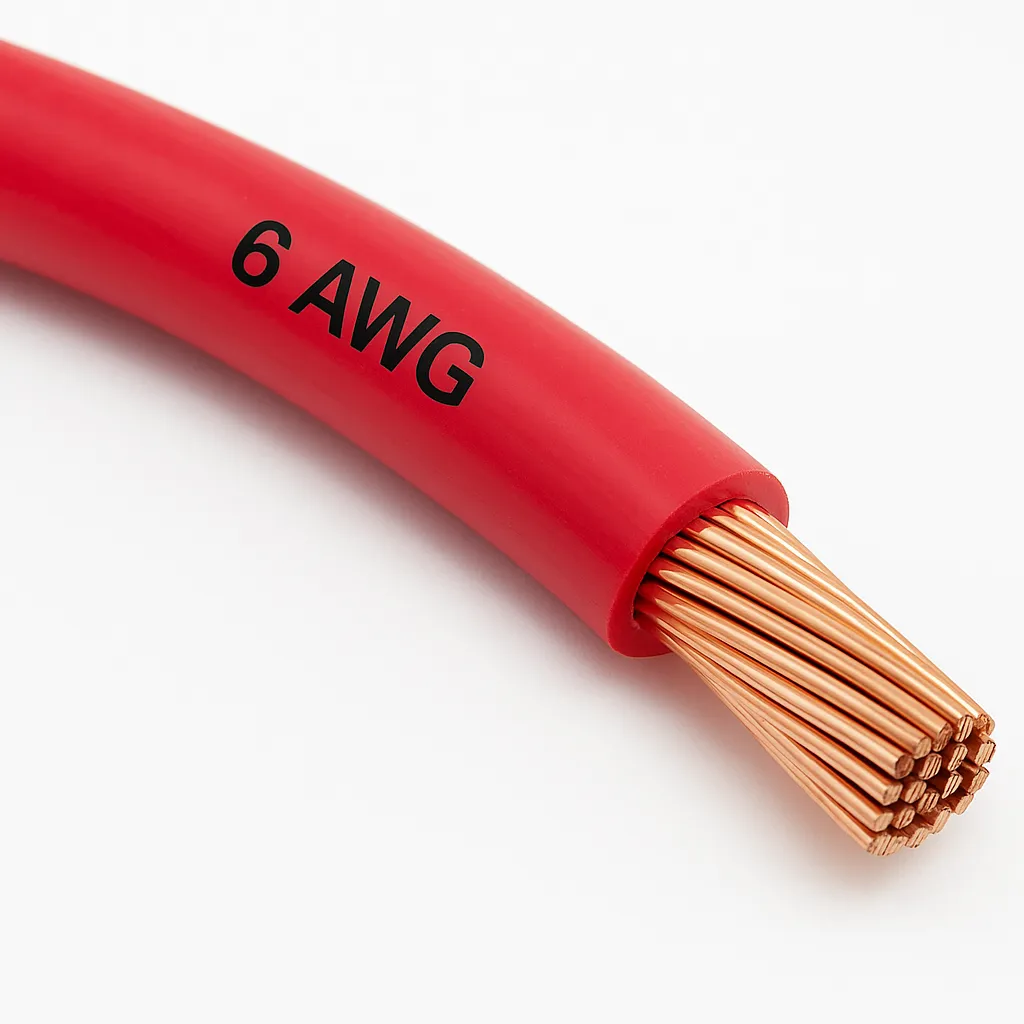

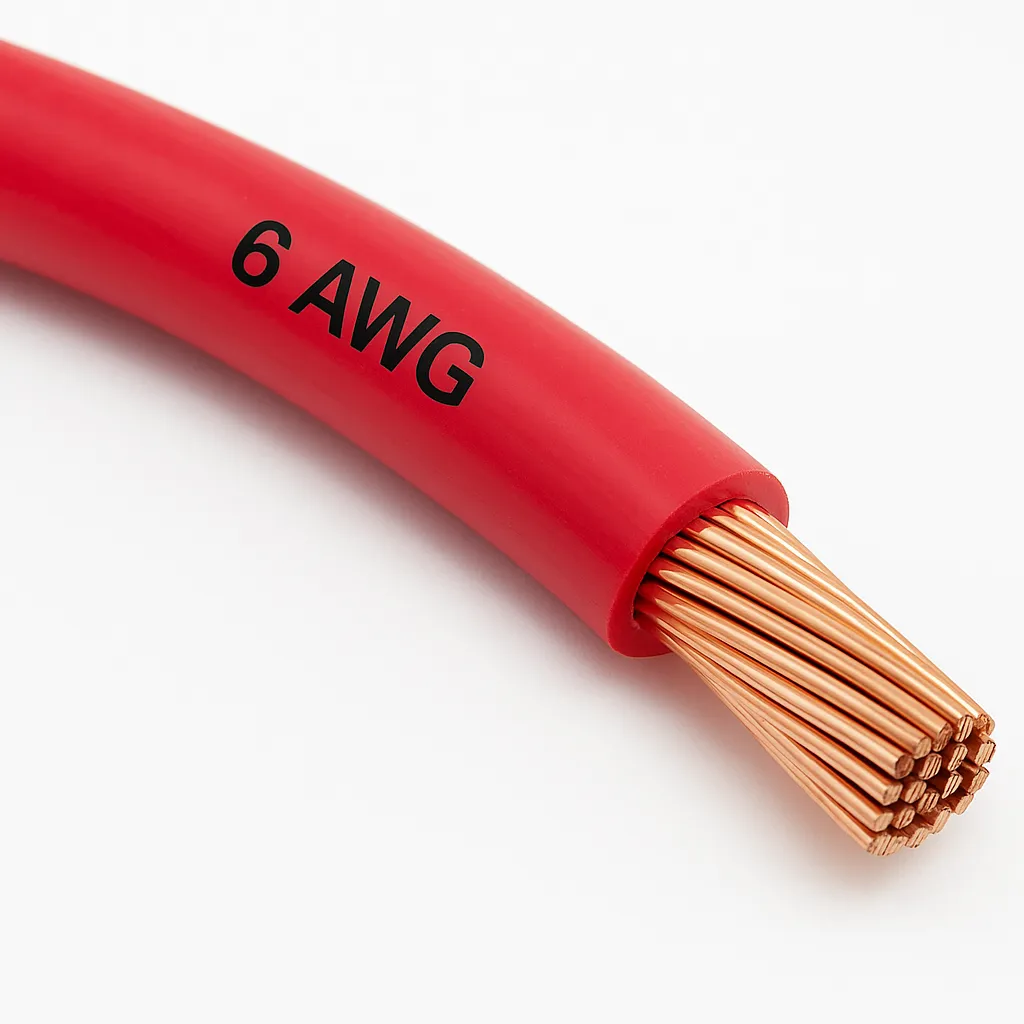

Understanding 6 AWG Wire: A Comprehensive Guide

Time: 2025-05-07 14:56:54

Source: Henan Province Jianyun Cable Co., Ltd.

What is the American Wire Gauge (AWG) System?

The American Wire Gauge (AWG) system is a standardized method for measuring the diameter of electrically conducting wire. It assigns a numerical designation to wires, where a smaller AWG number corresponds to a thicker wire with a larger cross-sectional area, capable of carrying more current. For example, a 6 AWG wire is thicker than a 12 AWG wire. The AWG system is widely used in North America and is critical for ensuring safe and efficient electrical installations.

What Are the Specifications of 6 AWG Wire?

A 6 AWG wire has specific physical characteristics that define its performance:

-

Diameter: Approximately 0.162 inches (4.11 mm).

-

Cross-Sectional Area: About 26.3 kcmil (13.3 mm²).

-

Weight: For copper, roughly 0.08 pounds per foot; for aluminum, about 0.03 pounds per foot.

These specifications make 6 AWG wire suitable for applications requiring moderate to high current capacity.

What is the Ampacity of 6 AWG Wire?

Ampacity refers to the maximum current a wire can safely carry without overheating. The ampacity of 6 AWG wire depends on the material, insulation type, and ambient conditions. According to the National Electrical Code (NEC):

-

Copper 6 AWG: Typically rated for 55-65 amps at 75°C (167°F) with common insulation types like THHN or THWN.

-

Aluminum 6 AWG: Rated for 40-50 amps under similar conditions.

Always consult NEC tables or a licensed electrician to determine the exact ampacity for your specific application, as factors like conduit use or ambient temperature can affect performance.

What Materials Are Used in 6 AWG Wire?

6 AW ببینید AWG wire is commonly made from two materials:

-

Copper: Offers excellent conductivity, making it ideal for most electrical applications. It is more expensive but supports higher current loads in smaller sizes.

-

Aluminum: Lighter and less costly than copper, but it has lower conductivity, requiring a larger gauge to carry the same current. Aluminum is often used in overhead power lines or large-scale installations.

The choice between copper and aluminum depends on cost, weight, and project requirements.

Solid vs. Stranded 6 AWG Wire: What's the Difference?

6 AWG wire can be either solid or stranded:

-

Solid Wire: Consists of a single, solid conductor. It is stiffer, less flexible, and often used in permanent installations like home wiring where minimal movement is expected.

-

Stranded Wire: Made of multiple smaller strands twisted together. It is more flexible, making it easier to route through conduits or use in applications requiring frequent bending, such as appliance cords.

Stranded 6 AWG wire is generally preferred for installations requiring flexibility, while solid wire may be chosen for cost savings in fixed setups.

What Are the Common Applications of 6 AWG Wire?

Due to its ability to handle significant current, 6 AWG wire is used in various applications, including:

-

Residential Wiring: For circuits powering heavy appliances like electric ranges, dryers, or HVAC systems.

-

Commercial Installations: In lighting circuits, subpanels, or equipment requiring robust power delivery.

-

Industrial Settings: For machinery or large motors where high current is needed.

-

Outdoor Use: In underground feeder (UF) cables or service entrance cables, often with weather-resistant insulation.

Always ensure the wire’s insulation type matches the environment (e.g., wet, dry, or high-temperature conditions).

What Safety Considerations Should Be Taken?

Working with 6 AWG wire requires adherence to safety standards to prevent electrical hazards:

-

Follow Local Codes: Comply with the NEC or other relevant electrical codes to ensure proper wire sizing and installation.

-

Use Proper Insulation: Select insulation rated for the environment, such as THWN for wet locations or THHN for dry, indoor use.

-

Avoid Overloading: Do not exceed the wire’s ampacity to prevent overheating or fire risks.

-

Professional Installation: For complex projects, hire a licensed electrician to ensure safety and compliance.

Regular inspections and maintenance can also help identify wear or damage in wiring systems.

Conclusion

The 6 AWG wire is a versatile and robust option for various electrical applications, offering a balance of current-carrying capacity and flexibility. By understanding its specifications, materials, and safety considerations, you can make informed decisions for your wiring projects. Always prioritize safety and compliance with local regulations to ensure reliable and hazard-free installations.