Cable Bending Radius: Why It Matters and How to Calculate It

Time: 2025-06-19 15:25:25

Source: Henan Province Jianyun Cable Co., Ltd.

Overview of Cable Bending Radius

The cable bending radius is the minimum radius a cable can be bent without compromising its structural integrity or electrical performance. It is typically expressed as a multiple of the cable’s outer diameter (OD). Adhering to the correct bending radius is essential during installation to prevent damage to conductors, insulation, or sheathing, ensuring long-term reliability and safety in applications such as power distribution, telecommunications, and renewable energy systems.

Why Bending Radius Matters

Proper management of the bending radius is critical for several reasons:

-

Prevents Physical Damage: Excessive bending can crush or kink conductors, crack insulation, or split sheathing, leading to electrical faults or insulation failure.

-

Maintains Electrical Performance: Over-bending can alter conductor geometry, increasing resistance or impedance, which may degrade signal quality or cause overheating.

-

Ensures Safety: Damaged cables pose risks of short circuits, electrical fires, or shock hazards, particularly in high-voltage installations.

-

Extends Cable Lifespan: Adhering to the recommended bending radius reduces mechanical stress, enhancing durability and reducing maintenance costs.

-

Ensures Compliance: Meeting industry standards, such as those set by the National Electrical Code (NEC) or International Electrotechnical Commission (IEC), avoids regulatory penalties and project delays.

Improper bending can lead to costly repairs, system downtime, or safety violations, making it a critical consideration during cable installation.

Factors Affecting Bending Radius

Cable Type and Construction

Different cable types have varying flexibility and bending requirements:

-

Power Cables: Multi-conductor or armored cables are stiffer, requiring larger bending radii (e.g., 6–12 times OD).

-

Data Cables: Coaxial or twisted-pair cables (e.g., Cat6) are more flexible but sensitive to signal degradation, typically requiring 4–6 times OD.

-

Fiber Optic Cables: Highly sensitive to bending, often requiring 10–20 times OD to prevent signal loss or fiber breakage.

The number of conductors and presence of shielding or armor also influence flexibility.

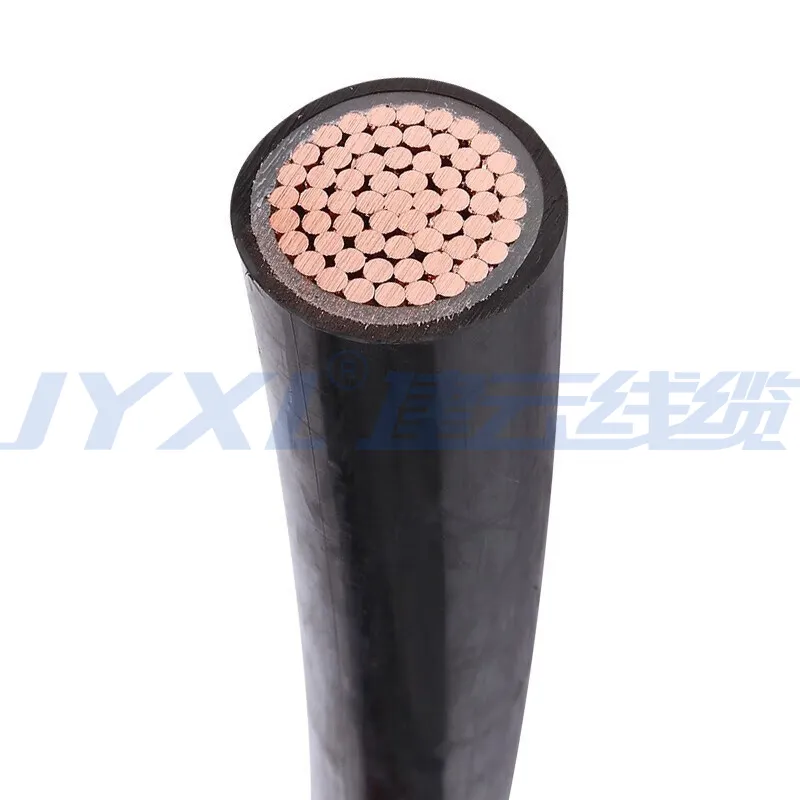

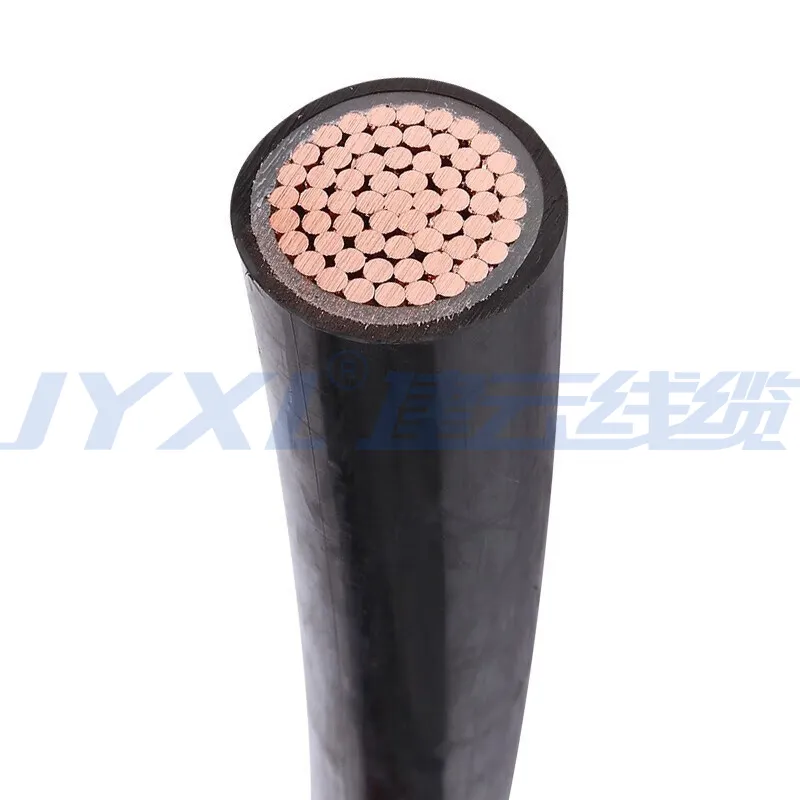

Conductor Material

The conductor material affects the cable’s flexibility:

-

Copper: More flexible than aluminum, allowing tighter bends for the same size.

-

Aluminum: Stiffer and prone to cracking under tight bends, requiring larger radii.

-

Stranded vs. Solid Conductors: Stranded conductors are more flexible, permitting smaller bending radii compared to solid conductors.

Insulation and Sheathing

Insulation and sheathing materials impact bending characteristics:

-

PVC or XLPE: Common insulation materials with moderate flexibility, suitable for standard bending radii.

-

Rubber or TPE: More flexible, allowing tighter bends, often used in dynamic applications.

-

Low-Smoke Zero-Halogen (LSZH): Stiffer than PVC, requiring larger radii to avoid cracking.

Thicker insulation or sheathing increases the cable’s OD, necessitating larger bending radii.

Installation Type

The installation environment and application influence bending radius requirements:

-

Fixed Installations: Cables bent once during installation (e.g., in conduits) use the minimum bending radius, typically 4–8 times OD.

-

Dynamic Installations: Cables subject to repeated flexing (e.g., in robotics) require larger radii, often 10–15 times OD, to prevent fatigue.

-

Environmental Conditions: Extreme temperatures or exposure to chemicals can stiffen cables, necessitating larger radii.

How to Calculate Bending Radius

The bending radius is calculated by multiplying the cable’s outer diameter (OD) by a factor specified by the manufacturer or industry standard. The process is as follows:

-

Measure the Cable’s Outer Diameter: Use a caliper or refer to the manufacturer’s datasheet to determine the OD in millimeters or inches.

-

Identify the Bending Radius Factor: Consult the cable’s technical specifications or standards (e.g., NEC, IEC, or TIA). Common factors include:

-

Power cables: 6–12 times OD

-

Data cables: 4–6 times OD

-

Fiber optic cables: 10–20 times OD

-

Dynamic applications: 10–15 times OD

-

Calculate the Minimum Bending Radius: Multiply the OD by the factor. For example, a power cable with an OD of 10 mm and a factor of 8 requires a minimum bending radius of 10 × 8 = 80 mm.

-

Verify Installation Conditions: Adjust the radius if dynamic flexing, high temperatures, or other factors apply, using manufacturer guidelines.

-

Check Physical Constraints: Ensure the installation space (e.g., conduit, tray, or bend path) accommodates the calculated radius.

Example: A Cat6 cable with an OD of 6 mm and a bending factor of 4 has a minimum bending radius of 6 × 4 = 24 mm. Bends tighter than this may degrade signal performance.

Industry Standards and Guidelines

Adhering to industry standards ensures proper bending radius compliance:

-

NEC (US): Specifies minimum bending radii for power cables in Article 300.34 (e.g., 12 times OD for shielded cables over 1000V).

-

IEC 60287 (Global): Provides guidelines for power cable installations, including bending radii based on cable construction.

-

TIA-568 (Telecommunications): Recommends bending radii for data cables, such as 4 times OD for twisted-pair cables.

-

IEC 60794 (Fiber Optics): Specifies 10–20 times OD for fiber optic cables to prevent signal loss.

Manufacturer datasheets often provide specific bending radius recommendations, which should take precedence if stricter than standards.

Common Mistakes to Avoid

-

Ignoring Manufacturer Specifications: Using generic bending radii instead of cable-specific guidelines can damage cables.

-

Over-Bending During Installation: Tight bends to fit confined spaces may cause immediate or long-term damage.

-

Neglecting Dynamic Applications: Using fixed installation radii for cables subject to flexing leads to premature failure.

-

Failing to Measure OD: Estimating cable diameter can result in incorrect radius calculations.

-

Overlooking Environmental Factors: Extreme temperatures or chemical exposure can alter flexibility, requiring larger radii.

Summary Table: Bending Radius Considerations

|

Factor

|

Impact on Bending Radius

|

Recommendation

|

|

Cable Type

|

Power, data, or fiber optic cables vary in flexibility

|

Use 4–20 times OD based on type

|

|

Conductor Material

|

Aluminum is stiffer than copper

|

Allow larger radii for aluminum

|

|

Insulation/Sheathing

|

Thicker or stiffer materials increase radius

|

Check material-specific guidelines

|

|

Installation Type

|

Dynamic applications need larger radii

|

Use 10–15 times OD for flexing

|

Conclusion

Understanding and adhering to the correct cable bending radius is essential for ensuring the safety, performance, and longevity of cable installations. By considering factors such as cable type, conductor material, insulation, and installation conditions, and calculating the radius based on manufacturer specifications or industry standards, installers can prevent damage and maintain system reliability. Partnering with reputable suppliers like Jianyun Cable provides access to high-quality cables with clear bending radius guidelines, supporting compliant and durable installations. Avoiding common mistakes, such as over-bending or ignoring dynamic requirements, ensures successful project outcomes across various applications.