Time: 2025-05-07 15:07:10 Source: Henan Province Jianyun Cable Co., Ltd.

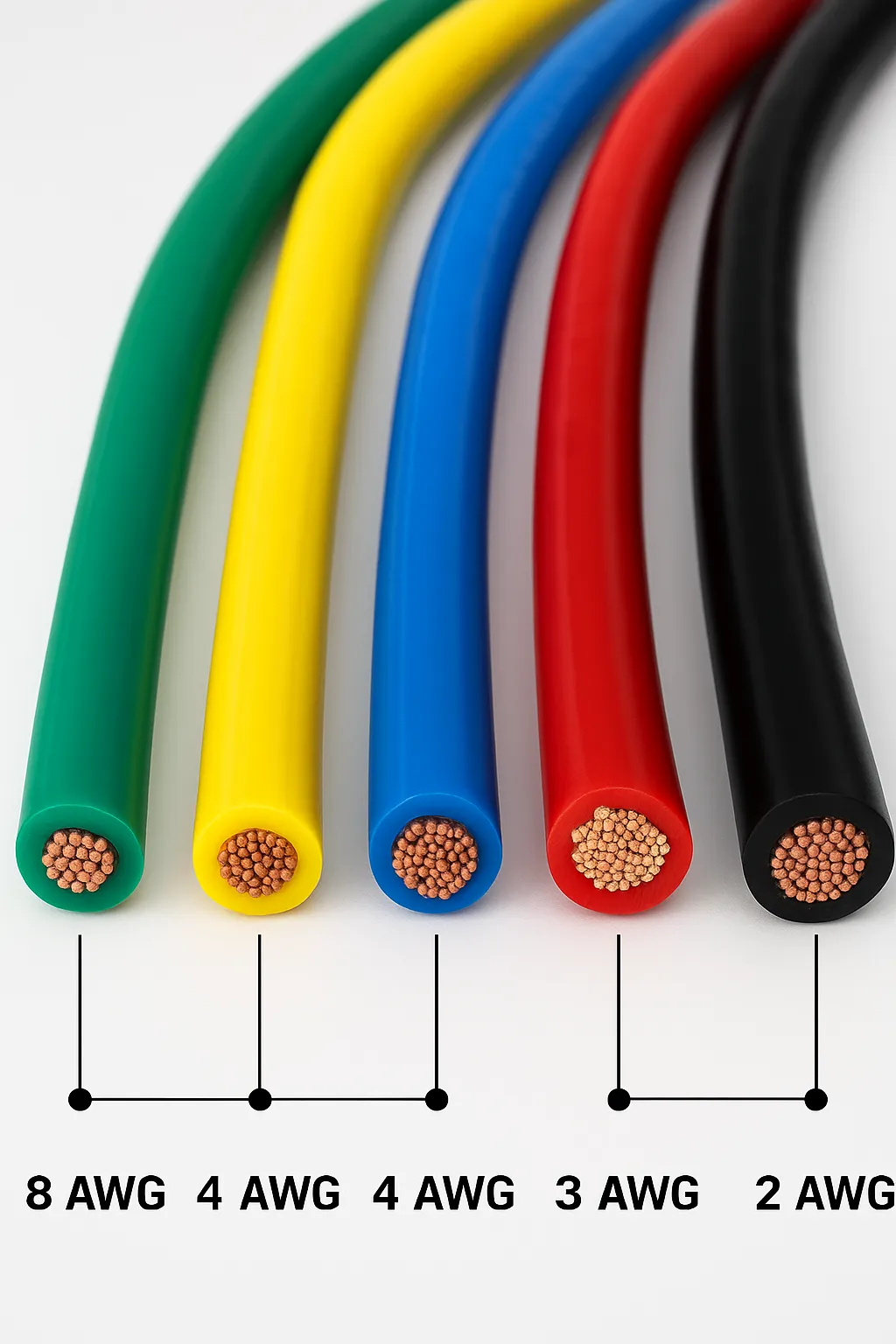

The American Wire Gauge (AWG) system is a standardized method used primarily in North America to measure the diameter of electrically conductive wires. It assigns a numerical value to each wire size, where a smaller AWG number indicates a thicker wire with a larger cross-sectional area, capable of carrying more electrical current. The AWG system is essential for electricians, engineers, and DIY enthusiasts to select the appropriate wire for specific applications, ensuring safety and efficiency.

The AWG system is logarithmic, meaning the wire diameter decreases as the gauge number increases. For every 6 AWG increments, the wire’s cross-sectional area is roughly halved, and its diameter is reduced by about 0.707. For example:

This system allows precise specification of wire sizes, with smaller gauges (e.g., 2 AWG) used for high-current applications and larger gauges (e.g., 18 AWG) for low-current needs like electronics.

Different AWG sizes are suited for specific applications based on their current-carrying capacity (ampacity). Below is a table summarizing common AWG sizes, their specifications, and typical uses:

| AWG Size | Diameter (inches) | Cross-Sectional Area (mm²) | Typical Ampacity (Copper, 75°C) | Common Applications |

|---|---|---|---|---|

| 4 AWG | 0.204 | 21.2 | 85-95 amps | Service entrance, large appliances |

| 6 AWG | 0.162 | 13.3 | 55-65 amps | Electric ranges, HVAC, subpanels |

| 10 AWG | 0.102 | 5.3 | 30-35 amps | Water heaters, small appliances |

| 12 AWG | 0.081 | 3.3 | 20-25 amps | Household lighting, outlets |

| 14 AWG | 0.064 | 2.1 | 15-20 amps | Low-power lighting, small electronics |

Note: Ampacity varies based on insulation type, ambient temperature, and installation conditions. Always refer to the National Electrical Code (NEC) for precise ratings.

The material of a wire significantly impacts its performance and application:

For example, a 6 AWG copper wire can handle ~55-65 amps, while a 6 AWG aluminum wire is limited to ~40-50 amps under similar conditions. Material choice depends on cost, weight, and conductivity needs.

Wires can be either solid or stranded, each with distinct advantages:

For instance, a 6 AWG stranded wire is often used in flexible cables, while a solid 6 AWG wire might be chosen for permanent residential circuits.

Choosing the correct AWG size is critical to prevent electrical hazards. Key safety considerations include:

The AWG system simplifies the selection of wire sizes for electrical applications, balancing current capacity, material properties, and installation needs. By understanding AWG specifications, common sizes, and safety practices, you can make informed decisions for safe and efficient wiring projects. Whether you’re wiring a home, powering heavy equipment, or tackling a DIY project, the AWG system is your guide to reliable electrical performance.