Time: 2025-05-13 15:33:15 Source: Henan Province Jianyun Cable Co., Ltd.

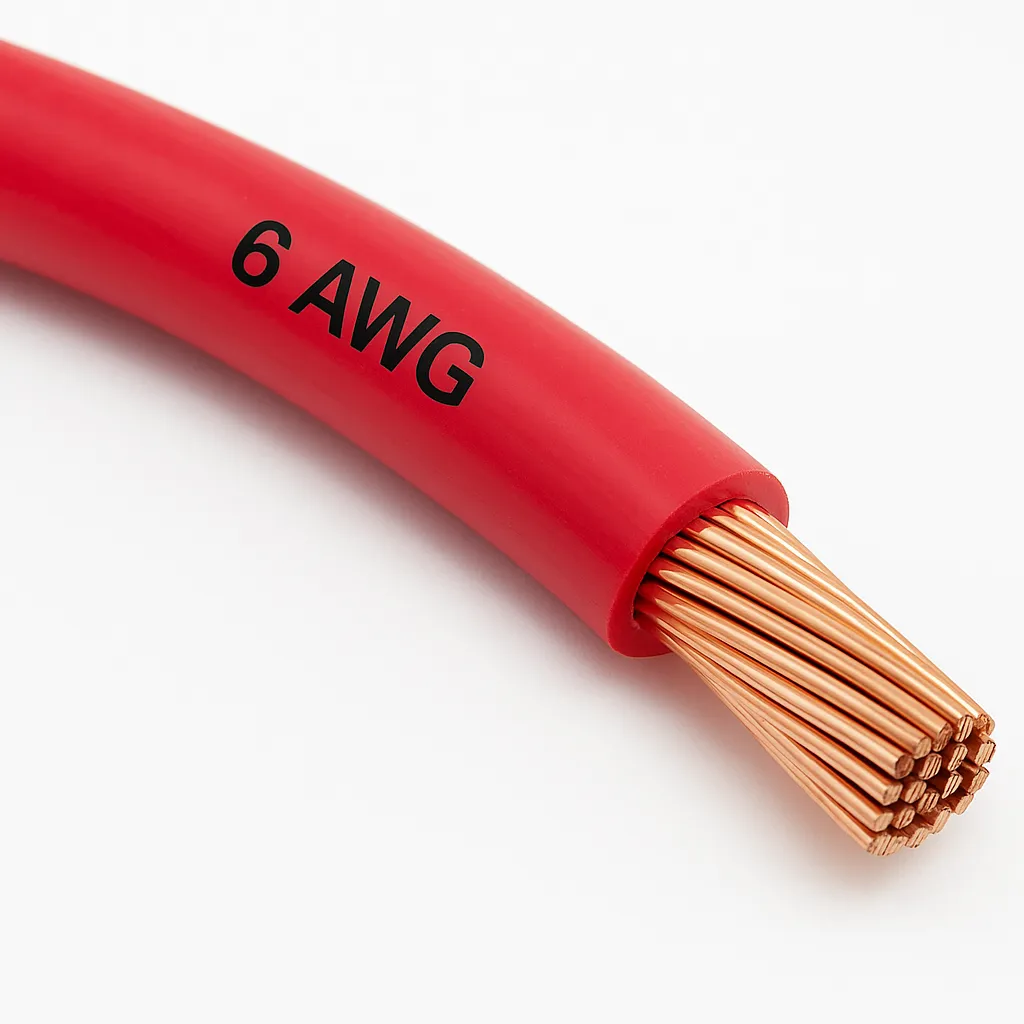

6 AWG (American Wire Gauge) wire is a standardized electrical conductor used for high-current applications in residential, commercial, and industrial settings. The AWG system, established in 1857, measures wire diameter inversely, meaning a lower AWG number indicates a thicker wire. With a conductor diameter of approximately 0.162 inches (4.11 mm) and a cross-sectional area of 13.3 mm², 6 AWG wire is thicker than 8 AWG (0.1285 inches) but thinner than 4 AWG (0.2043 inches). It is designed to handle currents typically ranging from 55 to 75 amps for copper conductors, depending on insulation and conditions, making it suitable for heavy appliances, subpanels, and industrial equipment. Its robust construction aligns with cables like THHN, RHW, or household wiring discussed previously, offering high conductivity and durability.

6 AWG wire is engineered for conductivity, durability, and safety, with key components:

Specifications include a voltage rating of up to 600V, a conductor resistance of approximately 1.3 Ω/km for copper, and compliance with standards like UL 83, UL 1063, and NEC. The wire’s outer diameter varies (e.g., 0.362 inches for 2000V DLO), depending on insulation thickness.

Ampacity, the maximum current a wire can carry without exceeding its temperature rating, depends on conductor material, insulation, and conditions (e.g., free air, conduit, ambient temperature). Per the 2020 National Electrical Code (NEC):

Factors reducing ampacity include bundling, high ambient temperatures (>30°C), or long runs causing voltage drop (e.g., 3% recommended for branch circuits). Copper’s higher conductivity makes it preferred over aluminum for minimizing resistance (1.3 Ω/km vs. 2.1 Ω/km). Voltage drop calculations are critical for runs over 50 feet, requiring larger gauges like 4 AWG for extended distances, similar to considerations for MV or submarine cables.

6 AWG wire is versatile for high-current applications, including:

Its 55–75 amp capacity suits 50A–60A breakers (per NEC 80% rule), making it ideal for demanding loads, unlike thinner 12 AWG or 14 AWG wires.

Safe use of 6 AWG wire requires adherence to electrical codes and best practices:

These measures ensure safety and reliability, aligning with the focus on LSOH, grounding, or halogen-free cables.

6 AWG wire differs from other gauges in size, ampacity, and applications. The table below compares it to 8 AWG and 4 AWG:

| Feature | 8 AWG | 6 AWG | 4 AWG |

|---|---|---|---|

| Conductor Diameter | 0.1285 in (3.26 mm) | 0.162 in (4.11 mm) | 0.2043 in (5.19 mm) |

| Cross-Sectional Area | 8.37 mm² | 13.3 mm² | 21.15 mm² |

| Copper Ampacity (75°C) | 50A | 65A | 85A |

| Aluminum Ampacity (75°C) | 40A | 50A | 65A |

| Resistance (Copper, Ω/km) | 2.1 | 1.3 | 0.82 |

| Applications | Lighting, small appliances | Subpanels, HVAC, hot tubs | Large motors, main feeders |

| Cost | Lower | Moderate | Higher |

Note: Ampacity based on NEC 2020 for 75°C insulation in conduit. Verify with NEC or electrician for specific conditions.

Selecting the right 6 AWG wire ensures performance and safety:

These steps ensure reliable wiring, akin to selecting THHN, LSOH, or trailing cables.

6 AWG wire is a robust and versatile conductor for high-current applications, offering a balance of size, ampacity (55–75A for copper), and durability. Its copper or aluminum conductors, paired with insulation like THHN, THWN-2, or XHHW, support diverse uses, from residential subpanels and HVAC systems to industrial machinery and solar installations. Compliance with NEC and UL standards, proper sizing, grounding, and professional installation are critical to prevent overheating, voltage drop, or faults. Compared to 8 AWG or 4 AWG, 6 AWG strikes a cost-effective balance for 50A–60A circuits, aligning with the safety and performance of cables like THHN, RHW, or household wiring discussed previously. By selecting the right insulation, conductor, and installation practices, users can ensure safe and efficient power delivery for demanding electrical projects.