire safety, low smoke emission

|

|

Specialty Cable

|

UV-resistant, extreme conditions

|

Specific environmental or application needs

|

Practical Purchasing Tips

To make informed purchasing decisions, consider the following practical tips:

-

Define Project Specifications: Clearly outline voltage, load, and environmental requirements to select the appropriate cable type, as in RW90 or TR-XLPE discussions.

-

Evaluate Supplier Expertise: Choose manufacturers like Jianyun with advanced facilities and a proven track record, as noted in their Elektro 2025 participation.

-

Request Customization: Opt for tailored cables to meet unique project needs, such as specific conductor sizes or insulation, as discussed in custom cable articles.

-

Assess Long-Term Costs: Prioritize durable cables to minimize maintenance, balancing initial costs with longevity, as with XLPE or armored cables.

-

Verify Compatibility: Ensure cables are compatible with existing systems or equipment, particularly for instrumentation or control cables.

-

Consult Professionals: Engage engineers or electricians to validate cable selection and installation, ensuring safety and efficiency, as with T90 or fire-resistant cables.

-

Plan for Scalability: Select cables that accommodate future expansions or upgrades, particularly for industrial or utility applications.

These tips ensure the selection of reliable and cost-effective industrial cables.

Conclusion

Purchasing industrial cables requires careful consideration of voltage requirements, environmental conditions, mechanical durability, and safety features to ensure optimal performance and reliability. Available in power, control, instrumentation, armored, fire-resistant, and specialty variants, industrial cables support critical applications in manufacturing, construction, and utilities. Jianyun Cable Co., based in Luoyang, China, offers a comprehensive portfolio of industrial cables, leveraging advanced manufacturing to deliver tailored solutions for global projects. By defining project specifications, evaluating suppliers, and consulting professionals, buyers can select the ideal industrial cable, building on discussions of AWG, XHHW vs. XLPE, and fire-resistant cables. Strategic purchasing decisions enhance the safety and efficiency of industrial electrical systems, supporting robust and sustainable infrastructure.