Time: 2025-05-27 16:08:16 Source: Henan Province Jianyun Cable Co., Ltd.

Power and control cables are essential components in electrical systems, enabling the transmission of electricity and signals in industrial, commercial, and residential applications. Power cables deliver electrical energy across various voltage levels, while control cables transmit low-voltage signals for automation and equipment operation. Understanding their differences, materials, and applications is crucial for buyers to make informed purchasing decisions. Jianyun Cable Co., based in Luoyang, China, offers a wide range of power and control cables, addressing diverse project needs, as discussed in prior articles on conductor cables, armored cables, and industrial cables.

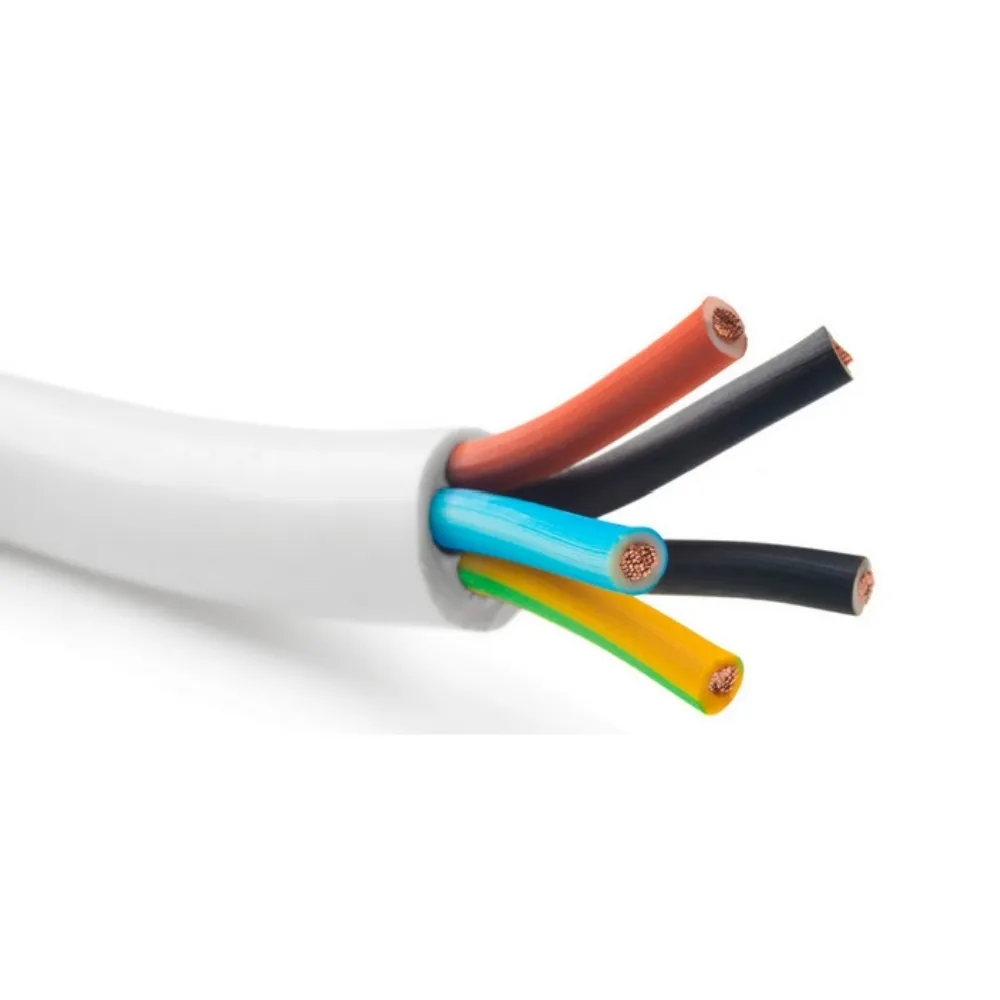

Power cables are designed to transmit electrical energy, typically at low (up to 1kV), medium (1–35kV), or high voltage (>35kV), using robust conductors like copper or aluminum with insulation such as cross-linked polyethylene (XLPE), similar to RW90 or TR-XLPE cables. Control cables, rated for low voltages (300/500V), transmit signals for automation, featuring multiple cores and shielding to prevent interference, akin to SY cables. Power cables prioritize high current capacity, while control cables focus on signal accuracy and flexibility, as explored in conductor cable discussions.

Power cables typically use copper conductors for high conductivity or aluminum for cost efficiency, with XLPE or polyvinyl chloride (PVC) insulation for electrical and thermal resistance, as detailed in XLPE insulation articles. Control cables employ copper conductors for precise signal transmission, with PVC or low-smoke zero-halogen (LSZH) insulation and optional shielding or armor. Sheathing materials, such as PVC or LSZH, provide environmental protection, while mica tape enhances fire resistance in some cables, as discussed in fire-resistant cable articles.

Select cables based on the system’s voltage requirements: low voltage cables (up to 1kV) for residential or commercial wiring (e.g., RW90, T90), medium voltage (1–35kV) for industrial distribution (e.g., TR-XLPE, RWU90), and high voltage (>35kV) for long-distance transmission. Ensure the insulation, such as XLPE, supports the voltage level to prevent breakdown, and verify conductor size for current capacity, as explored in AWG and exported power cable discussions. Consulting with manufacturers like Jianyun ensures compatibility.

Consider exposure to moisture, UV radiation, chemicals, or extreme temperatures. For wet or underground environments, choose cables with moisture-resistant insulation like XLPE, similar to RWU90. For outdoor use, select UV-resistant sheathing, as in solar cables. In chemical plants, opt for cables resistant to oils and acids. For high-temperature areas, ensure thermal stability with XLPE or mica tape, as discussed in XLPE insulation and fire-resistant cable articles. Armored cables offer additional protection in harsh conditions.

Fire-resistant cables are essential in high-risk environments like commercial buildings, industrial facilities, or public infrastructure, where maintaining circuit integrity during fires is critical. These cables, featuring mica tape or LSZH sheathing, support emergency systems like alarms and lighting, as detailed in fire-resistant cable articles. For low-risk settings, standard cables like RW90 may suffice, but LSZH cables are recommended in confined spaces to reduce toxic smoke, ensuring occupant safety.

Armored cables, equipped with steel or aluminum armor, provide superior mechanical protection against impact, crushing, or rodent damage, making them ideal for industrial, underground, or exposed installations. They enhance durability in rugged environments, as discussed in armored cable articles, and are available as power or control cables. While more expensive than non-armored cables like T90, their longevity and safety benefits, similar to RWU90 applications, justify the investment in harsh conditions.

Cable size depends on current capacity, voltage drop, and installation conditions. Use conductor sizes like 2 AWG (115A, copper) for high loads, as explored in AWG articles. Calculate ampacity based on load requirements, ensuring the conductor and insulation handle the current without overheating. Consider cable length to minimize voltage drop, especially in long runs. Consult load charts or professionals to match sizes to applications, as with TR-XLPE or control cables, ensuring efficiency and safety.

Yes, cables can be customized to meet specific voltage, environmental, or installation needs. Manufacturers like Jianyun offer tailored solutions, adjusting conductor sizes, insulation types (e.g., XLPE, LSZH), shielding, or armor, as discussed in custom cable articles. Customization is ideal for unique projects, such as automation systems requiring multi-core control cables or solar installations needing UV-resistant power cables. Collaboration with suppliers ensures cables align with project specifications, enhancing performance and reliability.

The lifespan of power and control cables typically ranges from 20 to 50 years, depending on materials, environmental conditions, and usage. XLPE-insulated cables, like RW90 or TR-XLPE, offer durability up to 40–50 years due to thermal and environmental resistance, as discussed in XLPE insulation articles. Armored or LSZH cables extend lifespan in harsh settings. Proper installation and maintenance, avoiding overloading or physical damage, maximize longevity, as seen in industrial cable applications.

Jianyun Cable Co., based in Luoyang, China, is a trusted manufacturer offering high-quality power and control cables. Their portfolio includes low, medium, and high voltage power cables, control cables, armored, and fire-resistant variants, tailored to diverse needs, as explored in prior articles. Jianyun’s advanced manufacturing, customization capabilities, and customer-centric approach ensure reliable solutions for global projects, as noted in their Elektro 2025 participation. Their focus on durability and performance makes them a preferred choice.

The table below summarizes key buyer considerations for power and control cables:

| Question | Key Considerations | Relevant Cable Types |

|---|---|---|

| Difference between cable types | Power for energy, control for signals | RW90, TR-XLPE, SY |

| Materials used | Copper/aluminum, XLPE/PVC, LSZH | RW90, fire-resistant, control |

| Voltage needs | Low/medium/high voltage compatibility | RW90, TR-XLPE, high voltage |

| Environmental factors | Moisture, UV, temperature resistance | RWU90, solar, armored |

| Fire resistance | Safety in high-risk areas | Fire-resistant, LSZH |

| Armored benefits | Mechanical protection, durability | Armored power/control |

| Cable sizing | Ampacity, voltage drop, load | 2 AWG, TR-XLPE, control |

| Customization | Tailored conductors, insulation | Custom power/control |

| Lifespan | 20–50 years, material-dependent | XLPE, armored, LSZH |

| Supplier choice | Quality, customization, reliability | Jianyun’s portfolio |

Power and control cables are vital for efficient and safe electrical systems, with buyers frequently seeking clarity on their differences, materials, and applications. Addressing common questions—such as voltage compatibility, environmental resistance, and customization—helps buyers make informed decisions. Jianyun Cable Co., based in Luoyang, China, provides a comprehensive range of power and control cables, offering durable, tailored solutions for industrial, commercial, and infrastructure projects. By evaluating project needs, environmental factors, and supplier expertise, buyers can select the ideal cables, building on discussions of AWG, XHHW vs. XLPE, and fire-resistant cables. Professional consultation ensures optimal performance, reinforcing the critical role of these cables in modern electrical infrastructure.