Time: 2025-06-12 14:53:12 Source: Henan Province Jianyun Cable Co., Ltd.

For outdoor industrial applications, selecting the appropriate cable is critical to ensure reliability, safety, and longevity under harsh conditions. This analysis evaluates why armored cables are the optimal choice for such environments, detailing their advantages, types, and practical considerations for selection.

Outdoor industrial environments, such as manufacturing plants, construction sites, mining operations, or utility installations, expose cables to mechanical stress, moisture, extreme temperatures, UV radiation, and potential rodent damage. Armored cables are engineered to withstand these conditions, offering robust protection and reliability.

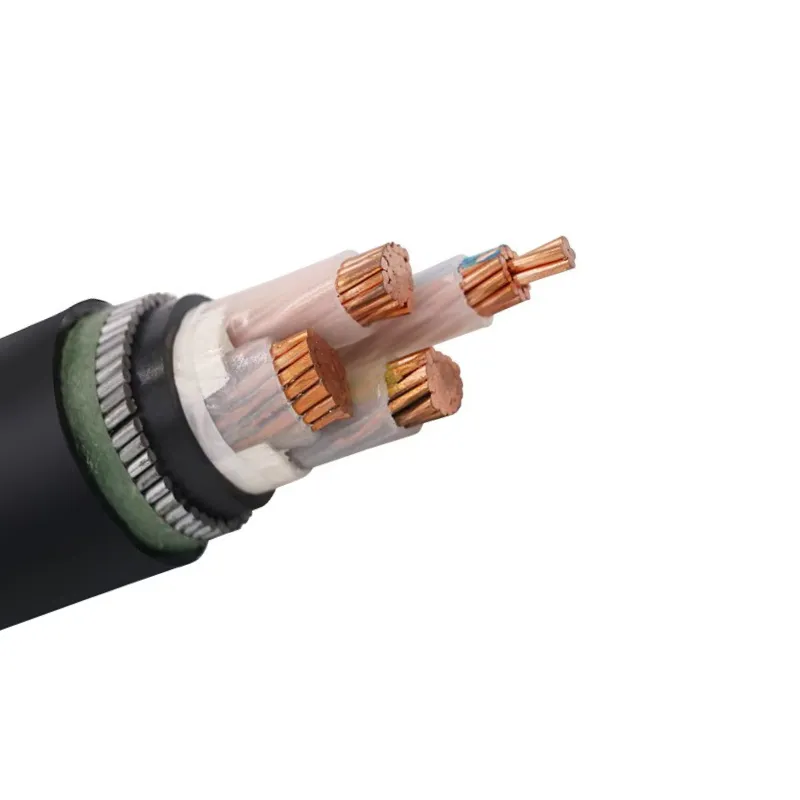

Armored cables feature a protective layer, typically steel or aluminum (e.g., steel wire or tape armoring), encasing insulated conductors. This armoring resists impacts, crushing, and abrasion, common risks in industrial settings with heavy machinery, tools, or vehicular traffic. This durability ensures operational continuity in environments where cables are susceptible to physical damage from equipment, debris, or ground movement.

Armored cables are designed to withstand environmental challenges. They include moisture-resistant features, such as flooding compounds or sealed designs, to prevent water ingress, critical for outdoor applications exposed to rain, humidity, or flooding. The metal armoring and outer jackets (e.g., PVC or XLPE) resist UV exposure and temperature fluctuations. Additionally, armored cables protect against rodent damage, extending service life in remote or rural industrial sites.

Armored cables are ideal for direct burial in underground applications, common in industrial settings for power distribution or equipment connections across large sites. Their robust construction allows installation in rocky or uneven terrain without additional conduit protection in many cases. They are versatile for aerial, underground, or surface-mounted configurations, accommodating diverse industrial layouts.

The metal armoring in armored cables can serve as a grounding path, enhancing electrical safety in high-voltage applications or environments with electromagnetic interference (e.g., RF environments). This feature reduces the need for separate grounding conductors in some designs, simplifying installation and improving safety in complex industrial electrical systems.

Armored cables support high voltages (up to 30kV) and are suitable for high-tension (HT) and low-tension (LT) applications, making them appropriate for industrial power distribution, heavy machinery, and large-scale equipment.

Several types of armored cables are suitable for outdoor industrial applications, depending on specific requirements:

Unarmored cables, such as Non-Metallic Sheathed Cable (NM) or Underground Feeder (UF) cable, are generally unsuitable for outdoor industrial environments due to:

When selecting an armored cable for outdoor industrial use, consider the following:

| Feature | Armored Cable (e.g., SWA, MC) | Unarmored Cable (e.g., NM, UF) |

|---|---|---|

| Mechanical Protection | High (resists impact, crushing) | Low (vulnerable to damage) |

| Environmental Resistance | High (moisture, UV, rodents) | Low (requires conduit) |

| Suitability for Direct Burial | Yes | No (needs protection) |

| Flexibility | Lower (larger bending radius) | Higher (easier to install) |

| Cost | Higher (approximately 15% more) | Lower |

| Industrial Use | Ideal for harsh outdoor settings | Unsuitable without protection |

For outdoor industrial use, armored cables, particularly Steel Wire Armored (SWA) or Metal-Clad (MC) cables, are the optimal choice due to their robust construction, environmental resistance, and suitability for high-stress applications. Unarmored cables lack the durability and protection required for such demanding conditions. Consulting a professional ensures the selected cable meets project requirements and complies with applicable regulations.