Time: 2025-06-03 15:01:31 Source: Henan Province Jianyun Cable Co., Ltd.

Industrial control cables form the backbone of modern automated systems, ensuring reliable signal transmission between sensors, actuators, and control units to maintain seamless operations. By providing robust, shielded pathways for data and power, control cables minimize electromagnetic interference and reduce the risk of signal degradation, which is essential for precise machine coordination. In hazardous environments such as oil, gas, and chemical plants, specially designed control cables with flame-retardant and chemical-resistant jackets help prevent electrical faults from escalating into catastrophic incidents. Moreover, continuous condition monitoring of these cables enables predictive maintenance, detecting insulation breakdowns or partial discharges before they cause unplanned downtime or safety hazards. As automation technology evolves toward Industry 4.0, smart control cables with embedded sensors provide real-time diagnostics, thereby enhancing both operational efficiency and workplace safety.

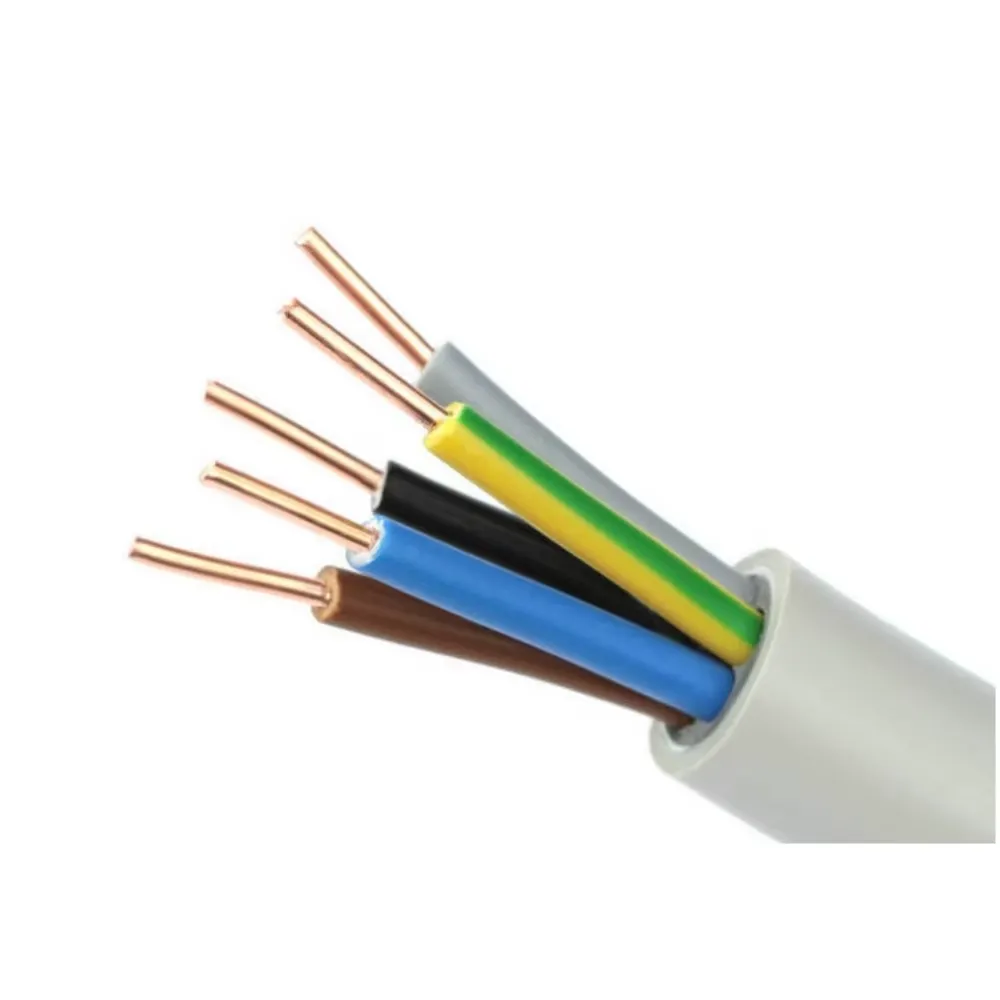

Industrial control cables are specialized electrical cables designed to transmit signals, power, and data in automated systems that manage machinery, robotics, and process controls. They differ from standard power cables by incorporating multiple insulated conductors, advanced shielding, and ruggedized outer jackets to withstand mechanical, thermal, and chemical stresses. By facilitating communication between programmable logic controllers (PLCs), human-machine interfaces (HMIs), sensors, and actuators, control cables enable centralized monitoring and real-time decision-making in manufacturing and processing facilities.

In complex automation networks, multiple signals operate simultaneously, creating electromagnetic noise that can corrupt data transmission. Control cables employ shielding—such as braided copper or aluminum foil layers—to isolate individual conductors and prevent crosstalk, ensuring that sensor readings and control commands remain accurate. This level of signal integrity is especially critical for high-speed data communication protocols and precise motion control applications.

Multicore control cables combine several signal and power conductors within a single sheath, reducing cable clutter and simplifying installation within cable trays and conduit systems. Their modular nature allows engineers to add or remove conductors as control requirements evolve, supporting system scalability without extensive rewiring. Additionally, flexible constructions with finely stranded conductors enable tight bend radii and ease routing in dynamic robotic cells or moving parts.

In environments where flammable gases or combustible materials exist, control cables with flame-retardant sheaths inhibit flame spread and limit smoke generation during a fire. Low Smoke Zero Halogen (LSZH) jackets further reduce toxic gas emissions, improving evacuation conditions and lowering the risk of inhalation injuries. Compliance with standards such as IEC 60332 and UL VW-1 ensures that these cables meet stringent safety criteria for industrial use.

Industrial facilities often expose cables to harsh chemicals, oils, moisture, and abrasion. Control cables constructed with cross-linked polyethylene (XLPE) or polyvinyl chloride (PVC) compounds offer superior resistance to chemical attack and physical damage. Armored variants—featuring steel wire armor (SWA) or steel tape armor (STA)—provide additional mechanical protection in areas prone to impact or rodent interference.

Ongoing condition monitoring using partial discharge testing, time-domain reflectometry (TDR), and Tan Delta measurements can detect early signs of insulation degradation or conductor faults. By identifying hotspots, moisture ingress, or partial discharges before failure, plant operators can schedule maintenance proactively, reducing unplanned downtime and preventing safety incidents. Intelligent “smart” control cables with embedded sensors relay real-time diagnostics to centralized maintenance systems, enabling data-driven decision-making and enhancing overall equipment safety.

Shielding techniques—such as individual conductor shields and overall cable braids—guard against electromagnetic interference (EMI) in noisy industrial environments. High-grade insulation materials such as XLPE and PVC maintain dielectric strength at elevated temperatures while resisting moisture and chemical exposure.

Outer jackets made from flame-retardant PVC, LSZH, or polyurethane (PUR) provide abrasion resistance, UV protection, and chemical stability. Armored designs incorporating SWA or STA protect against mechanical damage in tray-mounted, underground, or exposed installations.

Industrial environments often involve high motor-generated heat and exposure to hydraulic oils or lubricants. Control cables rated for continuous operation at temperatures up to 90 °C (XLPE) or 70 °C (PVC) ensure reliable performance under thermal stress. Oil-resistant inner sheaths prevent degradation when cables are routed near pumps, conveyors, or hydraulic systems.

Adhering to recommended minimum bend radii—typically six to ten times the cable diameter—prevents conductor deformation and signal attenuation. Securing cables with clamps or cable ties at regular intervals reduces mechanical stress and prolongs service life.

Using manufacturer-specified glands, lugs, and ferrules ensures proper electrical contact and strain relief. For aluminum conductors, applying anti-oxidation compounds and using CO/ALR-rated connectors prevents contact resistance increases over time.

Periodic visual inspections identify physical damage, insulation cracks, or moisture ingress before failures occur. Insulation resistance tests (Megger) and thermographic surveys under load reveal developing insulation faults or loose connections. Implementing a preventive maintenance program based on real-time cable diagnostics minimizes unplanned downtime and enhances workplace safety.

Industrial control cables are indispensable for reliable automation and safety across manufacturing, processing, and critical infrastructure sectors. Their specialized construction—incorporating robust insulation, shielding, and armoring—ensures accurate signal transmission while withstanding harsh environmental conditions. Through flame-retardant, low-smoke, and chemical-resistant designs, control cables mitigate fire and electrical hazards, thereby safeguarding personnel and assets. With the advent of smart cable technologies, real-time condition monitoring further elevates safety and efficiency by enabling predictive maintenance. By following best practices in selection, installation, and maintenance, plant operators can optimize automation performance and minimize safety risks over the cable’s lifecycle.